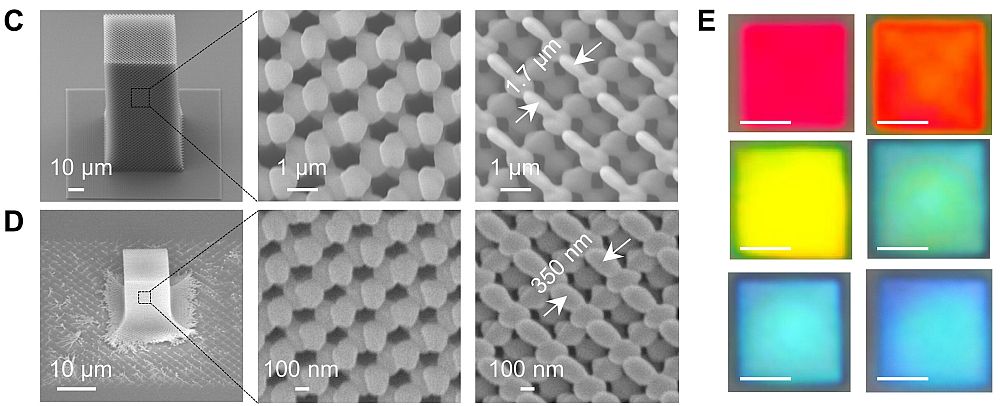

[Image above] Micrograph of one strand of a new spray-on super-nanotube composite developed by the National Institute of Standards and Technology (NIST) and Kansas State University. A ceramic shell surrounds the multiwall nanotube core. The composite is a promising coating for laser power detectors. (Color added for clarity.) Credit: Kansas State University.

How does one measure the optical power output of lasers that are able to—and even designed to—destroy materials? Some lasers with optical output that high are built to be weapons; others are used for friendlier purposes like defusing unexploded landmines.

Designing a power detector that can capture and measure very high laser power without vaporizing away is one application of a new coating developed by researchers at Kansas State University and NIST. The team, led by Gurpreet Singh at KSU published results on a new carbon nanotube-ceramic composite coating in ACS Applied Materials and Interfaces, in their recent article, “Very high laser-damage threshold of polymer-derived Si(B)CN-carbon nanotube composite coatings.”

According to a NIST press release, NIST has been coating optical detectors with carbon nanotubes because their intense black color maximizes light absorption. This new coating comprises multiwall carbon nanotubes (MWCNT) encased in an amorphous SiBCN shell, as shown in the image above. Adding boron increases the refractoriness of the coating.

The KSU team developed the composite with an assist from the NIST researchers who suggested using toluene for both the preceramic polymer solvent and for the MWCNT dispersant. Singh explained in an email, “Toluene-CNT dispersions were more stable and homogeneous [than dispersions based on] chloroform, acetone, or water.” The NWCNTs are dispersed in toluene into which preceramic polymer is added. When the solution is heated to 1,100°C, an amorphous SiBCN shell forms over the MWCNTs. The composite is ground into a fine powder, dispersed in toluene, and sprayed onto copper substrates.

The optical power meter works by absorbing the high-intensity laser light on its inside surface, which is typically a copper cone calorimeter coated with a black absorbing material (for example, the new MWCNT-ceramic coating). It absorbs the incident light and converts it to heat. The heat transfers to water flowing behind the copper heat sink. By precisely measuring the water flow and temperature increase, the energy absorbed can be calculated. (See schematic of device.)

The optical power meter works by absorbing the high-intensity laser light on its inside surface, which is typically a copper cone calorimeter coated with a black absorbing material (for example, the new MWCNT-ceramic coating). It absorbs the incident light and converts it to heat. The heat transfers to water flowing behind the copper heat sink. By precisely measuring the water flow and temperature increase, the energy absorbed can be calculated. (See schematic of device.)

To test the efficacy of the composite coating, the team subjected it to 10.6-micrometer wavelength irradiation from a 2.5 kW CO2 laser. The composite coating outperformed other tested materials-MWCNT, single wall CNT, and carbon paint- by an order of magnitude or more. According to the paper’s abstract, the damage threshold for the composite coating was 15 kWcm-2 with an optical absorbance of 97 percent. Essentially, the coating absorbed all of the light.

In contrast, the MWCNT-only coating exhibited damage at 1.4 kWcm-2 with 76 percent absorbance. SWCNT broke down at 0.8 kWcm-2 and only 65 percent absorbance, and damage started in the carbon paint coating at 0.1 kWcm-2 and 87 percent absorbance.

According to the press release, the MWCNT component absorbs the irradiation and transmits the heat, while the ceramic shell provides oxidation and damage resistance. Apparently, though, under the right conditions, the outer shell oxidizes partially to form an external silica layer, which can be used to tune the coating depending on the application.

Singh said there are other possible applications for the MWCNT-ceramic coating, such as lithium-ion cycling. They are also looking into applications such as nanostructured coatings for protection in extreme environments like rocket nozzles.

This last application reminded me of an interview I did several years ago with NASA Space Shuttle astronaut, Danny Olivas. Olivas is a metallurgist and was very involved in the materials aspects of the failure analysis after Columbia disintegrated in 2003. In the aftermath, he also led the effort to develop an in-flight repair kit to mitigate damage to the heat shield tiles. (It was determined that a breach of the heat shield contributed to the Columbia tragedy.) The team developed a similar material: a preceramic polymer that fired to silicon carbide. The idea was that the polymer would be “painted” onto the damaged area and would fire, literally, using the reentry atmosphere itself as the “furnace.”

To the best of my knowledge, the system was never used (thankfully). The Shuttle program ended in 2011, so we will never know whether it would have worked.

Author

Eileen De Guire

CTT Categories

- Nanomaterials

- Optics

- Thermal management