[Image above] Credit: Julie Jablonski; Flickr CC BY-NC 2.0

Continuing the topic of the many uses of silicon, perhaps its most elemental achievement is as a basic component of most familiar types of glass.

Glass makes so much of our life possible. But akin to the silica industry, glass also is an energy-intensive industry, one that could use some fresh solutions to reduce its energy consumption.

To that end, researchers and ACerS members from Lehigh University and the University of Colorado have teamed up to decrease the amount of energy needed for glass-forming, during which glass products are formed into their final shapes.

“Electrical heating is widely used in the initial melting process, but not for forming operations, which require glass to be soft and easily deformable, while also keeping the desired shape,” Himanshu Jain, Lehigh University materials science and engineering professor and ACerS member, says in an AIP press release. Jain also directs Lehigh’s International Materials Institute for New Functionality in Glass (IMI-NFG).

[In related news, researchers at the University of Wyoming recently showed than an electric field also can influence the fracture toughness of nanomaterials.]

According to the AIP release, Jain teamed up with fellow ACerS member and newly inducted Distinguished Life Member Rishi Raj after hearing him speak at the 2011 Synthesis and Processing Science Principal Investigators’ Meeting (pdf) in Arlington, Va. The U.S. Department of Energy’s Office of Basic Energy Sciences Program sponsored the meeting.

At the meeting, Raj presented his work on using electrical fields to decrease the sintering temperature of ceramic powders—which made Jain wonder if the same technique could work for glass, too. “I was intrigued by his lecture, which led to discussion during the break and plans to pursue it subsequently,” Jain explains in an email.

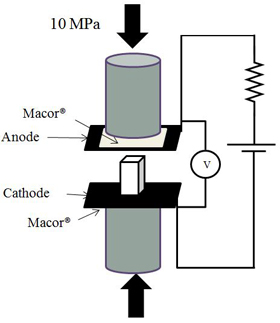

Back in the lab, the scientists—including Lehigh researchers and ACerS members Charles McLaren and William Heffner, and University of Colorado researcher Riccardo Tessarollo—used a modified pneumatic creep tester to heat alkali silicate glass blocks under compression (with a 10 MPa load) to see how varying the heating method affected deformation. Compressive force deforms glass, providing clear visual evidence of how different heating conditions affect the ability to shape-form glass.

The modified pneumatic creep tester. Credit: Himanshu Jain; AIP

The team tested sodium silicate and lithium-sodium silicate glasses of varying compositions, “with fixed mole percentage of the alkali ions such that the mobility of alkali ions is greatly reduced while the basic network structure does not change much”—i.e., varying electrical resistances—according to the paper’s abstract.

Comparing measurements of deformation of the glass when heated with a furnace alone or with the addition of an electric field revealed something that can be rare in research—the anticipated result.

Just like with the ceramic powders Raj had tested, adding an electric field lowered the temperature required to shape-form glass, indicating the potential for energy savings in this process.

Charles McLaren uses an electric field to induce the softening of glass. Credit: Lehigh University

The temperature change depended on glass composition and strength of the applied electric field, with a stronger field more significantly lowering the temperature required to deform glass.

Sodium silicate glass showed the biggest change in glass-forming temperature with applied electric field, reaching a maximum measured difference of about 150°C with a 200 W/cm electric field, according to the published paper.

But how much energy savings could the technique offer? “Quantification is rather tricky depending on the furnace size, forming process, etc.,” Jain says in the email.

According to him, however, there’s more to the new technique. “It appears that besides the energy savings, the results may be exploited to form micro- and nano-features in glass more precisely, because electric fields can be applied with much greater precision than mechanical force alone,” Jain says in the email.

According to the AIP release, the team is continuing its work by testing a broader variety of glasses to determine specific compositions that differently influence electric-field-induced softening.

“Gaining a better understanding of the underlying phenomenon will help us learn the limitations of glass as an electrical insulator,” Jain adds in the release. “There’s tremendous interest in using glass as a supercapacitor for energy storage, for example. But it’s critical not to use glass that deforms easily in such applications, so it would be helpful to know in advance how the glass will behave.”

The paper, published in Applied Physics Letters, is “Electric field-induced softening of alkali silicate glasses” (DOI: 10.1063/1.4934945).