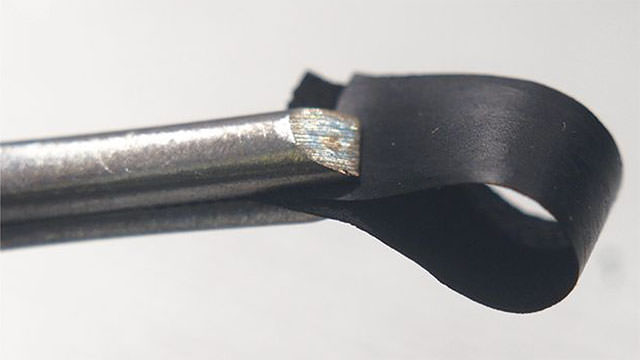

[Image above] The carbon nanotube-based dough can be transformed into arbitrary shapes, such as this freestanding strip. Credit: Northwestern University

Researchers have been studying carbon nanotubes for quite a while. Carbon nanotubes (CNTs) have made significant news in the past year, and we’ve reported it here on Ceramic Tech Today.

Last year, researchers used carbon nanotubes to filter out salt from seawater. In other research, scientists created carbon nanotube yarns that generated electrical energy.

CNTs removed toxic heavy metals from water when combined with quartz fiber. And a budding young scientist earned $25,000 and the title of America’s Top Young Scientist when she used CNTs to develop a lead-detection device.

And, in more recent research, carbon nanotubes were instrumental in recording neural activity in the brain.

CNTs have been studied for their thermal conductivity, mechanical, and other properties for applications in electronics, fuel cells, water desalination, and optical applications.

But one big challenge of making CNTs in large quantities is that they tend to clump together when produced in powder form, making it difficult to separate them into usable forms.

Recently, one researcher and his team reported on a significant advancement that could create more usable CNTs for future research. Led by professor of materials science and engineering in Northwestern University’s McCormick School of Engineering Jiaxing Huang, the research team used an inexpensive mass-produced solvent to disperse CNTs without using additional chemical reactions, according to a Northwestern University news release.

“Aggregated tubes are hard to disperse in solvents,” Huang explains in the release. “And if you cannot get a good dispersion, then you won’t be able to make high-quality nanotube thin films that many applications rely on.”

Huang’s team solved this by using cresol, a chemical found in paints, coatings, and industrial solvents typically used for cleaning and degreasing. In the past, other researchers had tried using other types of additives to coat CNTs, but unlike cresol, those additives changed the surface structures, which altered the respective desirable properties of the CNTs they were studying.

Once the researchers identified the ideal additive in cresol, they discovered that as the concentration of CNTs increased, the material transformed from a liquid dispersion to a paste, then to a gel, and finally—into a thick kneadable dough, according to the release.

“The dough state of nanotubes is fascinating,” graduate student in Huang’s lab Kevin Chiou, says in the release. “It can be readily shaped and molded into arbitrary structures just like playdough.”

Huang notes that their process can reshape nanotubes into polymer-like materials that could be more usable for studying viable applications for CNTs.

“Essentially, this solvent system now makes nanotubes behave just like polymers,” Huang adds in the release. “It is really exciting to see cresol-based solvents make once hard-to-process carbon nanotubes as usable as common plastics.”

Huang’s group has studied carbon materials in past research. For example, they recently demonstrated a less toxic, easily applicable hair dye made from graphene.

And although Huang and his team’s new discovery doesn’t address a specific application for CNTs, it paves the way for future research. “This breakthrough simply makes carbon nanotubes a lot more usable,” he writes in an email, “so people can revisit many carbon nanotube applications or develop new technologies.”

The university has filed a patent, and Huang says they are interested in “demonstrating the feasibility of this new processing strategy in some areas of composite materials.”

The paper, published in Proceedings of the National Academy of Sciences of the United States of America, is “Additive-free carbon nanotube dispersions, pastes, gels, and doughs in cresols” (DOI: 10.1073/pnas.1800298115).

Want to read more articles like this? Subscribe to the Ceramic Tech Today newsletter to continue to receive the latest news in the ceramic and glass industry right in your inbox! Visit this link to get started.

Author

Faye Oney

CTT Categories

- Basic Science

- Material Innovations

- Nanomaterials

Related Posts

Sports-quality ice: From pond side to precision Olympic engineering

February 12, 2026