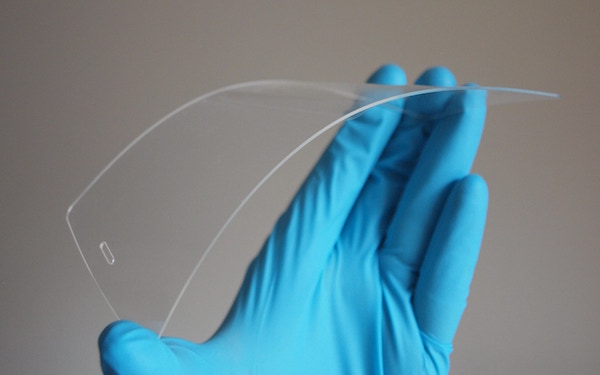

[Image above] Credit: University of Sussex

Researchers at the University of Sussex (Brighton, U.K.) have unveiled a new touchscreen material that offers several improvements over the industry standard, indium tin oxide, and could enable less breakable future smartphone screens.

The material, a layered combination of silver nanowires and graphene, is more inexpensive, flexible, and robust than indium tin oxide—which altogether could enable smartphone screens that aren’t composed entirely of glass.

Indium tin oxide is a transparent and conductive material, making it well suited for touchscreen technology. But the little problem with indium tin oxide is the indium—a rare earth that’s scare in supply and consequently high in cost. So researchers and manufacturers have been searching for a replacement material.

Graphene has been a viable option, although it’s not perfect. Several other materials have been considered and investigated as well, including carbon nanotubes, silver nanowires, and gallium-doped zinc oxide—but so far, none of the options have been just right.

Now, a team of researchers at the University of Sussex may have developed a Goldilocks touchscreen material that is just right—a combination of silver nanowires and graphene.

To fabricate the new touchscreen, the team patterned graphene on top of a film of silver nanowires. In a method similar to using a potato stamp, the researchers used a polydimethylsiloxane (a simple silicone polymer) stamp to grab a single layer of graphene floating on the surface of water and transfer it on top of a silver nanowire film.

The graphene layer serves several purposes—for one, it protects the silver nanowires from tarnishing. But graphene also links the silver nanowires together, according to an IEEE Spectrum article, and and boosts their electrical conductivity, allowing just a small amount of silver to be sufficient for the touchscreen. The resulting layered material, which has considerably lower cost than indium tin oxide, is flexible and maintains its electrical properties even after repeated bending.

“The addition of graphene to the silver nanowire network also increases its ability to conduct electricity by around a factor of ten thousand,” Alan Dalton, Sussex professor of experimental physics and senior author of the research, says in a University of Sussex press release. “This means we can use a fraction of the amount of silver to get the same, or better, performance. As a result, screens will be more responsive and use less power.”

In addition to enhanced performance and reduced cost, the touchscreens could enable entire smartphone screens that are less likely to break as well. Because the silver nanowire touchscreen is more robust, it could allow smartphone manufacturers to reduce the glass substrate of smartphone screens—which support the thin touchscreen material—to a thin layer.

“What we are envisaging is that the typical glass top surface of the device would be replaced by plastic with a thin, scratch-resistant glass protective layer,” Matt Large, first author and lead researcher on the project, explains via email. “The whole device would then be far more robust as the thinner glass and plastic could flex to absorb impact energy when dropped. Even if the glass layer does get cracked, it would be far cheaper to peel off and replace than having to replace the whole touch sensor.”

Large also adds that the new touchscreen can be deposited on top of glass, too.

Plus, the new touchscreen material seems to have major commercial potential when it comes to manufacturing as well. In addition to lower material costs than indium tin oxide, the fabrication technique is scalable, too.

“It would be relatively simple to combine silver nanowires and graphene in this way on a large scale using spraying machines and patterned rollers,” Dalton adds in the release.

The paper, published in Langmuir, is “Selective mechanical transfer deposition of Langmuir graphene films for high-performance silver nanowire hybrid electrodes” (DOI: 10.1021/acs.langmuir.7b02799).

Another paper detailing the team’s finite-size scaling theory behind the silver nanowire films, published in Nanoscale, is “Finite-size scaling in silver nanowire films: design considerations for practical devices” (DOI: 10.1039/C6NR03960J).

Did you find this article interesting? Subscribe to the Ceramic Tech Today newsletter to continue to read more articles about the latest news in the ceramic and glass industry! Visit this link to get started.