Hosted by: ACerS Carolinas Section

Wednesday, September 27, 2023; 5p.m. – 6p.m. Eastern US time

Sponsored by the ACerS Carolinas Section, the September webinar will feature two presentations: Technical Innovation in Bioceramic Design Principles for Regenerative Medicine Applications and ZPTA ceramic bearing surfaces as a preferred choice in joint arthroplasty?

DESCRIPTION

Technical Innovation in Bioceramic Design Principles for Regenerative Medicine Applications

The field of bioactive ceramics has focused primarily on the analysis of the bioactivity property that entails bone to bond directly to the graft material without fibrous encapsulation. Calcium phosphate (CaP) bone grafts was commercialized more than 50 years ago as an alternative for auto and allografts. It was assumed that CaP ceramic will undergo remodeling process like the mineral phase of bone. However, clinical studies demonstrated that osteoclasts cannot resorb hydroxyapatite or biphasic calcium phosphate. Moreover, fibrous encapsulation and soft tissue formation are common observations in defects grafted with CaP ceramics. Several trials to improve the performance of CaP ceramics included doping with ions such as Sr, Si, and Mg known to promote osteoblast differentiation and function. While ionic modifications has improved bone formation, the poor resorbability of the CaP material remains a challenge. Tissue regeneration in a grafted defect is not possible without complete resorbability of the graft material. Design of a bioactive ceramic formula that can dissolve in controlled manner in a physiological solution would eliminate the need for osteoclast-mediated resorption and would provide a space for full bone regeneration. Moreover, stimulation of tissue innervation and vascularization are essential design principal of bioactive ceramic. The dissolution kinetics of FDA cleared Rhenanite-Cristobalite SCPC resorbable bioactive in physiological solution and its effect on promotion of osteogenic differentiation of human osteoblast-like cells, downregulation of human osteoclast primary cells and enhancement of nerve regeneration will be presented. Moreover, the characterization of bone regeneration in human extraction sockets grafted with Shefabone® SCPC granules using immunohistochemical staining will be demonstrated.

ZPTA ceramic bearing surfaces as a preferred choice in joint arthroplasty?

The growing number of hip and knee arthroplasty procedures in most OECD countries require solutions and adequate planning to reduce the future burden of disease and its economic consequences. A growing number of primary arthroplasties are performed on younger and more active patients, consequently this cohort will be at high risk for multiple revisions in their lifetimes. Since revision heavily affects the patient and the healthcare system, the use of implant systems with a lower risk for revision and the use of value-based payment models could be effective strategies for reducing healthcare expenditures in the long-term. Tribological bearing couple represents one among the variables affecting outcomes after joint arthroplasty. The materials chosen must meet not only the properties required by the application, but also the highest quality, beyond just compliance, regardless of commercial demand. This necessitates continuous development of manufacturing technology, which in turn needs continuous research to deepen knowledge in the field of materials science. These are the necessary conditions to ensure the best clinical outcomes, reflected in a low incidence of revision and patient satisfaction.

With the introduction of the Zirconia, Platelet-toughened Alumina (ZPTA) with brand name BIOLOX®delta by CeramTec GmbH (Plochingen, Germany) in 2003, ceramic components have established themselves as durable bearings in hip arthroplasty and become the preferred material on the head side in many countries worldwide. Current best available evidence suggests indeed a favorable long-term benefit-risk-ratio of ZPTA bearings. International joint registries also give strong indications that ceramic composite or mixed ceramic bearings in THA are associated with a lower overall risk of revision, mainly driven by a lower risk of revision for periprosthetic joint infection than the other bearing choices, probably the most serious complication in total joint arthroplasty.

This relentless dedication to improvement of the material knowledge provides the possibility of its use in other applications. For example, ceramic could also become the (bio-)logical alternative in hip resurfacing. Last, ceramic knee arthroplasty implants made of BIOLOX®delta have been introduced in the EU market since 2006. The FDA recently confirmed (2022) the knee replacement device of CeramTec made of BIOLOX®delta ceramic meets the criteria of a Breakthrough Device.

INSTRUCTOR BIOGRAPHIES

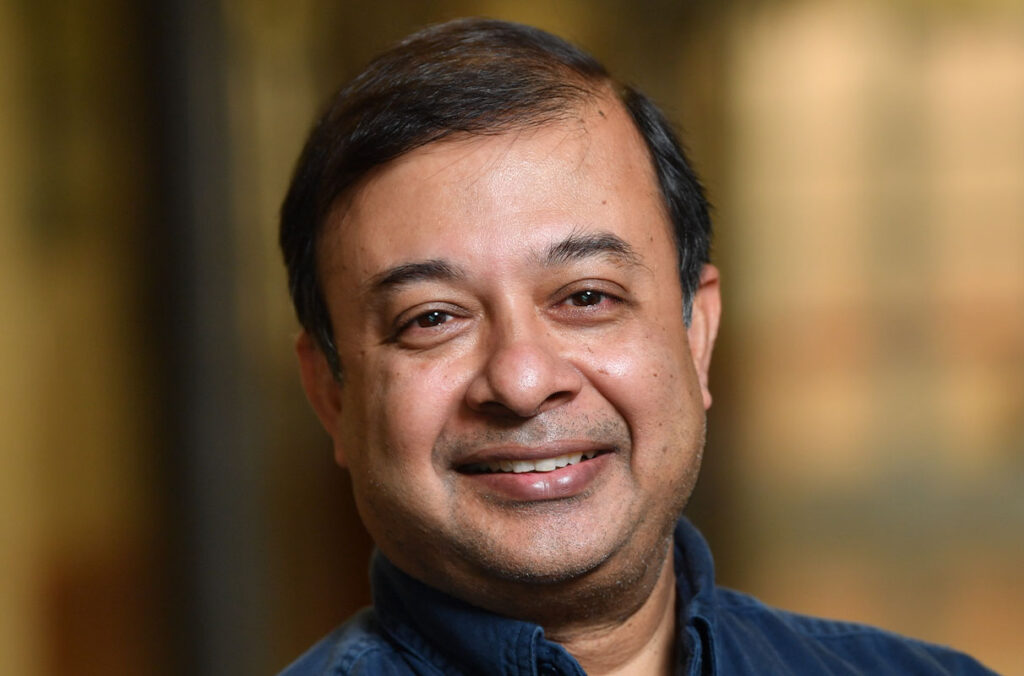

Ahmed El-Ghannam, Ph.D., University of North Carolina, Charlotte

Dr. El-Ghannam is a highly creative biomaterials engineer with several US patents on the design of novel bioactive resorbable ceramics, coating bioceramics on Titanium and cobalt-chromium alloy and additive manufacturing of SiC and SCPC for space, military, and medical applications. The laboratory of Dr. EL-Ghannam got funds from DePuy J&J company, North Carolina Biotechnology center, DoD, NASA and others.

Dr. El-Ghannam has successfully taken a novel bioactive ceramic from the lab bench to the surgery room through FDA approval. He has many collaborators from universities and medical institutes in US and worldwide. Dr. El-Ghannam has been a keynote speaker and a chair in national and international biomaterials conferences and has served as the associate editor of the JBMR-A for the last 16 years. He authored and co-authored biomaterials books and book chapters and have many publications in biomedical materials, engineering, dental and orthopedic journals. He was recognized recently by Stanford University in the list of the top 2% most widely cited scientists in Bioengineering.

Dr. Alan Porporati, Director Medical and Scientific Affairs, Medical Products Division, CeramTec GmbH

Dr. Alan Porporati is currently in charge of medical and scientific affairs at the Medical Products Division of CeramTec GmbH. He has also a visiting researcher position at the University of Trieste. He has 20 years of research experience on zirconia for medical applications and he published three book chapters and a book on this subject. His research interests include (1) biocompatibility of implant materials, (2) elucidating the mechanisms of zirconia phase transformation, and (3) developing innovative ceramic material for implantology.

REGISTRATION

Registration is now closed. If you missed the webinar, ACerS members may view it in the ACerS Webinar Archives. Member log-in required.

If you have any questions, please contact Vicki Evans.

This webinar is brought to you by the ACerS Carolina Section.

To view past ACerS webinars click here.

Author

Vicki Evans

Spotlight Categories

- Section News

U.S. Sections

- Carolinas