The idea of using fibers, wires or some other protruding structures to provide a three-dimensional surface for enhancing the energy-capturing capabilities of photovoltaic units seems to be catching on. The most recent announcement comes from the California Institute of Technology where a team of researchers has successfully used tiny silicon wires contained in a flexible polymer substrate.

The idea, of course, is to capture more light – and therefore more light energy – by increasing the surface area beyond what can be done with the more familiar two-dimensional PV panels. A similar concept is being worked on by a Georgia Tech group.

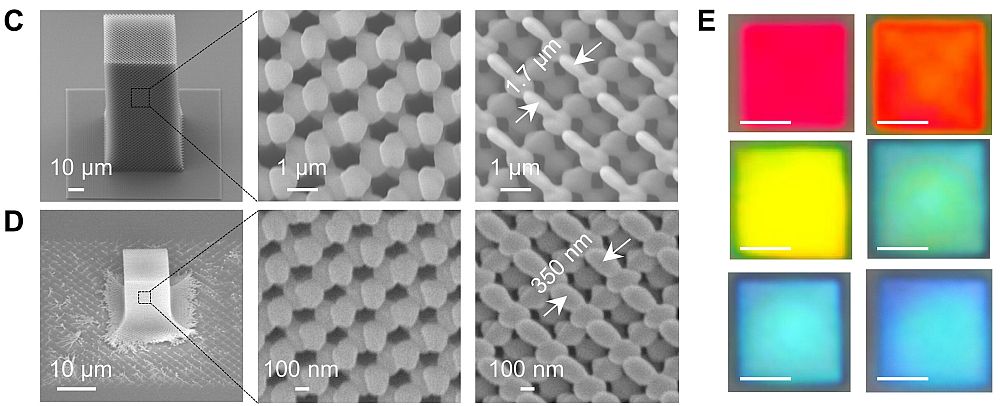

The Caltech group’s silicon wires are 30 and 100 microns long and about 1 micron in diameter, and each has been given an antireflective coating. Besides the wires, light scattering particles are also seeded in the polymer. Essentially, instead of a flat, brittle silicon wafer, the researchers have put the photoreactive silicon into the wires. The end result is a type of film that is highly efficient at absorbing sunlight and turning it into a useful energy source.

“These solar cells have, for the first time, surpassed the conventional light-trapping limit for absorbing materials,” says Harry Atwater, a Caltech professor and coauthor of a paper that appears in Nature Materials. “Many materials can absorb light quite well but not generate electricity — like, for instance, black paint. What’s most important in a solar cell is whether that absorption leads to the creation of charge carriers.”

Atwater, who is the director of Caltech’s Resnick Institute, and others working on this project have been tinkering with how densely packed the wires must be in the polymer and how much of the scattering particles to use. It turns out that they are so efficient that they don’t have be very dense at all to be effective. The wires take up only 2%-10% of the polyester–wire arrays.

But, Atwater says their arrays can absorb up to 96% of incident sunlight at a single wavelength and 85% of total collectible sunlight, converting 90%-100% of the photons they absorb into electrons. “We’ve surpassed previous optical microstructures developed to trap light,” he says. “High absorption plus good conversion makes for a high-quality solar cell,” says Atwater. “It’s an important advance.”

According to these researchers, there are two major cost-saving implications of their work. First, their arrays can produce an equivalent amount of energy using one-fiftieth the amount of silicon. Second, these arrays can be manufactured in roll-to-roll processing, a method that is more efficient than making individual PV panels.

Volume manufacturing, however, isn’t just around the corner. “The structures we’ve made are square centimeters in size,” he explains. “We’re now scaling up to make cells that will be hundreds of square centimeters—the size of a normal cell.”

CTT Categories

- Energy

- Material Innovations

- Optics