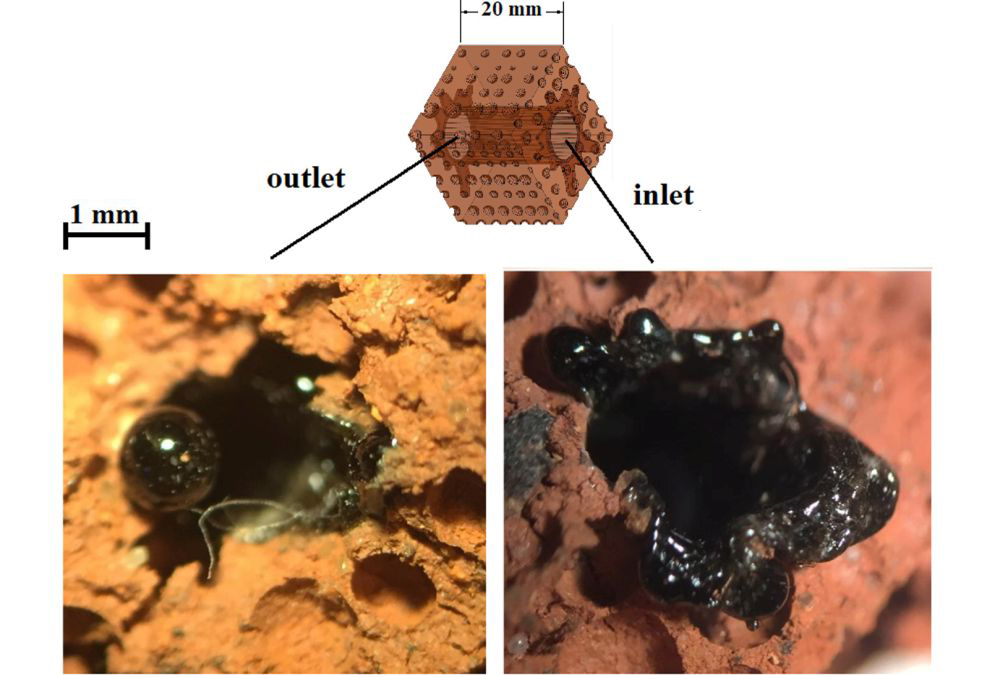

[Image above] Appearance of ejection products from the laser treatment zone of a sample with a length of 20 mm. Credit: Márquez Aguilar et al., International Journal of Ceramic Engineering & Science (CC BY 4.0)

The importance of porous ceramic and glass materials has recently grown because of their versatile, high-tech industrial applications, which cover a range of different fields including biomaterials, catalysis, energy, phase separation, and construction.

The wide use of these materials is due to their appealing properties, such as thermal resistance, low thermal conductivity, relatively low density, and—in the case of open-celled materials—permeability, which carries the ability to filter different fluids and particles, uptake various substances, and release molecules for targeted applications according to predetermined kinetics.

In the fabrication of porous ceramics, a key factor is represented by the design of pore characteristics (e.g., amount, size, shape, degree of interconnectivity) that can be tailored by properly setting the process parameters. In this regard, additive manufacturing has opened new horizons in terms of control over pore features, improvement of performances, and reliability and reproducibility of the printed parts.

Other important fabrication factors include raw materials, type of binder used, and sintering parameters, which can all dictate the final porosity in terms of pore size and distribution. Development of hierarchical ceramics with multiscale porosity from macro- to nanosize is a further challenge disclosing fascinating opportunities.

An upcoming special issue of International Journal of Ceramic Engineering & Science is accepting submissions of original studies describing recent progress in the field of porous ceramics, with a focus on their applications, characterization, and manufacturing processes. Comprehensive reviews providing a critical, prospective view are also encouraged.

Call for paper topics: Thermal and acoustic insulation, construction, filtration and phase separation, catalysis, adsorption, biomedical applications, porous materials for the circular economy, diffusion processes in porous media, ceramic and glass foams, additive manufacturing, mechanical characterization, modeling and simulation of porous ceramics

Keywords: porous materials, mesoporous ceramics and glasses, scaffolds, permeability, sintering, foams, adsorbent, catalytic support, 3D printing, porous composites

Submission instructions and process: Please refer to the Author Guidelines to prepare your manuscript. The submission link is https://wiley.atyponrex.com/journal/CES2. When submitting your work, indicate it is for this special issue by selecting the title “Porous Ceramics” from the drop-down list under the question “Is this submission for a special issue?”

Deadline for submissions: Monday, Dec. 22, 2025

Authors must submit their papers online. For any topic-related questions regarding this special issue, please contact Francesco Baino of Politecnico di Torino at francesco.baino@polito.it.

Author

Jonathon Foreman

Spotlight Categories

- Journal and Bulletin Updates

Related Posts

Volunteer spotlight: Fumie Iizuka

February 19, 2026

Celebrating a half century of engineered ceramics at ICACC 2026

February 17, 2026