Check ’em out:

New processes for cost-efficient solar cell production

The photovoltaic industry is pinning its hopes particularly on high-efficiency solar cells that can achieve efficiencies of up to 23 percent. These “HIT” cells (Heterojunction with Intrinsic Thin layer) consist of a crystalline silicon absorber with additional thin layers of silicon. Until now, manufacturers used the plasma-CVD process apply these layers to the substrate: the reaction chamber is filled with silane and with the crystalline silicon substrate. Plasma activates the gas, thus breaking apart the silicon-hydrogen bonds. The now free silicon atoms and the silicon-hydrogen residues settle on the surface of the substrate. However, the plasma only activates 10 to 15 percent of the expensive silane gas; the remaining 85 to 90 percent are lost. The researchers at Fraunhofer IST have now replaced this process: Instead of using plasma, they activate the gas by hot wires. This reduces the overall manufacturing costs of the layers by over 50 percent.

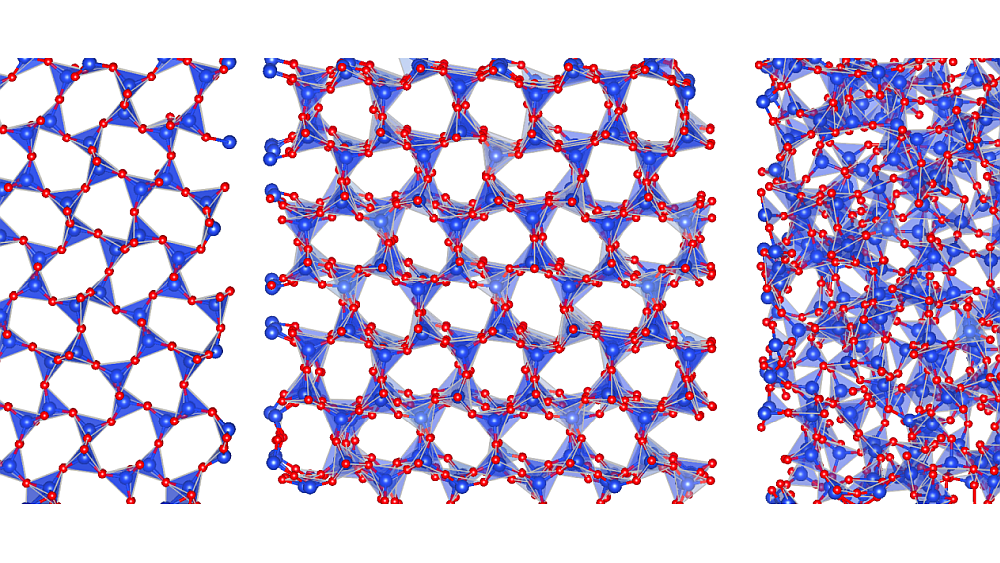

Stanford’s Suncat center and SLAC lab, along with U. Washington, score Materials Genome Initiative metal oxide award

Stanford University’s Center for Interface Science and Catalysis has announced that three scientists, Jens Norskov (PI), Thomas Bligaard and Anders Nilsson have been awarded funds from the DOE Materials Genome Initiative for a project developed together with University of Washington professor Charles T. Campbell and SLAC/Stanford professors Tom Devereaux, Harold Hwang, and Todd Martinez. The award focuses on the discovery of efficient catalytic materials based on inexpensive, earth-abundant elements that could provide the basis for new, energy and atom-efficient processes in industry and for new sustainable energy conversion processes. The work will focus on metal oxides, which are an important class of solid catalysts. The theoretical description of oxide catalysis is not developed to the point where a predictive theory exists. The project aims to establish a predictive theory of transition metal oxide catalysis by developing a broad spectrum of theoretical and experimental approaches to establish a description of surface reactivity. This description can form the basis for design of catalysts based on metal oxides. The awarded funds will be used to develop accurate and efficient electronic structure calculations, and validate the methods by comparing with carefully designed experiments.

AFM measures strength of chemical bonds; researchers can detect impact of electrons shared between atoms

(Ars Technica) Standard atomic force microscopy relies on a needle with a single atom as a tip, and that’s able to probe the electronic conditions in a molecule or surface. But it doesn’t have enough resolution to detect differences in bond length. Instead, the European team behind the new paper in Science used a modified form, in which that single atom is capped by a carbon monoxide molecule, meaning the tip of the needle juts out by two extra atoms. This turned out to be critical. In a number of the samples, the difference in bond length is expected to be at or below the best resolution of atomic force microscopy. As the tip gets pressed down, the carbon monoxide molecule can flex out of the way, behavior that appears to amplify the length of the bond. As a result, the authors were able to discriminate down to bonds that differed by only 0.03 Angstroms. The technique should open up a number of potential opportunities. Molecules that don’t form crystals easily could be imaged with this technique, and the extremely precise control could allow researchers to inject electrons or probe chemical conditions at specific points in a single molecule. All of which could help provide a better understanding of the reactions and catalysts that we rely on for many of the basic materials we use every day.

UAH working to enhance use of off-the-shelf helicopters for military and commercial use

Several UAHuntsville students are working to develop micro-UAVs that could provide low-cost surveillance while enhancing the variety of uses for these UAVs. At altitudes of just a few hundred feet, they can peer down on enemy troops below while remaining practically invisible. The US Army’s Aviation and Missile Research and Development Center (AMRDEC) on Redstone Arsenal provided the original program funding. It is part of work being done by UAHuntsville’s Systems Management and Production Center at Von Braun Research Hall. Directed by Dr. Gary Maddux, SMAP is the largest of UAHuntsville’s 15 research centers. The project’s research supports the ongoing evolution of military intelligence, surveillance, and reconnaissance (ISR). ISR platforms are getting smaller and less costly, important in an era of increasing constraints on military R&D budgets.

New “ATM” takes old phones and gives back green

When new cell phones or tablets enter the marketplace, yesterday’s hot technology can quickly become obsolete–for some consumers. For others, the device still has value as an affordable alternative, or even as spare parts. With support from the National Science Foundation, ecoATM of San Diego, Calif., has developed a unique, automated system that lets consumers trade in those devices for reimbursement or recycling. Using sophisticated artificial intelligence developed through two NSF Small Business Innovation Research grants, ecoATM kiosks can differentiate varied consumer electronics products and determine a market value. If the value is acceptable, users have the option of receiving cash or store credit for their trade–or donating all or part of the compensation to one of several charities. ecoATM finds second homes for three-fourths of the phones it collects, sending the remaining ones to environmentally responsible recycling channels to reclaim any rare earth elements and keep toxic components from landfills. ecoATM is certified to the eWaste environmental standards of Responsible Recycling (R2) and ISO 14001.

CTT Categories

- Basic Science

- Energy

- Modeling & Simulation