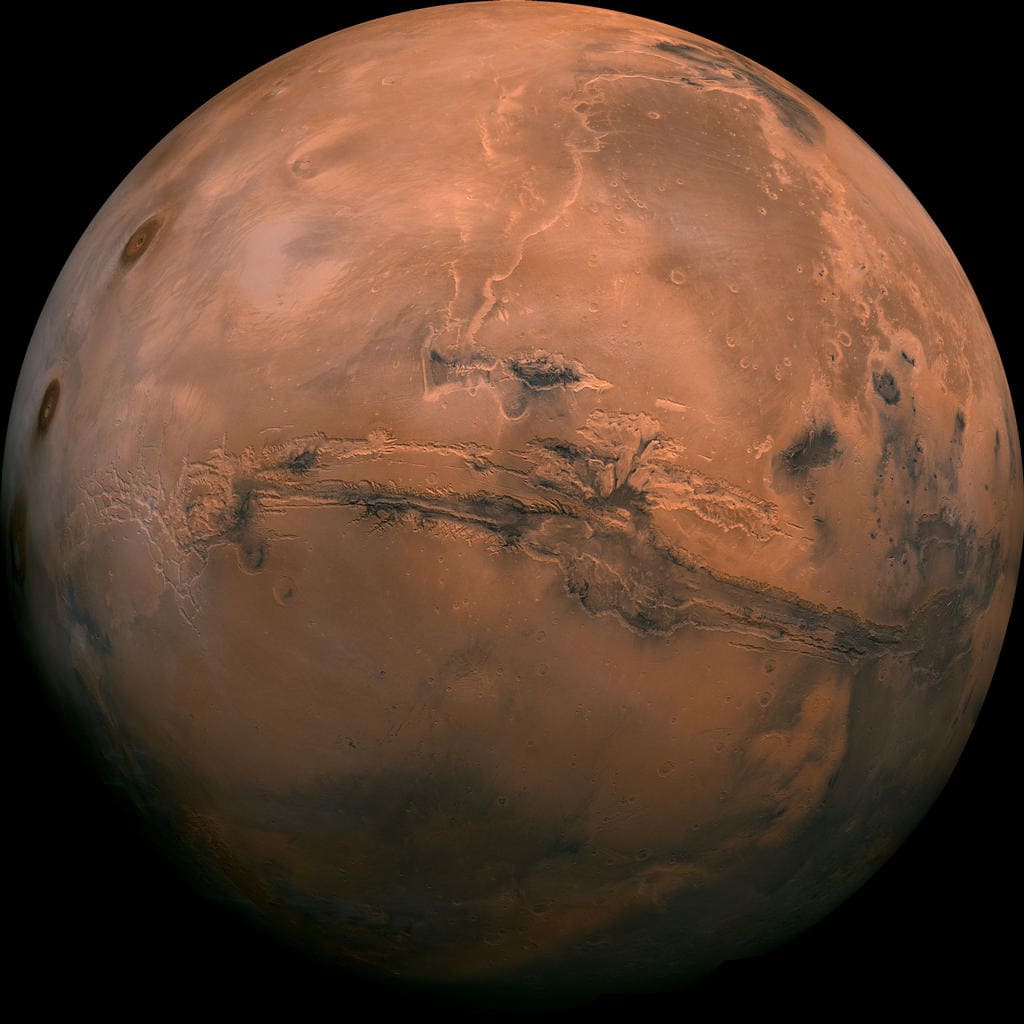

[Image above] Mars; global view of Valles Marineris. Credit: NASA/JPL-Caltech

The ductility and durability of ancient concrete was an engineering feat that still holds true today. Just look at structures like the Pantheon and Colosseum in Rome that are still standing. Concrete has helped shape and advance human civilizations for thousands of years.

Since ancient Roman times, advances in concrete have shifted to serve more modern needs, like permeable concrete that allows thousands of liters of water to flow right through its surface to prevent pooling and puddles.

As engineers continue to evolve modern concrete here on Earth, some materials scientists have taken their concrete visions to outer limits.

The gap between the dream of sending a manned mission to Mars and the reality of actually accomplishing such an achievement is getting remarkably smaller, and space agencies across the globe are hyper-focused on solving the numerous problems this journey would present for human travelers. One of the major hurdles is how to protect humans once they reach the red planet.

Because if we’re going to colonize Mars someday, we’ll need durable structures capable of sheltering us from the harsh Martian elements.

Enter: Martian concrete.

Materials scientist Lin Wan and her colleagues at Northwestern University’s Center for Sustainable Engineering of Geological and Infrastructure Materials (SEGIM) in Evanston, Ill., have developed a method for making Martian concrete using materials that are available in generous supply on Mars and without using water—a resource that will be limited and precious on the planet.

The starring element in waterless Martian concrete is sulfur. The team explains in their open-access paper that Mars has long been considered a sulfur-rich planet, so they developed new construction materials composed largely of simulated Martian soil and molten sulfur that compares in strength to conventional cement-like concrete on Earth—but it’s highly anticorrosive and completely recyclable.

“Its [sulfur] strength reaches similar levels to conventional cementitious concrete, fast curing, low temperature sustainability, acid and salt environment resistance, and 100% recyclability are appealing superior characteristics of the developed Martian concrete,” the authors explain in the paper’s abstract.

The team heats the sulfur until it reaches 240°C and is liquefied, then mix it with aggregate—simulated Martian soil—and let the mixture cool. As the sulfur solidifies, it binds the soil and hardens the material to make concrete.

Through compression testing, the team found that Martian concrete reached a compressive strength of 50 MPa or more, thanks to the strong chemical bonds sulphur makes with the Martian soil during curing. That’s compared to standard concrete used in buildings on Earth that have a compressive strength of about 20 MPa, the authors explain.

Martian concrete cube specimen (a) before and (b) after unconfined compression test. Credit: Wan et al., Northwestern University

And that improved compressive strength will be necessary on Mars, since the planet’s atmospheric pressure and temperature range so widely compared to Earth’s more hospitable conditions.

The potential to make concrete on Mars without having to ship raw materials by space shuttle from home base means that creating structures on site might be easier, cheaper, and more straightforward than ever imagined.

Suddenly, the idea that generations of humans in the not-too-distant future will live, work, and play on Martian soil doesn’t seem so far-fetched.

The open-access paper, available on the preprint server arXiv, is “A novel material for in situ construction on Mars: Experiments and numerical simulations.”

Author

Stephanie Liverani

CTT Categories

- Aeronautics & Space

- Cement

- Construction

- Material Innovations

Related Posts

The urban fabric of brick—Part 3: Innovations and the future of design

November 11, 2025

The urban fabric of brick—Part 2: Ancient brick history

October 28, 2025