The 2024 Pan American Ceramics Congress and Ferroelectrics Meeting of Americas took place April 7–11 in Panama City, Panama. The conference witnessed a surge in attendance compared to 2022 and welcomed a record-number of students from South American countries.

Read MoreWhat gives colored glass its brilliant hues? Since the early days of alchemy, our understanding of and control over the design of colored glasses has improved enormously, opening the door to a host of practical applications.

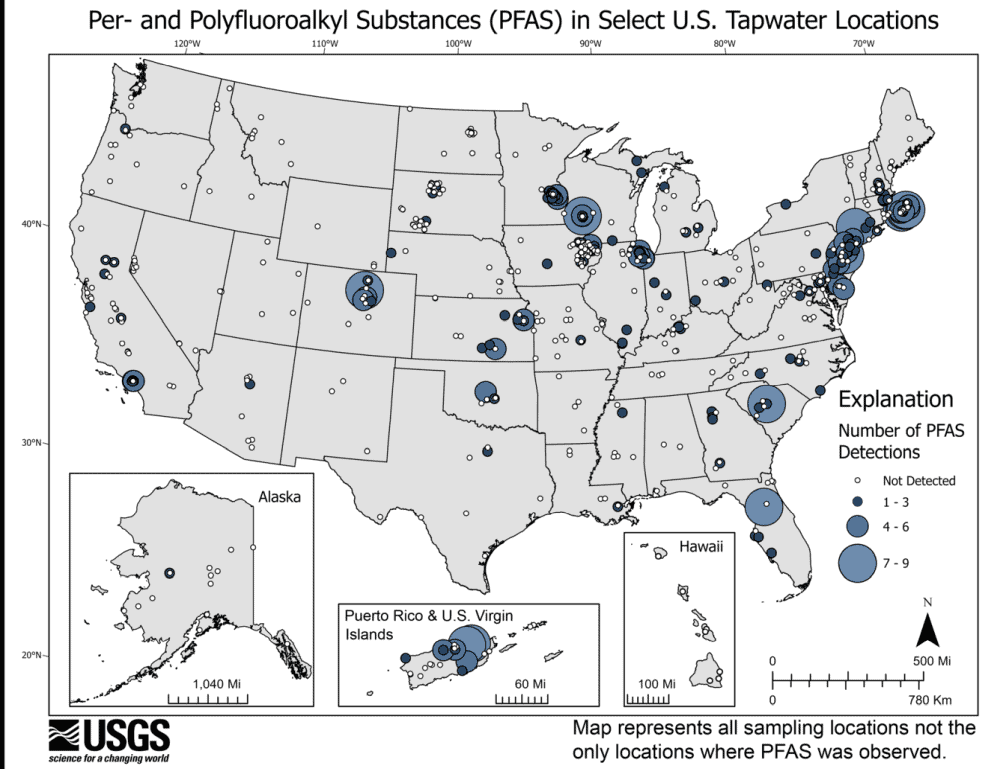

Read MoreOn April 10, 2024, the U.S. Environmental Protection Agency issued the first legally enforceable national drinking water standards for several common types of PFAS chemicals. Learn what the new standards mean for U.S. drinking water and how ceramics may play a role in the cleanup efforts.

Read MoreMagnetic nanographene butterfly, resistance-free electron channels, and other materials stories that may be of interest for April 17, 2024.

Read MoreThough the tradition of creating grand stained-glass windows is less common than it was before, the artform remains an important part of our culture today. In April 2024, CTT is running a special three-part series on stained glass. Part 2 provides an overview of the early history of colored glass and details the rise and fall of stained-glass windows between the 11th and 16th centuries.

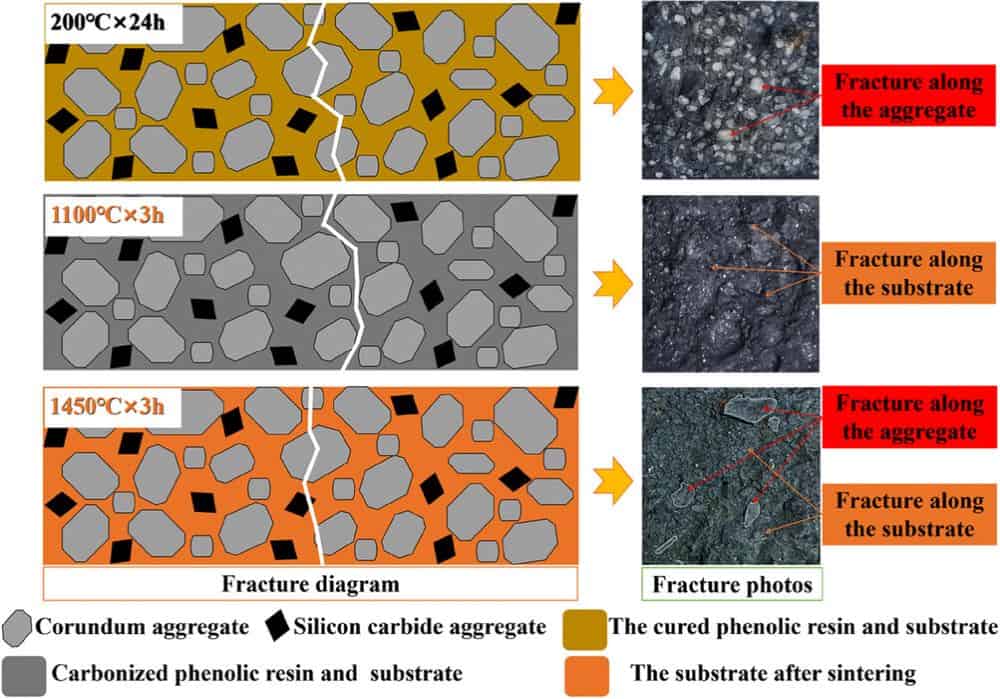

Read MoreThe choice of starting material for refractory ceramics can greatly affect the product’s final properties. Researchers from Wuhan University of Science and Technology in China investigated the effects of different corundum aggregates on Al2O3-SiC-C bricks.

Read MoreTo celebrate this year’s National Robotics Week, we have curated some of our past CTTs featuring fun innovations in robot technology.

Read MoreSubterranean storage of hydrogen, 3D print unknown materials, and other materials stories that may be of interest for April 10, 2024.

Read MoreACerS Greater Missouri Section and Refractory Ceramics Division held the 59th Annual Symposium on Refractories in St. Louis, Mo., March 26–28, 2024. Almost 240 members of the refractory ceramics community attended the meeting, which focused on unleashing refractory potential through root cause analysis.

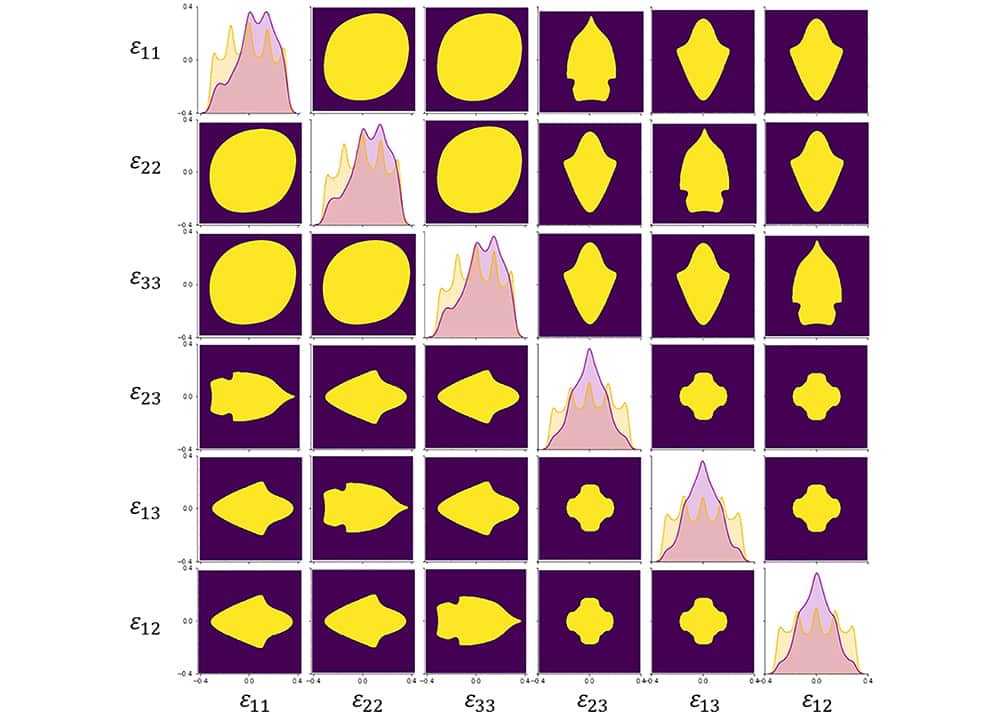

Read MoreElastic strain engineering has potential to improve processing performance in the semiconductor industry. Researchers led by Nanyang Technological University in Singapore and Massachusetts Institute of Technology used machine learning to create a map that shows how to tune the thermal and electronic properties of crystalline materials via strain engineering.

Read More