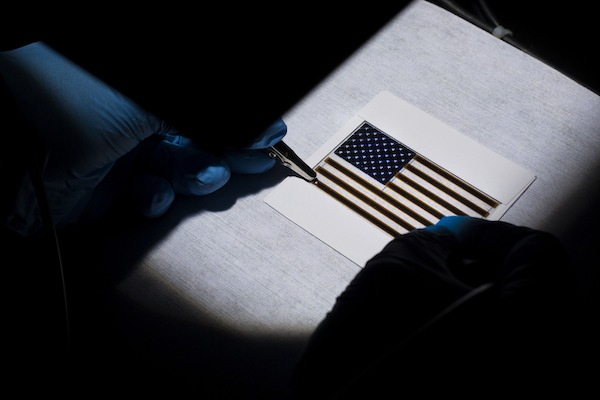

Researchers from the University of Michigan have developed aesthetically-pleasing solar cells. Credit: Michigan Engineering; You Tube.

Researchers from the University of Michigan have a new idea for solar cells—make them pretty. Led by Jay Guo, professor of electrical engineering and computer science, mechanical engineering, and macromolecular science and engineering, the scientists have created thin semitransparent solar cells that can be fabricated with an array of colors and designs. Watch the video above to get Guo’s take on the technology.

“I think this offers a very different way of utilizing solar technology rather than concentrating it in a small area,” Guo said in University of Michigan press release. “Today, solar panels are black and the only place you can put them on a building is the rooftop. And the rooftop of a typical high-rise is so tiny.”

Conventional solar cells are black to absorb the most solar energy, but Guo’s new cells sidestepped the drab. The team created thin solar cells that allowed light to pass through and added colored designs to up the aesthetic factor.

Even though their pretty solar cells absorb less energy, the makeover allowed them to break free from rooftop confinement. The new cells look so nice that putting them in view is no longer a problem. They can be applied to windows, for instance—and windows have a lot of surface area, particularly on tall buildings.

The paper, recently published in Scientific Reports, details how the scientists created their new solar cells with a thin sheet of amorphous silicon sandwiched between semi-transparent electrodes, one of which is made from an organic material. The organic-inorganic hybrid design allowed fabrication of cells ten times thinner than traditional amorphous silicon solar cells, according to the press release.

With the freedom of thin, semi-transparent cells, the scientists then added the aesthetics—they fabricated designs on the cells with reflective layers, including the University of Michigan logo and an American flag. “To get different colors, they varied the thickness of the semiconductor layer of amorphous silicon in the cells,” states the press release. “The blue regions are six nanometers thick while the red is 31 (the team also made green, but that color isn’t in the flag).”

The cells achieved just 2% efficiency, in comparison to the ~10% achieved in standard organic solar cells. But what they lack in functionality, they make up for in looks. Guo said in the press release that a square-meter panel still generates enough electricity to light a fluorescent bulb or small electronics. And the increase in potential surface applications means that sheer surface area can make up for lower efficiency.

The paper is “Decorative Power Generating Panels Creating Angle Insensitive Transmissive Colors” (DOI: 10.1038/srep04192).

And in other solar cell news, German scientists at Kiel University and Helmholtz-Zentrum Geesthacht have developed a film that may protect the surfaces of solar cells. Those surfaces are vulnerable to degradation from long-term exposure to UV light—ironic, huh?

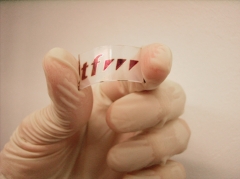

The UV-absorber (shown here with the logo of Kiel University’s Faculty of Engineering) is even applicable on flexible materials. Credit: D. Schimmelpfennig/CAU.

The study, published in Applied Physics Letters, details how the scientists developed an ultrathin UV light-absorbing film made from a plasmonic metamaterial (pictured, right). The film, only 20 nm thick, completely absorbs UV light. Most solar cells collect energy from light in the visible or infared regions of the light spectrum.

The researchers used cosputtering to fabricate films with three layers—a top nanocomposite layer containing silver nanoparticles in silicon dioxide and two layers of silicon dioxide with a silver film. The film absorbs UV-A light through reflectivity of the bottom silver layer.

“Since our perfect absorber can be deposited on even flexible substrates, we envision that this structure can be potentially used also in thin film solar panels, which are intended to be used in next generation clothing industry”, first author Mehdi Keshavarz Hedayati said in the press release.

The paper is “Plasmonic Tunable Metamaterial Absorber as Ultraviolet Protection Film”(DOI: 10.1063/1.4863202).

Feature image credit: Joseph Xu, Michigan Engineering Communications & Marketing.