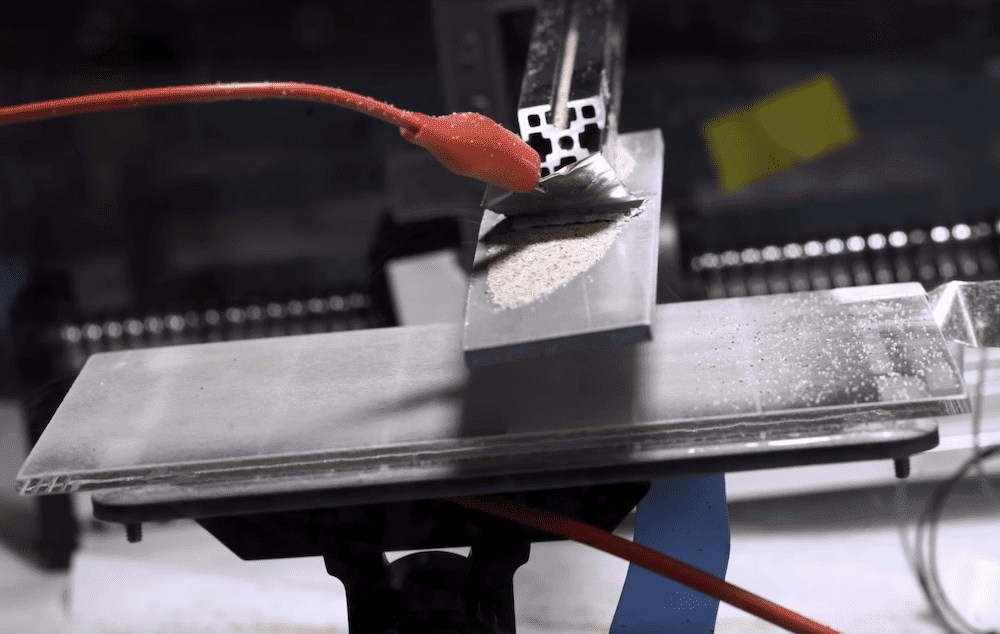

[Image above] Researchers at the Massachusetts Institute of Technology designed a novel electrostatic-based method for removing dust from solar panels. Credit: Massachusetts Institute of Technology (MIT), YouTube

Water is usually the last thing you want contacting your electronic devices. Yet water is an essential part of manufacturing electronic components.

In addition to cooling equipment so it does not overheat, water is used to remove a wide range of organic and inorganic impurities during the manufacturing process to prevent electronics from contamination. The amount of water needed to perform these duties is enormous—fabricating a single integrated circuit on a 30-cm wafer can require approximately 2,200 gallons of water, of which 1,500 gallons are ultrapure.

This massive consumption of water can put a strain on local communities, especially when the fabrication site is in a water-scarce region like a desert. That is why more electronics companies are turning to water recycling and reuse to reduce the amount of fresh water necessary for fabrication.

Manufacturing of electronic components is not the only process that requires vast amounts of water, though. Maintenance of certain devices require tons of water as well, specifically solar panels.

Many large-scale solar farms are in geographical regions that have an abundance of land and sunlight, such as deserts. But while the abundance of sunlight in these areas is favorable for solar power production, there also tends to be significant airborne mineral dust, which accumulates on the solar panel surfaces and reduces efficiency.

Pressurized water jets and sprays are the most common method for removing this dust. And like electronics manufacturing, the amount of water needed for cleaning is immense—studies report that both photovoltaic and concentrated solar power plants consume about 1 to 5 million gallons of water per 100 MW per year for cleaning. With most large-scale solar farms in water-scarce regions, this cleaning regime places a significant strain on local resources.

To reduce water consumption, some small-scale farms clean the panels using manual or robotic dry scrubbing. However, dry scrubbing is not only less effective at removing dust but also introduces irreversible surface scratching that reduces the light transmittance over time.

“Therefore, there is a pressing need for alternate cleaning approaches that can eliminate the giant water footprint of the solar industry not only to reduce the operational costs but also to be truly sustainable,” researchers write in a recent open-access paper.

The researchers are Massachusetts Institute of Technology graduate student Sreedath Panat and professor of mechanical engineering Kripa Varanasi. In their study, they investigate the potential of a novel electrostatic-based method as an alternative to water-based and scrubbing-based cleaning methods.

Electrostatic dust removal is a method of dust collection that uses the action of an electrostatic field to charge dust particles, making it possible to remove them without contact.

Previous groups have tried developing electrostatic-based cleaning solutions for solar panels. But these systems relied on a layer called an electrodynamic screen, which is susceptible to moisture intrusion and electrical shorting. This limitation can be a hindrance for desert-based solar panels, which can experience high relative humidity and low surface temperatures during late night/early morning hours, leading to dew formation.

Panat and Varanasi instead propose a system that works with moisture to remove the dust. In their system, an aluminum bar (top electrode) is passed over a solar panel coated with a 5-nm-thick transparent and conductive layer of aluminum-doped zinc oxide (bottom electrode). When a voltage of ~12 kV is applied across the electrodes, dust particles are repelled from the solar panel surface.

Because charging depends on moisture adsorption, Panat and Varanasi expected that dust removal would depend on humidity as well. This expectation was confirmed when they achieved highly effective dust removal for relative humidity values above 30% and even as high as 95%.

In addition to overcoming the issue of electrical shorting experienced with previous electrostatic-based cleaning solutions, Panat and Varanasi write that their method is beneficial because of the “virtually negligible” power consumption.

“This is because, although the applied voltage is on the order of kilovolts, there is no current flow between the top and bottom electrodes and therefore no electrical power consumption. The only mode of power consumption is that associated with the translation of the moving electrode,” they write.

The video below explains that Panat and Varanasi are currently in the process of scaling up their electrostatic dust removal system so they can conduct field trials at actual solar farms.

Credit: Massachusetts Institute of Technology (MIT), YouTube

The open-access paper, published in Science Advances, is “Electrostatic dust removal using adsorbed moisture–assisted charge induction for sustainable operation of solar panels” (DOI: 10.1126/sciadv.abm0078).

Author

Lisa McDonald

CTT Categories

- Energy

- Environment

- Material Innovations