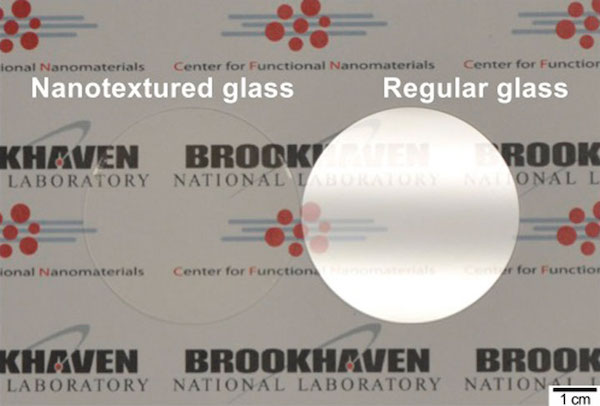

[Image above] Glass surfaces with etched nanotextures reflect so little light that they become essentially invisible. This effect is seen in the above image, which compares glare from a conventional piece of glass (right) to that from nanotextured glass (left). Credit: Brookhaven National Laboratory

Screen glare is a big problem with windows, TV screens, smartphones, and computer screens. We’ve put up with it all our lives and eventually accepted this little annoyance.

In fact, an entire industry has sprung up around this problem. A quick internet search on “how to fix glare on TV screens” yields more than two million results, including several how-to videos and dozens of products for sale.

Although it may seem like a first-world problem, glare and glass surface reflection is a factor that affects the efficiency of solar panels. And for an industry that has experienced an annual growth rate of 68% in the past decade, efficiency is an important consideration.

There’s a lot of room for improvement.

Scientists have continued to work on improving solar cell efficiency—from green antennas and thin-film perovskites to thin patterned silica.

What about nanoscale etchings?

Researchers at the Center for Functional Nanomaterials at Brookhaven National Laboratory have come up with a way to reduce the reflection of sunlight on glass by etching tiny nanometer-sized cones onto the glass’s surface—making the glass virtually invisible. The cones “have the effect of making the refractive index change gradually from that of air to that of glass, thereby avoiding reflections,” according to a description in a BNL news release.

The conventional way of reducing reflection is to coat a surface with an anti-reflective coating. But adding an additional layer only works for a single wavelength and a single incident light angle, according to the research team’s paper. The nanometer cones are more efficient at eliminating reflection without adding additional layers of material.

“We’re excited about the possibilities,” CFN director Charles Black says in the release. “Not only is the performance of these nanostructured materials extremely high, but we’re also implementing ideas from nanoscience in a manner that we believe is conducive to large-scale manufacturing.”

The researchers used a block copolymer as a template for the self-assembly process, where nanoscale cones with sharp tips were etched onto the surface of the glass 52 nm apart. The resulting surface glare was nearly eliminated.

This cross-sectional image from a scanning electron microscope shows a glass surface textured with 170-nm-tall cones. The cones are packed very close to each other, only 52 nm apart. A two-inch piece of glass has 900 billion cones on its surface. Credit: Brookhaven National Laboratory

In subsequent experiments to measure light reflection, the scientists noted that taller cones reflect less light. They also found that when covered with a nanotextured glass cover, a commercial silicon solar cell can generate as much electric current as one without a cover. The textured glass can also withstand three times as much optical energy from laser pulses than antireflective coatings currently on the market.

“This simple technique can be used to nanotexture almost any material with precise control over the size and shape of the nanostructures,” Aitkur Rahman, assistant professor in the Department of Physics at the Indian Institute of Science Education and Research and research team member, says in the release. “The best thing is that you don’t need a separate coating layer to reduce glare, and the nanotextured surfaces outperform any coating material available today.”

Black believes the research is scalable and mentions that the research team is looking for a partner “to help advance these remarkable materials toward technology.”

And that could be good news for the solar panel industry’s efficiency challenges.

The paper, published in Applied Physics Letters, is “Self-assembled nanotextures impart broadband transparency to glass windows and solar cell encapsulants” (DOI: 10.1063/1.5000965).

Did you find this article interesting? Subscribe to the Ceramic Tech Today newsletter to continue to read more articles about the latest news in the ceramic and glass industry! Visit this link to get started.

Author

Faye Oney

CTT Categories

- Basic Science

- Energy

- Environment

- Glass

- Nanomaterials

Related Posts

Sports-quality ice: From pond side to precision Olympic engineering

February 12, 2026