Ceramics Expo 2022, which occurred in-person this year from August 30–31, welcomed dozens of exhibitors and hundreds of attendees to Cleveland, Ohio. Learn about what took place during the two-day event.

Read MoreFlash-sintering of ceramics can lead to microstructural heterogeneity, which can negatively impact the material’s performance. Researchers in Brazil demonstrated that forming method can influence the final microstructure of flash-sintered ceramics.

Read MoreWhile India does well in research and development of semiconductor chips, the country has few semiconductor fabrication plants and none are for commercial use. In recent months, the Indian government laid the groundwork to bring commercial chip manufacturing to India.

Read MoreCurrently, replacing conventional materials with carbon fiber-reinforced polymers typically increases life cycle energy use due to the energy-intensive fiber production process. A new prospective life cycle assessment suggests certain technological developments could lead to carbon fiber composites with lower environmental impact than glass fiber composites.

Read MoreRemoval of ammonium ions from semiconductor wastewater is a particular concern for chip manufacturers to avoid exacerbating eutrophication of aquatic environments. Researchers in South Korea investigated the potential of graphene oxide-based nanofiltration membranes to treat this type of wastewater.

Read MoreSemiconductor chip manufacturer Intel announced it is committing $20 billion to build a manufacturing mega-site on the outskirts of Columbus, Ohio. Learn about some of the big events that have affected the semiconductor industry in recent years and how Intel’s announcement fits into the narrative.

Read MoreThe ability to count the number of active sites on oxide catalysts and thereby determine the reaction turnover frequency has developed very slowly in comparison to metal catalysts. In a recent paper, Lehigh University professor Israel E. Wachs argues for further developing the methodology of methanol chemisorption to address this situation.

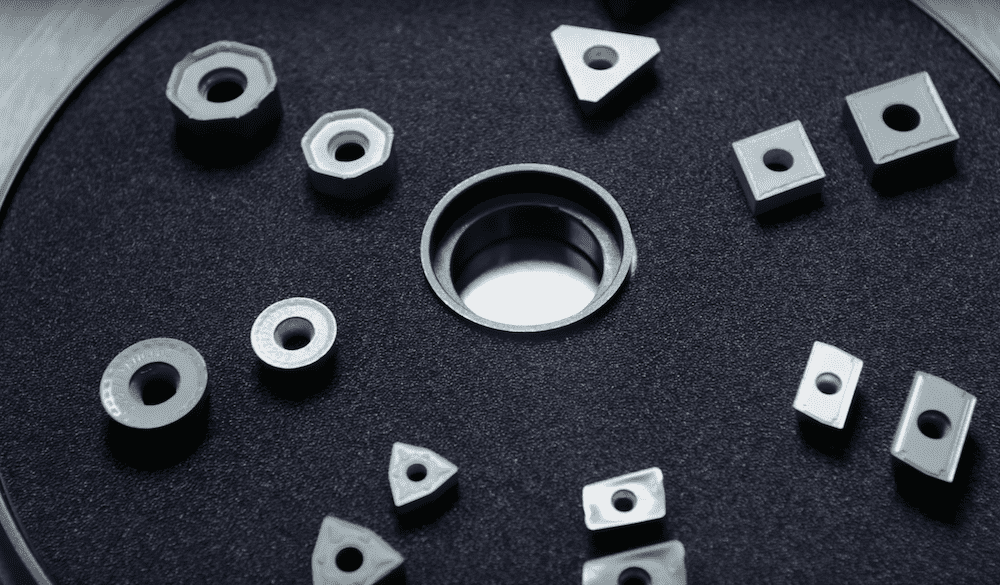

Read MoreCobalt is a main material used as the binder in cemented carbides, but there are drawbacks to using this metal. Ceramic phases have started attracting significant attention as alternative binders, and a recent study dives further into the feasibility of using nanoceramics as a binder.

Read MoreSteel plates are the typical material used to join refractory ceramics in rotary kilns, but certain conditions can lead the steel to deteriorate and cause catastrophic wear. Researchers in Japan explored whether a basic mortar could be used instead of steel plates.

Read More