[Image above] Credit: Lisa Williams; Flickr CC BY 2.0

Credit: Michigan Engineering; YouTube

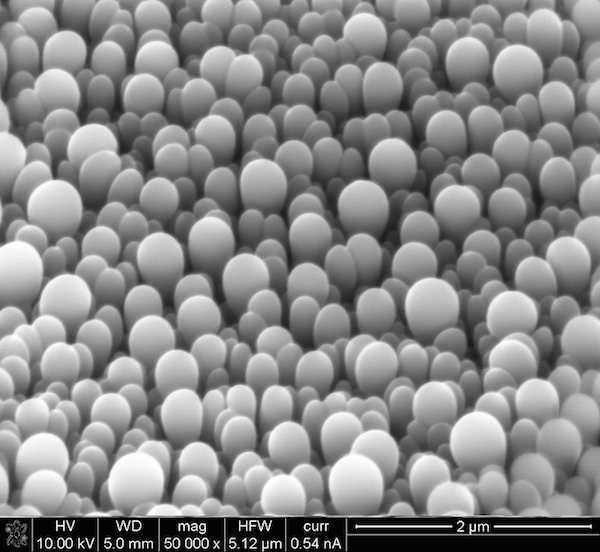

When you think of a crystal, chances are that straight edges and sharp corners come to mind. But researchers from the University of Michigan have figured out how to craft rounded crystals that resemble the bumpy surface of starfish shells.

The scientists fashioned nanolobes—which they say resemble mini hot air balloons—of boron subphthalocyanine chloride crystals quite by accident, according a Michigan press release.

They were creating thin films of the material using organic vapor jet printing, a technology akin to spray painting that replaces paint with gas, according to the release.

But while adjusting the machine, they noticed that films thicker than 600 nm developed a wonky structure.

“At first, we wondered if our apparatus was functioning properly,” senior researcher Max Shtein says in the release.

X-ray analyses revealed that the films were covered with nanolobes of boron subphthalocyanine chloride crystals, which normally do not form ordered structures.

And it wasn’t an anomaly—tinkering with the machine a bit more, the researchers found that films thicker than 800 nm reliably produced the structures.

“In my years of working with these kinds of materials, I’ve never seen shapes that looked like these. They’re reminiscent of what you get from biological processes,” Shtein says. “Nature can sometimes produce crystals that are smooth, but engineers haven’t been able to do it reliably.”

The researchers are hopeful the tech can be applied to fabrication techniques to print advanced LEDs, solar cells, and functional surfaces. They’re also hopeful for applications in another lucrative industry—pharmaceuticals. Printing with the method could manufacture surface area-rich pills for economical quick-release medications.

The paper, published in Nature Communications, is “Growth and modelling of spherical crystalline morphologies of molecular materials” (DOI: 10.1038/ncomms6204).