Nanocomposite magnetite–silica and titania nanoparticles loaded on graphene oxide to make a recyclable waste water treatment system. Credit: Gu and Linley; University of Waterloo.

Someone I knew in graduate school liked to say, “You don’t buy coffee and tea—you only rent them.” It was his quirky way of excusing himself to make a quick trip to the “necessary” room.

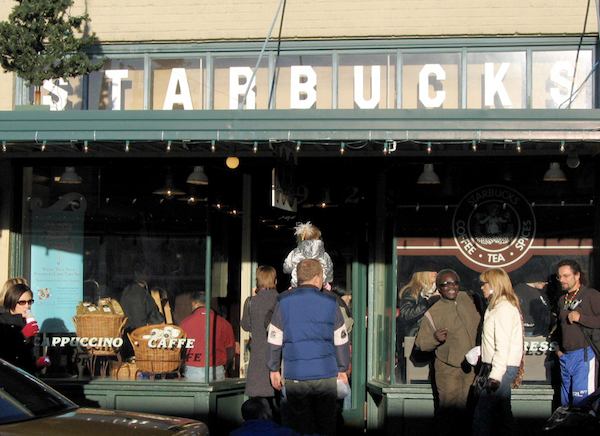

We were in graduate school in the pre-enlightenment era of coffee in the early 1980s. Starbucks was in the embryonic stages (pdf) of morphing from a local Seattle coffeeshop (see featured image) into the every-corner behemoth we know today. (Not complaining, I am a big fan of S’bucks.)

With the growth of enterprises like Starbucks and coffee snobbery/connoisseury in general, there is a lot more caffeine-laden “rent” being paid. Enough for water scientists to measure and take notice.

A 2012 National Geographic article explains that caffeine alone is not the problem—it’s what increased levels of caffeine signify. The article quotes Iowa-based US Geological Survey hyrdrologist Dana Kolpin, “Caffeine is pretty darn ubiquitous, and there is growing evidence that this and other understudied contaminants are out there.” She says, “there is a whole universe of potential contaminants including pharmaceuticals, hormones, personal-care products like detergents or fragrances, even artificial sweeteners.”

As the article says, “In other words, if caffeine’s in the water, chances are there are other contaminants too.”

(There’s long been concern about increased levels of estrogens in drinking water, too, from the waste of women taking birth control pills. However, human waste as a source of estrogenecity was recently shown to be minor compared to other sources, such as animal manure.)

Consequently, water treatment processes for removing caffeine and other contaminants are a lively area of research for water chemists and hydrologists. One approach that is getting a close look is photocatalysis to break down harmful chemical compounds into benign or less-harmful components. Titania’s wide bandgap semiconducting properties make it attractive as a photocatalytic agent, and it has been shown to effectively break down organic compounds. Using a nanoscale form of titania provides essentially 100-percent active surface.

A photocatalyst should be recoverable and reusable for two reasons—efficiency and safety. Using recycled photocatalyst increases cost-effectiveness, and removing nanoscale photocatalysts avoids creating a potential new problem with nanoparticles in treated water.

A new paper in Applied Materials and Interfaces (subscription required) addresses the issue of recyclability. Recyclability involves two challenges: recovering the photocatalyst and treating it with ultraviolet light to “reset” its photocatalytic ability. Clever engineering of ceramic materials allowed the authors to address these challenges.

The research group, led by assistant professor Frank Gu at the University of Waterloo (Canada), had the idea to load a combination of photocatalytic titania nanoparticles and composite magnetic nanoparticles onto graphene oxide (GO) supports to create photocatalytic “modules.” The magnetic nanoparticles are a core–shell structure of magnetite (Fe3O4) surrounded by silica. Adjusting the amount of titania loaded onto the GO meshes—which are nanoscale, also—allowed the team to tune the photocatalytic efficacy. Simultaneously loading magnetic nanocomposites onto the GO meshes allowed them to recover the particle-loaded meshes by exposing the system to a magnetic field.

They tested the system on caffeine and carbamazepine (also a pharmaceutical compound). After testing a few composition ratios, the group found an optimized ratio that performed 1.2 times more effectively than commercial photocatalysts and broke down both organic compounds within 60 minutes.

The modules are also fully recoverable. Photocatalytic activity of the titania can be completely restored by exposing the modules to ultraviolet radiation for 16 hours to remove adsorbed organic contaminants from the surface of the particles.

The paper goes into quite a bit of detail about the synthesis of the magnetic nanocomposites and the chemistry of the photocatalysis, adding that module synthesis should be easily scalable to industrial levels. The authors conclude, “Efficacy on relevant contaminants combined with simple separation after treatment and an efficient, easily controllable modular synthesis technique give the nanocomposite exceptional potential for industrial application of advance water treatment.”

The paper is “Recyclable graphene oxide-supported titanium dioxide photocatalysts with tunable properties,” by Linley et al. (DOI: 10.1021/am4039272).

Featured image: Home of the original Starbuck’s coffeeshop since 1976. Credit: Postdlf from w; Wikimedia.