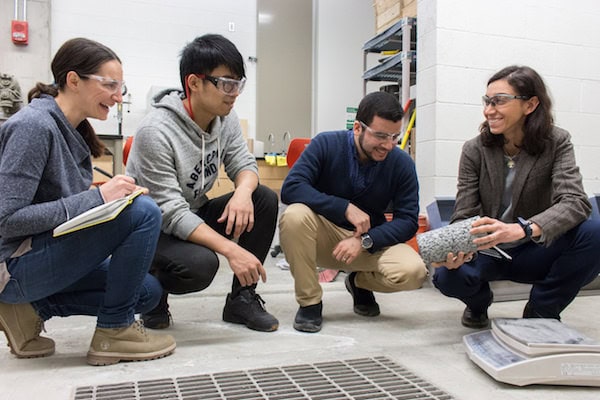

[Image above] Somayeh Nassiri (right) shows students a sample of permeable concrete. Credit: Washington State University

The weather has been especially brutal in the past couple of years. It seems like every few weeks flooding occurs somewhere in the world, displacing residents from their homes.

Many flooding problems occur in areas where there is flat or low land close to large bodies of water with no way for water to drain. Poor or outdated drainage systems exacerbate the problem. Communities have responded with solutions, many of which end up being huge expensive barricades.

And while flood-prone communities continue to blame development, it seems as though most solutions don’t come cheap.

But rather than focusing on multi-million-dollar solutions, some researchers are focusing on altering the pavement.

Several years ago, we shared news of a U.K. company that developed a permeable concrete that prevents pooling of water. And even though pervious concrete is not entirely new, scientists continue to improve upon existing technology.

Researchers at Washington State University (Pullman, Wash.) have developed a type of permeable concrete that actually solves two problems: flooding from water pooling during heavy rains and recycling of an industrial waste product that previously had no reuse applications.

Associate research professor in the Composite Materials & Engineering Center Karl Englund and assistant professor in the Department of Civil and Environmental Engineering Somayeh Nassiri added carbon fiber composite into a pervious concrete mix. The carbon fiber actually increased strength and durability of the concrete.

“In terms of bending strength, we got really good results—as high as traditional concrete, and it still drains really quickly,” Nassiri mentions in a WSU news release.

Carbon fiber is a strong and lightweight polymer used in many applications, including this submarine hull made of six carbon fiber composite sections, clothing, and even heat shields used in spacecraft.

The Pacific Northwest is prone to heavy rains and the research duo has been studying pervious concrete for the past few years. Through their research they discovered that milling, rather than heating or using chemicals, was a less expensive process and could ultimately keep manufacturing costs down at scale.

While carbon fiber composite is an exceptional material to strengthen permeable concrete, it can be costly. The other problem is that there is no market for recycled carbon fiber composite. But what makes the new method interesting is that the researchers are using carbon fiber composite gleaned from the scraps of Boeing’s manufacturing facility. Carbon fiber composite scrap that would otherwise end up in a landfill.

“You’re already taking waste—you can’t add a bunch of money to garbage and get a product,” Englund says in the news release. “The key is to minimize the energy and to keep costs down.”

So what’s the difference between their research and other permeable concrete products on the market? “The innovation in our project is the addition of carbon fiber composite materials that is from the aerospace industry,” Nassiri writes in an email. “This material needs a reuse application, and the use of them in pervious concrete adds value by enhancing durability and strength.”

Water streams through WSU pervious pavement with carbon fiber in a lab test. Credit: Washington State University

Last year the duo conducted structural property tests to determine parameters for rigid pavement thickness design. Their next step is to work on scaling it for manufacturing. “We are working now on implementation and mainstreaming,” Nassiri adds. “When we go through these stages we will have a better idea of cost compared to commercial fibers and other products on the market.”

Englund’s and Nassiri’s research is promising for municipalities and areas in flood plains, as well as manufacturers looking for a recycling solution for carbon fiber composite waste.

“This project is very exciting for us because we work on addressing the needs of industry in finding a reuse application for their waste,” Nassiri adds, “and at the same time working on improving properties of pervious concrete pavements that are beneficial for stormwater management and a desired solution for municipalities.”

The paper, published in the Journal of Materials in Civil Engineering, is “Enhancing mechanical properties of pervious concrete using carbon fiber composite reinforcement” (DOI: 10.1061/(ASCE)MT.1943-5533.0002207).

Did you find this article interesting? Subscribe to the Ceramic Tech Today newsletter to continue to read more articles about the latest news in the ceramic and glass industry! Visit this link to get started.

Author

Faye Oney

CTT Categories

- Cement

- Construction

- Energy

- Environment

- Manufacturing

- Material Innovations

- Modeling & Simulation