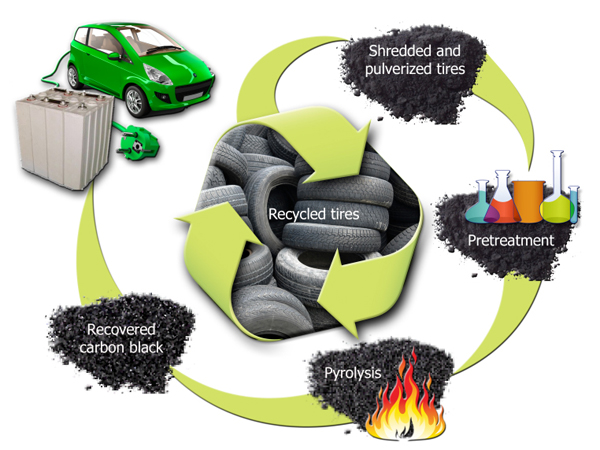

[Image above] Old tires have found new purpose in helping to better a better anode for lithium-ion batteries. Credit: Mykl Roventine; Flickr; CC BY-NC-SA 2.0

Flat, funky, or downright tired tires are finally good for something other than playground equipment or garden planters.

In fact, researchers at Oak Ridge National Laboratory (ORNL) say they might be the perfect material to help build a better anode—a leading component for lithium-ion batteries.

That’s right: The recycled rubber we so readily discard—some 290 million each year—could someday provide electricity to our electric vehicles or store solar or wind energy.

The team, led by ACerS and Electronics Division member Parans Paranthaman and Amit Naskar, are working to build that better anode by modifying the microstructure of the carbon black found in old tires.

Published in RSC Advances, the team’s approach is preferable to conventional methods for making anodes for Li-ions, says Paranthaman.

“Using waste tires for products such as energy storage is very attractive not only from the carbon materials recovery perspective, but also for controlling environmental hazards caused by waste tire stock piles,” he says in an ORNL news release.

According to the release, “The ORNL technique uses a proprietary pretreatment to recover pyrolytic carbon black material, which is similar to graphite but man-made. When used in anodes of lithium-ion batteries, researchers produced a small, laboratory-scale battery with a reversible capacity that is higher than what is possible with commercial graphite materials.”

After 100 cycles, the carbon anode’s “unique microstructure” outperformed graphite, boasting a capacity of close to 390 millamp hours per gram.

“This kind of performance is highly encouraging, especially in light of the fact that the global battery market for vehicles and military applications is approaching $78 billion and the materials market is expected to hit $11 billion in 2018,” says Paranthaman.

The team believes their new method could remove some of the hurdles of producing an anode with a high-surface area, higher-rate capability, and long-term stability.

ORNL plans to work with industry to license the technology and has posted a business opportunity solution here, available until September 15.

The paper is “Tailored recovery of carbons from waste tires for enhanced performance as anodes in lithium-ion batteries,” (DOI: 10.1039/C4RA03888F).