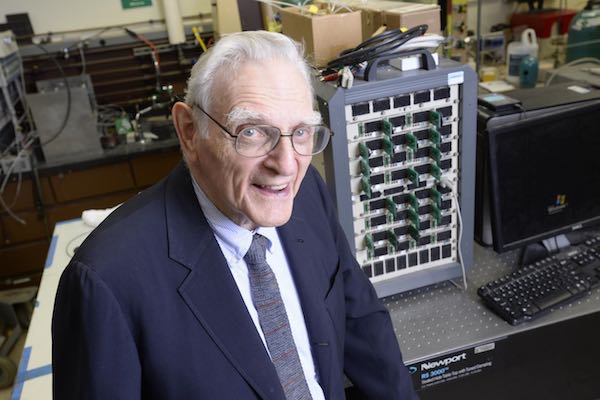

[Image above] Battery guru John Goodenough. Credit: University of Texas at Austin

Lithium-ion batteries have revolutionized our modern world—but we still need something better to power our demanding energy storage needs into the future.

That’s because, despite all their merits, lithium-ions have a few key problems. One is that although lithium is relatively abundant on Earth, its availability and supply chains aren’t sufficiently stable—which means that lithium is not the cheapest resource we could utilize. Elementally speaking, there are better choices.

And, as the world well knows, lithium-ions have some serious safety issues.

Not to mention that lithium-ions are approaching their limits in terms of performance. Some scientists estimate that improvements can only increase the energy capacity by weight of lithium-ions by up to 30%.

Even lithium-ion battery coinventor John Goodenough agrees that lithium-ions are no longer good enough.

Along with a team of researchers at the University of Texas at Austin, Goodenough is trying to revolutionize the battery world yet again with a new and improved all-solid-state sodium-ion battery. The team says their battery has three times higher energy density than today’s lithium-ion batteries, making it inexpensive, safe, and long-lasting enough to completely change the market for electric vehicles and much more.

And who better to lead a battery revolution than a 94-year-old battery research veteran?

“Cost, safety, energy density, rates of charge, and discharge and cycle life are critical for battery-driven cars to be more widely adopted,” Goodenough says in a University of Texas at Austin press release. “We believe our discovery solves many of the problems that are inherent in today’s batteries.”

Solid-state batteries swap the liquid electrolyte for a solid one, which solves the batteries’ combustion concerns. When it comes to solid electrolytes, ceramics often are the materials of choice (for example, see here, here, and here).

So why aren’t we already using solid-state batteries?

While much safer, ceramic electrolytes come with challenges for developing solid-state batteries. “A large interface resistance and severe dendrite formation across an alkali-metal/ceramic interface are two critical factors that have restricted the application of ceramic electrolytes in all-solid-state batteries,” the authors write in an ACS Central Science paper describing their new research.

But the UT Austin team’s research shows that a simple glassy interlayer between cathode and electrolyte can increase battery stability and boost its performance by solving the problem of dendrite formation.

To create the glassy layer, the scientists simply heated thin pellets of their ceramic electrolyte (Na3Zr2Si2PO12) with sodium metal to form at thin, amorphous layer on top of the ceramic.

The team’s experiments with a ceramic electrolyte without the protective interlayer showed that dendrites quickly develop, which penetrate grain boundaries and short-circuit the battery.

But the presence of a thin glassy layer prevented dendrite formation, allowing the battery to operate efficiently for more than 1,200 cycles.

Goodenough has promoted the promise of sodium-ion batteries before, partially because sodium-based batteries alleviate the cost and elemental availability concerns that come with lithium-ions. Sodium is abundantly and easily available, even from sources such as seawater.

So by combining low cost and improved performance, the UT Austin team’s solid-state sodium-ion battery has real potential to bump the lithium-ion from its top spot—eventually.

The team has patented the electrolyte technology and continues to develop the research, according to the press release. “The UT Austin Office of Technology Commercialization is actively negotiating license agreements with multiple companies engaged in a variety of battery-related industry segments.”

The paper, published in ACS Central Science, is “Rechargeable sodium all-solid-state battery” (DOI: 10.1021/acscentsci.6b00321).