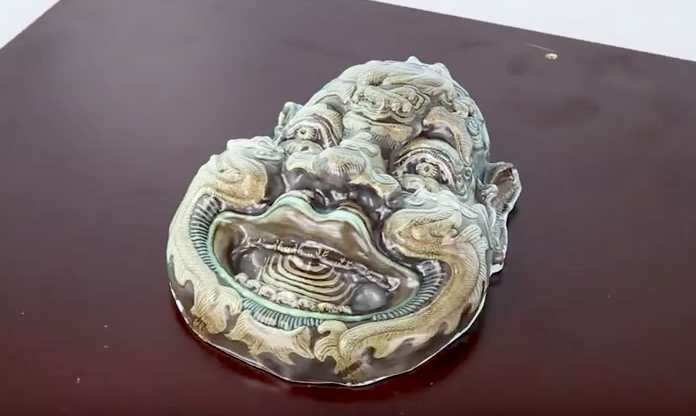

[Image above] Finished replica of a Chinese mask using the new computational thermoforming method developed by researchers from ETH Zürich and Disney Research Zürich. Credit: Christian Schiller; YouTube

Can a technique used to manufacture common molded parts, like yogurt containers and packaging for electronics, serve as a more cost-effective alternative to mass 3D printing?

Researchers at ETH Zürich and Disney Research Zürich say yes.

Using a combination of new software and an established industrial production technique called thermoforming, the method allows quick, cheap production of individual pieces or small batches of objects with structurally complex and colored surfaces, explains an ETH Zürich news release about the work.

The method uses a 3D printer to produce a negative mold of a model made of polylactic acid, a single-color plastic, the release explains. This mold is used to create a positive mold made of gypsum that’s able to the resist the heat used in the thermoforming process.

Software computes the precise texture for the 3D model, which is printed with a standard laser printer onto special transfer paper. The transfer paper is placed on a plastic sheet, heat and pressure are applied, and the 2D image color is transferred onto the plastic.

From there, the plastic sheet is secured in a thermoforming machine above the gypsum mold and heated until pliable. Air from between the sheet and the gypsum cast is vacuumed out, which sets the plastic tight against the gypsum mold to make the replica.

As the plastic sheet molds to the gypsum model, it deforms and changes the original printed image. But the team has this covered.

“Our software accurately calculates and compensates for this deformation,” says ETH doctoral student Christian Schüller, one of the lead researchers.

Some of the complex objects tested with this technique include a Chinese mask, a car body shell, and food replicas.

The team will present their research at the 43rd International Conference and Exhibition on Computer Graphics and Interactive Techniques in Anaheim, Calif., July 24–28.

Check out this video of the technique in action!

Credit: Christian Schüller; YouTube