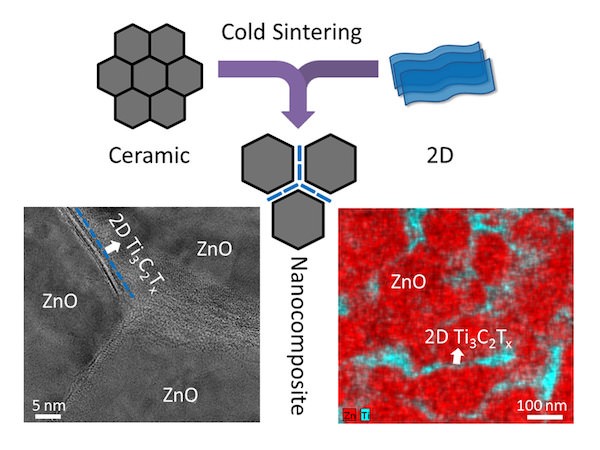

[Image above] The schematic illustration showing the co-sintering of ceramics and 2D materials using cold sintering processing, and TEM image and energy dispersive spectroscopy (EDS) map of cold sintered 99ZnO-1Ti3C2Tx nanocomposite. The MXene nanosheets are distributed homogeneously along the ZnO grain boundaries, as seen in the TEM image and EDS map. Credit: MRI/Penn State

Materials scientists invented composites to marry dissimilar materials and gain a new material whose sum is greater than the parts. It’s a smart strategy that has proven effective with many materials and many applications. Familiar examples are everywhere—SiC–SiC composites, cemented carbide cutting tools, fiberglass reinforced polymers, etc.

But, composites aren’t always so easy to make. Like a good marriage, there has to be enough contrast to make the union interesting and useful, but enough compatibility for the materials to work together. When it comes to composites with ceramic constituents, compatibility during processing can limit the types of materials that can be joined together, especially if synthesis involves heat.

A new paper published in Advanced Materials shows that thermal processing may cease to be a barrier thanks to recent advances in cold sintering processing (CSP). And, the paper reports success making composites with wildly dissimilar materials. Each constituent brings functional properties, and the composite’s properties are better than either constituent alone—a hallmark of a good marriage.

The research collaboration between Clive Randall’s group at Pennsylvania State University and Yury Gogotsi’s group at Drexel University demonstrated the feasibility of using cold sintering to densify a composite of zinc oxide and the MXene compound, Ti3C2Tx. The collaboration sprouted from an NSF-sponsored workshop on the role of ceramics and glass on meeting society’s grand challenges, which both researchers attended.

MXenes are 2-D transition metal carbides, nitrides, or carbonitrides made by selectively etching MAX phases. Their properties can be tuned with selection of the metallic elements—transition metal M (Ti, V, Cr, Ta, Mo, Nb, etc.,) and group A element (Al, Si, Sn, In, etc.). The etchant leaves surface functional groups, which can be engineered for desired surface reactivity. In the chemical formula, Tx designates the surface-terminating functional group: oxygen, hydroxyl, or fluorine.

MXenes have near-metallic conductivity, but are susceptible to oxidation, especially at elevated temperatures. Zinc oxide is semiconducting, but susceptible to uneven grain growth during sintering, typically at temperatures approaching 1,000°C.

Cold sintering densifies ceramics at temperatures up to 300°C by balancing mass transport driven by temperature, pressure, time, and water content. At those temperatures, materials scientists can think of composites made with unexpected constituent pairings.

Graduate students from the two groups made continuous-matrix composites by combining 0.5–5 wt% MXene with ZnO nanoparticles. Interestingly, the composite performed better than either constituent alone. That is, the two materials worked together to make a composite with better properties than either material alone has.

The press release summarizes the impressive results: “The metallic MXene coated the ceramic powder and formed continuous two-dimensional grain boundaries, which prevented grain growth, increased the conductivity by two orders of magnitude, transforming semiconducting zinc oxide into a metallic ceramic, and doubled hardness of the final product. The addition of MXene also improved the ability of zinc oxide to transform heat to electricity.”

“This is one of a series of examples showing the ability to design grain boundaries in ways we previously couldn’t do,” Randall says in an interview. “Now we can be proactive, adding unusual phases not even in the phase diagram and dissimilar phases.”

“This is the first ceramic composite containing MXene,” Gogotsi says in the release. “Taking into account that about thirty MXenes with diverse properties are already available, we are opening a new chapter in research on ceramic matrix composites, with potential applications ranging from electronics to batteries and thermoelectrics.”

The paper is “Cold sintered ceramic nanocomposites of 2D MXene and zinc oxide,” by Jing Guo, et al., Advanced Materials (DOI: 10.1002/adma.201801846

Want to read more articles like this? Subscribe to the Ceramic Tech Today newsletter to continue to receive the latest news in the ceramic and glass industry right in your inbox! Visit this link to get started.