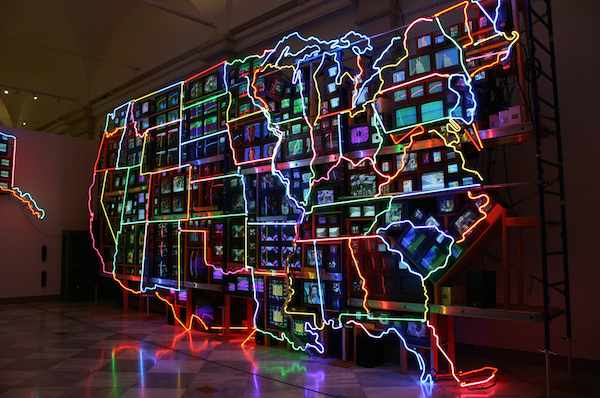

What does manufacturing mean to America? Credit: NAMvideo on Youtube.

What does manufacturing mean to you? Watch the video above from the National Association of Manufacturers for some inspiration.

My fellow editors Jessica and Eileen also recently reported just how important manufacturing is in America, so it’s perhaps not surprising that a recent National Association of Manufacturers/IndustryWeek Survey of Manufacturers revealed an upbeat attitude for the future.

Christine Furstoss, Global Technology Director of Manufacturing & Materials Technology at GE Global Research, seems pretty upbeat about the future, too. Furstoss recently wrote on GE’s blog that innovation never stops at GE. “And with manufacturing competitiveness greater than ever, we don’t have a minute to spare,” she says.

To highlight her point, Furstoss posted a video of some of GE’s recent innovations across the globe. In brief, those innovations include:

- Direct writing—Printing “miniaturized sensors” directly onto parts in places and ways that were previously impossible.

- Automotive automation—Innovative robotic processes to allow automated, leaner, and faster manufacture of large, complex components, like engine parts.

- Electrical discharge machining—Strategic and incredibly precise drilling that helps hot metal parts keep their cool.

- CT materials scans—Using computed tomography (CT), a medical technology, to assess the “health” of materials and detect microstructure defects.

- Factory robotics—Innovative and specialized robotics to replace manual processes for faster and more reliable factory tasks

GE seems to know that manufacturing success is spurred by innovation. But research from the Sauder School of Business at the University of British Columbia recently found that innovation also can thwart success when corporate leaders take on a herd mentality, adopting innovation primarily because of competitor activity.

“Business leaders tend to panic when new innovations are about to hit the market. They scramble to buy an apparent early leader,” says business professor Marc-David Seidel, who led the study. Instead, the study says that leaders should first scrutinize innovations before embracing them.

And while we’re talking innovation, a recent comment published in Nature suggests that industry-funded academic research boosts innovation—contrary to concerns that such partnerships restrict innovation and knowledge transfer.

Those authors write: “Another surprise is that corporate-sponsored inventions spur more ‘knowledge spillovers,’ on average, than federally sponsored research, according to forward citation rates, the most widely used metric for patent quality and value. …This runs counter to the expectation that corporate-sponsored inventions have narrow applications, and so create more private benefits but few benefits for others.”

But what makes a manufacturing company like GE not only innovative, but also so successful?

The 2014 Manufacturing Training Trends Survey, recently released by Seminars for Engineering, reports that respondents say lack of training is the number one component fettering manufacturing success.

Over a quarter of survey respondents say that lack of training is the biggest obstacle to manufacturing quality success, according to the report. Further, 81 percent of respondents wish their company offered more technical training opportunities. As to why, respondents cited that additional training would improve productivity (34 percent), produce fewer manufacturing defects (27 percent), improve morale (20 percent), and provide greater satisfaction with management (20 percent).

And although online training sessions or webinars have gained popularity, the majority of respondents maintained that in-person training is both most common and most valuable.

So, what do you think is the recipe for success? Industry and thought leaders are sure to provide their insights at the 4th Ceramic Leadership Summit on April 7-9—there’s still time to register, so secure your spot today!

Feature image credit: Ryan Somma on Flickr.