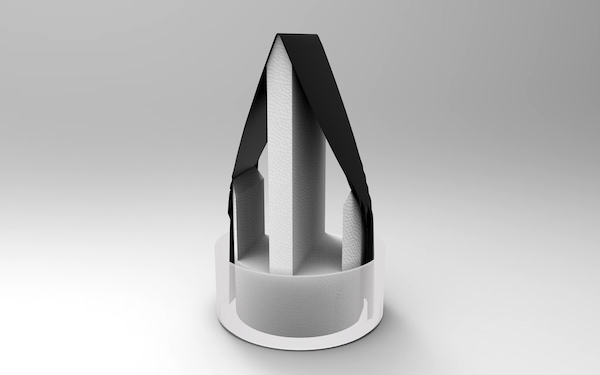

[Image above] The bottom edges of a carbon-dipped paper formed into an inverted “V” soak up water while the carbon coating absorbs solar energy—transforming it into heat for evaporation. Credit: Huaxiu Chen; University of Buffalo

Water is an essential element of life, but many people around the world don’t have access to clean drinkable water.

Researchers are working to change that—last year we reported on a student who used his ceramics knowledge to help citizens in Uganda develop a ceramic filtration method to purify water.

Ceramics were also front and center in a research collaboration that developed a ceramic sponge offering possibilities for water filtration applications.

But these kinds of ceramics aren’t the only materials and methods researchers are experimenting with for water purification.

Scientists have already succeeded in purifying water with carbon nanotubes. And, in other research, scientists are actually harnessing the power of the sun in a membrane distillation process to purify water.

Now, researchers have created a novel water purification process using the sun’s energy and carbon-coated paper. In a collaboration between the University of Buffalo, Fudan University (China), and the University of Wisconsin-Madison, scientists have developed a process that uses sunlight to produce clean water with a little help from our friend, carbon.

“Our technique is able to produce drinking water at a faster pace than is theoretically calculated under natural sunlight,” lead researcher Qiaoqiang Gan, associate professor of electrical engineering in the University at Buffalo School of Engineering and Applied Sciences, explains in a university news release.

The team’s device consists of paper dipped in carbon and draped into an inverted “V” shape over a container of water, similar in shape to the roof of a birdhouse. The bottom of the paper soaks up water, while the carbon coating absorbs the sun’s energy and turns it into heat for evaporation, according to a description in the release.

The paper’s sloped geometry keeps it cool by weakening the intensity of light illuminating it. This architecture helps to speed vapor and water generation in experiments. Credit: Youhai Liu; University of Buffalo

The method is essentially an updated version of traditional solar stills that use solar energy to evaporate water. Mine owners in Chile were using solar stills to distill water to provide clean drinking water for their workers as early as the 19thcentury. Gan says the team’s device can achieve a higher efficiency because it draws heat in.

What makes the scientists’ method successful is that they improved the inefficient vaporization process of solar stills, where the inverted V shape of carbon-coated paper enables heat to be drawn in from the immediate environment while staying at room temperature.

“Usually, when solar energy is used to evaporate water, some of the energy is wasted as heat is lost to the surrounding environment,” he says in the release. “This makes the process less than 100% efficient. Our system has a way of drawing heat in from the surrounding environment, allowing us to achieve near-perfect efficiency.”

Not only is the method low-cost and close to 100% efficient, it could provide purified water for third-world countries needing access to clean water or for areas cut off from water sources due to natural disasters, such as hurricanes, tornadoes, or floods.

UB electrical engineering Ph.D. graduate and coauthor of the paper Haomin Song says the method could eventually be scalable for those types of situations. “We have a strategy to boost daily performance,” Song says. “With a solar still the size of a mini fridge, we estimate that we can generate 10 to 20 liters of clean water every single day.”

In fact, the team’s startup, Sunny Clean Water, is a first step toward that effort.

The open-access paper, published in Advanced Science, is “Cold vapor generation beyond the input solar energy limit” (DOI: 10.1002/advs.201800222).

Want to read more articles like this? Subscribe to the Ceramic Tech Today newsletter to continue to receive the latest news in the ceramic and glass industry right in your inbox! Visit this link to get started.