If you think about it, water molecules are a great place to store hydrogen. Now that the “hydrogen economy” is starting to get some traction, the question is how to get the hydrogen “out of storage.” One way to unlock the hydrogen is photoelectrolysis—using the sunlight to split the water. The photoelectrolysis process involves capturing sunlight, converting it to current, using the electrical current to split the water molecule and harvest out the hydrogen. Some semiconducting materials are able to convert sunlight into charge carriers, i.e., current.

Because we expect to need a lot of hydrogen, we are going to need a lot of semiconducting material that is stable in aqueous environments, nontoxic, abundant, inexpensive and able to absorb visible light. Rust, in thin film form, meets those requirements. Alpha-Fe2O3 (hematite), however, has poor transport properties, and the “photogenerated” charge carriers generally recombine before they can be used to do any work.

Researchers at the Technion-Israel Institute of Technology may have found a way around the recombination problem in photoelectrolysis anodes, or photoanodes, according to a new paper published in Nature Materials. In a press release, lead researcher Avner Rothschild, associate professor in the Institute’s department of materials science and engineering, says “Our light-trapping scheme overcomes this tradeoff [between light absorption and charge carrier recombination], enabling efficient absorption in ultrathin films wherein the photogenerated charge carriers are collected efficiently.”

The efficiency of the 20-30 nanometer thick alpha-Fe2O3 films has two sources. First, according to the paper’s abstract, the films are designed as optical cavities that trap light and efficiently collect the charge carriers. The penetration depth of visible light in iron oxide is about a micrometer, but the photogenerated charge carriers are only collected in a 2 to 20 nanometer range. So, the key is to push, or trap, the light into a 20 nanometer range that is located near the place where the charge is needed, that is, a surface.

Rothschild explains:

The light is trapped in quarter-wave or even deeper sub-wavelength films on mirror-like back reflector substrates. Interference between forward- and backward-propagating waves enhances the light absorption close to the surface wherein the photogenerated charge carriers are collected before recombination takes place. The escaped (back reflected) photons are re-trapped by a second ultrathin film photoanode in front of the first photoanode, thereby leading to efficient photon harvesting using 20-30 nm thick alpha-Fe2O3 films.

In this way, the light intensity is amplified near the surface of the photoanode, where it oxidizes the water before recombining.

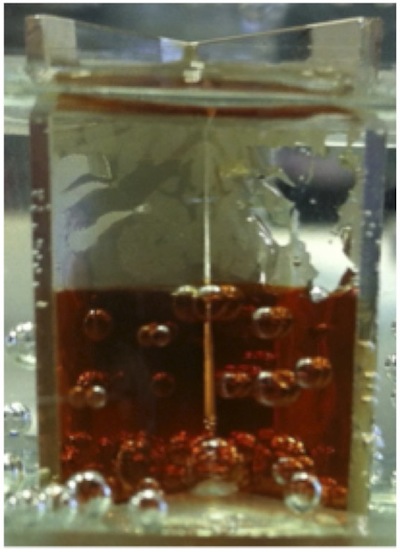

The second aspect to maximizing efficiency involves smart design of the photoanode geometry. The abstract reports that V-shaped cells, for example, are especially efficient at harvesting light in these ultrathin films.

Rothschild says the new technology could lead to cost-effective, integrated solar cells that combine the ultrathin iron oxide photoelectrodes with standard silicon-based solar cells and thereby produce both electricity and hydrogen. He also says the light-trapping research could reduce the need for rare elements in so-called “second generation” photovoltaic cells, such as tellurium in CdTe cells or indium in Cu-In-Ga-Se cells.

The paper is “Resonant light trapping in ultrathin films for water splitting,” H. Dotan, O. Kfir, E. Sharlin, O. Blank, M. Gross, I. Dumchin, G. Ankonina and A. Rothschild, Nature Materials, doi: 10.1038/nmat3477.

[Editor’s update: We just became aware of this You Tube video where Rothschild describes his work. including a demonstration of the photoanode as it “makes” hydrogen.]