Credit: Sherman Tan, Wikimedia Creative Commons License.

In the short time that I’ve been writing at The American Ceramic Society, I’ve been amazed by the prevalence of ceramics in our everyday lives. Yet most people don’t seem to know what ceramics are—I surely couldn’t define ceramics or appreciate their ubiquity in the not-too-distant past.

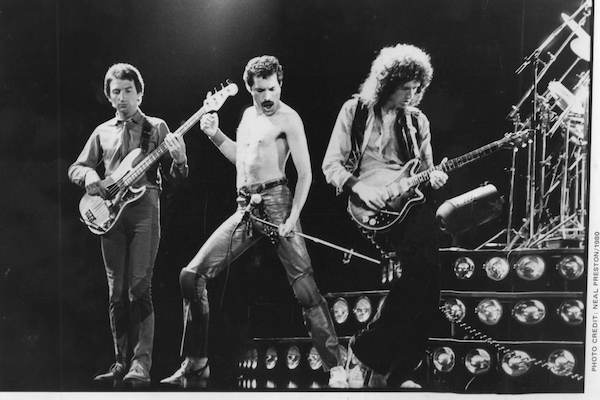

If ceramics were in a band, they would definitely be the drummer—thanklessly keeping the beat, providing structure and foundation. No one pays the ceramics any attention though, because they’re too busy staring at the flashy bare-chested heavy metal lead singer holding the mic.

Queen drummer Roger Taylor didn’t even make the photo. (Freddie Mercury—get it?)

Credit: Neal Preston/1980.

But ceramics provide a foundation or at least play a contributing role in most everything we do. Check your smartphone? Turn on a light? Use a computer? Ride in a car? An airplane? Enjoy electricity? Use a bathroom? Thank ceramics.

I was amazed to recently learn one more place that ceramics are hiding—pavement markings.

Pavement markings are essential to road safety—they guide us along our journeys from here to there. Many of us get in our cars and drive to work every day, but when was the last time you actually paid attention to one of the most important parts of the road? Probably only when they were missing or in need of repair.

Recent headlines about the installation of glowing road markings in the Netherlands got me thinking about pavement markings (more about that below). And wouldn’t you know—glass and ceramic materials are an integral part of pavement markings.

Standard pavement markings used by the Department of Transportation (ODOT) here in Ohio, and in many other states across the US, incorporate glass beads with pavement paint to achieve that easy-to-spot reflectivity (which is called retroreflectivity). If you’ve been on a dark road with old markings that aren’t very visible, you can surely appreciate that feature.

ODOT incorporates glass beads into several of their pavement marking paints, with different bead specifications depending on the type of paint used. The beads are silicon dioxide glass (≥99%) containing some trace metals, but range in diameter from about one to two millimeters depending on the type of paint in which they’re used, according to an email from Steven Loeffler of ODOT’s chemical section.

The glass beads are generally incorporated into the paint, although they can also be applied on top of the paint. Incorporated beads contain a mixture of silane-coated and non-coated beads so that some sink within the paint and some float to the surface, allowing the paint to maintain reflectivity as the sunken beads are exposed with wear (pretty smart, right?). Loeffler says that, depending on paint type, pavement marking paints contain 30%–45% glass beads by weight.

Those glass beads are manufactured by Potter Industries, Weissker, and Swarco Industries, which mainly recycle cullet to produce the beads, says Loeffler.

ODOT’s Steven Loeffler emailed this picture of the glass beads Ohio uses in its pavement marking paints. Credit: ODOT.

ODOT’s records cite $35 million in awarded contracts for pavement markings in 2013, so a lot of money is spent on those innocuous little lines. Many reports from DOTs across the country indicate that number is so high partially because pavement markings need re-applied nearly yearly, although wear does depend on the road surface, traffic volume, and local weather conditions.

For an in-depth review of American pavement marking practices, pros, and cons, read this Purdue University report sponsored by the Indiana Department of Transportation.

Beyond the seemingly more-standard glass beads, some states have also explored ceramic additions to pavement markings.

Vermont’s DOT performed an in-depth evaluation of how ceramic and glass bead mixtures stack up to solely glass beads in 2007. While their tests showed that ceramics offer a five-fold increase in retroreflectivity, the effects don’t last. And because the ceramic-incorporated paints cost substantially more, Vermont didn’t see value in using the paints unless, the report says, “ceramic beads can be protected from winter maintenance practices and other similar abrasion.”

To that end, however, there may be a solution. Montana’s DOT has just begun an experiment (and Minnesota has dabbled, as well) to assess the performance of pavement markings containing both ceramic elements and glass beads incorporated into grooves carved into the road. These efforts may be able to protect the more pricey ceramic-containing paints from wear, particularly from harsh scraping by snowplows. The experiment will be collecting data through 2018, so we’ll have to wait a few years to see how these new methods stack up.

Montana’s ceramic clusters, produced by 3M and composed of a mixture of glass beads with silica, pigment, and a trade secret polymer, claim to improve durability and reflectivity. You can read all about them—and see some great pics—in this pdf from 3M.

Those glowing pavements markings in the Netherlands I mentioned previously offer a solution to a different problem, but are nonetheless pretty impressive (and pretty).

The concept of how glowing pavement markings could improve visibility and safety to drivers. Credit: Studio Roosegaarde.

The brainchild of Dutch designer Daan Roosegaarde, the NY Times reports that the idea behind the project “is that luminescent green road markings painted on the road will make street lighting redundant. This is intended not just to save lighting costs, but also to increase safety by improving visibility on roads that had no lights at all.”

Although the project, called Smart Highway, has been in the works for several years, we are just now beginning to see its application in 500 m of Dutch highway, reports Wired UK.

Although Studio Roosegaarde is pretty mum on the details of the paint’s formulation, they say that “the glow-in-the-dark roads are treated with a special foto-luminising powder,” which they also report can glow for up to ten hours after being charged by a day of sunlight. Watch the Reuters video below to hear more about the project.

We’ll have to wait for more details and test results to see just how smart the road is, particularly in response to a dark overcast day or against wear and tear. The Smart Highway project also has big dreams of interactive road paints that can, for example, alert drivers to icy conditions and a special highway lane that can charge your electronic devices as you drive on it.

Pavement markings—another drummer in our everyday soundtrack.

Video credit: studioroosegaarde on Youtube.