[Image above] Local Motors’ new 3-D-printed car, the LM3D Swim. Credit: Local Motors

Last fall, Local Motors unveiled the world’s first 3-D printed car, Strati, with a flourish: The company not only unveiled the first 3-D printed car, it live-printed the Strati during the automotive industry’s huge Specialty Equipment Market Association (SEMA) show.

While Strati was a prototype, Local Motors has taken the concept one giant leap further—at this year’s SEMA show earlier this month, Local Motors debuted the LM3D Swim, its first attempt to enter 3-D printed cars into the mass production market.

LM3D Swim will be the first in the company’s LM3D series of 3-D printed vehicles, which Local Motors plans on releasing throughout 2016.

According to the company’s website, “Taking just over two months from design to prototype, Local Motors built a 3-D-printed car at unprecedented speed.”

Talk about fast—watch the printing in high-speed action in this short video from Local Motors.

Credit: localmotors; YouTube

Part of the reason Local Motors can drive production so quickly is the capabilities of 3-D printing, or additive manufacturing, which the company is relying upon to produce its disruptive vehicles. Additive manufacturing itself has come a long way in the past few years. More materials than ever can now be 3-D printed, and advanced resources have allowed additive manufacturing to streamline production of even complex prototypes (including robots).

The LM3D Swim is composed of ~75% 3-D-printed parts, although Local Motors hopes to eventually bump that percentage up to 90%. That last little bit will account for “traditional” auto parts that the company isn’t planning on trying to 3-D print, including wheels, tires, drivetrain, and steering components.

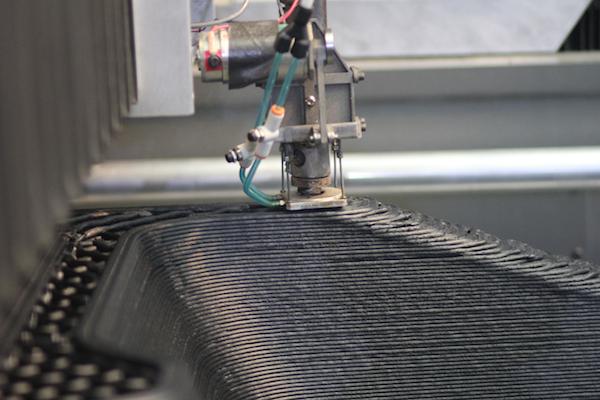

3-D printed parts will be made of Local Motors’ tested material composition of 80% thermoplastic polymer (acrylonitrile butadiene styrene, or ABS) and 20% carbon fiber.

Local Motors says it is continuing to explore new materials, however, including a flexible rubber-like printable polyurethane and thermoplastic elastomer called NinjaFlex. (Watch NinjaFlex’s indestructibility here.)

One of the deciding factors for its choice of materials is Local Motors’ commitment to making auto manufacturing smarter, simpler, and more sustainable. According to the company’s website, “Post-production vehicle emissions are only half of the equation. Sustainable vehicle development utilizing direct digital manufacturing techniques, at small-footprint microfactories, separates Local Motors from the competition.”

Another alliterative attribute that Local Motors is trying to add to its list of smart, safe, and sustainable is to also make its 3-D printed cars safe.

The company’s next step for its LM3D cars is to earn them a thumbs-up from federal crash tests and highway certifications. The company says that early tests indicate that it will be finished with crash testing—and have its 3-D printed cars ready for the road—by the end of 2016. “In fact, our goal is to make 3D-printed cars safer than traditionally manufactured cars,” Local Motors says on its website.

Unlike Strati, which was printed in one build on Cincinnati Incorporated’s huge Big Area Additive Manufacturing (BAAM) machine—which also helped print a beautiful homage to the Shelby Cobra—the LM3D series will be printed as multiple parts to increase the cars’ safety and allow easier repairs, upgrades, and customization.

That means that Local Motors can bypass the BAAM and rely on not-quite-as-large large-scale printers in its own microfactories, which exist in Phoenix, Ariz.; Las Vegas, Nev.; and Crystal City, Va. The company is adding another microfactory in Knoxville, Tenn., next year that will solely focus on its 3-D printed cars.

Local Motors says that each microfactory can accommodate up to six large-scale printers, and the company is expecting that its capacity will reach 2,400 3-D-printed cars per year.

LM3D vehicles are expected to enter into the crowdfunding world of Indiegogo in the second quarter of 2016, according to Local Motors. Retail sales—at an expected MSRP of $53,000—are expected to start in late 2016.