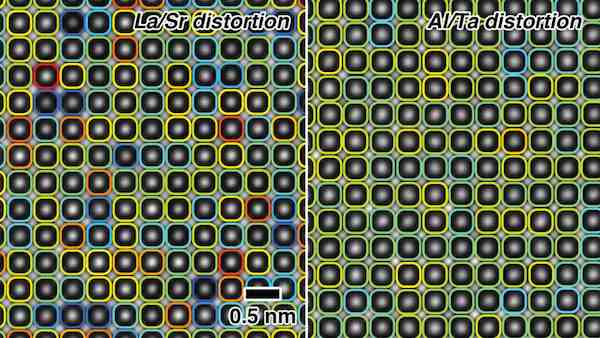

[Image above] Atomic distortion of lanthanum and strontium in LSAT (left). Blue and red indicate contraction and expansion, respectively, of local structure. Aluminum and tantalum sites have a different distortion pattern (right). Credit: J. LeBeau; NC State

Organization is everything—especially when it comes to atoms.

So it’s no surprise that atomic placement within a material is incredibly important for determining material properties and functionality. But pinpointing the specific location of atoms within a material has been hard to achieve.

Now researchers at North Carolina State University have pioneered a new imaging method that allows them to peer into a material’s atomic organization to precisely map the location of distortions, a unique perspective for probing how those tiny variations in crystallographic address affect material properties.

NC State materials science and engineering professors Doug Irving and James LeBeau led the research. LeBeau, an ACerS member, was awarded an NSF Ceramics Program’s 2014 CAREER award, which you may recall was featured in the October/November 2014 issue of the ACerS Bulletin.

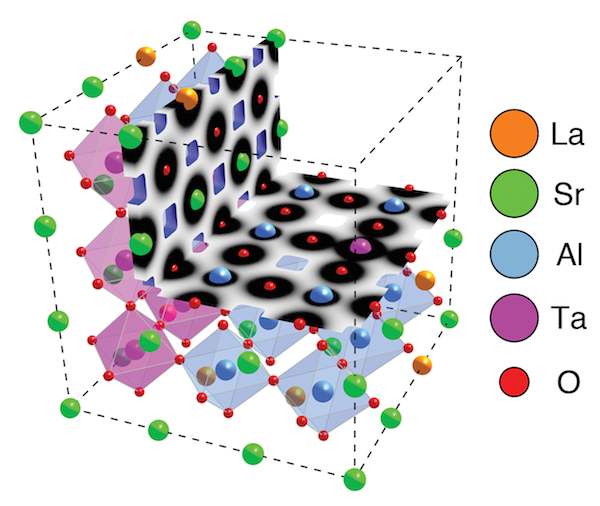

The team of scientists closely examined the placement of atoms within lanthanum strontium aluminum tantalum oxide (LSAT), a hard, optically transparent perovskite structure oxide developed as a ceramic superconductor substrate.

“We knew where the atoms were on average, but we also knew that there were variations in a material—there can be significant displacements, where atoms don’t fit into that average pattern,” says Irving in an NC State press release.

“However, detecting these distortions required indirect methods that could be difficult to interpret, so we couldn’t fully explore how a material’s atomic structure affects its properties,” LeBeau says in the release. “Now we’ve come up with a way to see the distortions directly, at the atomic scale. We can create a precise map of atomic organization, including the distortions, within a material. Not only which atoms fit into the structure, but how far apart they are, and how distortions in the structure are related to the chemistry of the material.”

The scientists used a method pioneered by LeBeau called revolving scanning transmission electron microscopy (STEM) to closely examine the placement of atoms within LSAT.

The revolving STEM technique overcomes distortions caused by drift, or minute sample movement, during nanoscale imaging. By rotating the direction of each scan, the technique can, in the end, eliminate sample drift in scanning TEM and provide a clearer, more accurate picture of the material’s atomic structure. Researchers capture images of distortion from several approaches, which allows them to apply algorithms and remove the drift effect.

With drift effects eliminated, the scientists were able to see complex bonds within LSAT and how outside factors, such as local variations in chemical environment, affected those bonds and led to distortions in the material lattice.

According to the release, “the researchers found that the weaker chemical bonds that hold lanthanum and strontium in place in LSAT’s atomic structure made them more susceptible to being pushed or pulled by small variations in their chemical environment.”

The scientists hope that this unique tool will provide a vantage point that will help them understand—and predict—how atomic organization dictates a material’s properties.

“Now that we can see these subtle distortions, and know what causes them, the next step is to begin work to understand how these structural differences affect specific properties,” LeBeau says in the release. “Ultimately, we hope to use this knowledge to tailor a material’s properties by manipulating these atomic distortions.”

The paper, published in Applied Physics Letters, is “Direct observation of charge mediated lattice distortions in complex oxide solid solutions” (DOI: 10.1063/1.4908124).