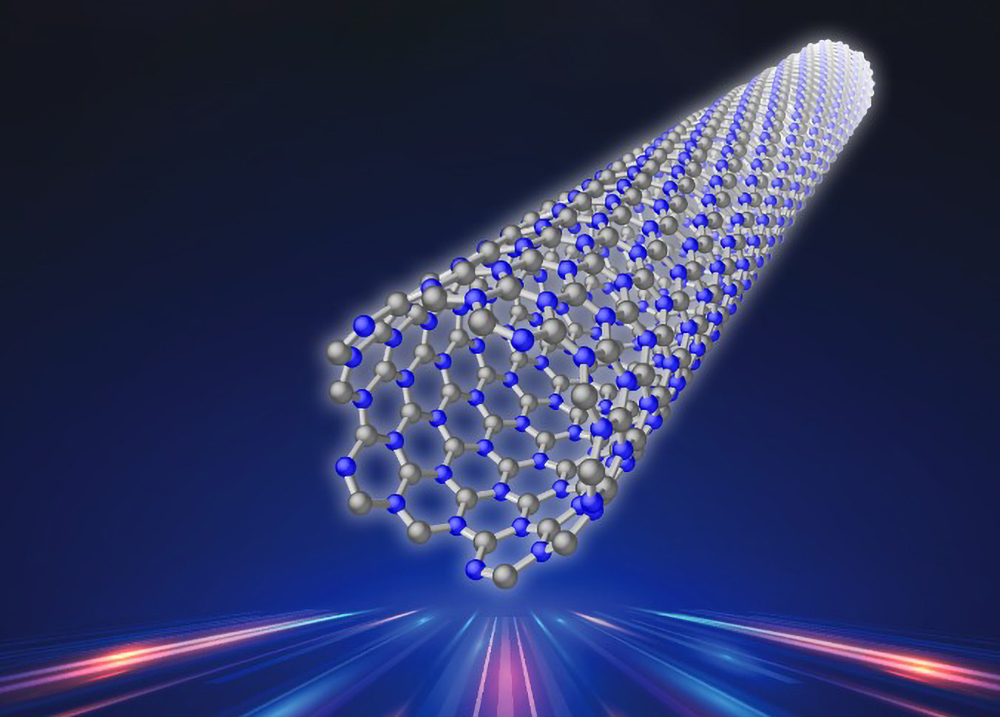

[Image above] Researchers at Pacific Northwest National Laboratory are working with an electron microscope to distinguish the many components of a nuclear waste glass feed as they begin to heat up and melt together to form a liquid glass. Pacific Northwest National Laboratory in Richland, Washington, is a premier research institution pushing the boundaries of nuclear waste disposal and storage. Located a short distance from the Hanford Nuclear Reactor, which produced materials for nuclear energy and weaponry from 1943 to 1987, PNNL is instrumental in developing technology to clean up Hanford. Credit: Pacific Northwest National Laboratory, Flickr (CC BY-NC-SA 2.0)

I recently attended a workshop at a local museum on modeling the future. The event covered issues affecting urban, suburban, and rural environments. Speakers presented current challenges, potential solutions, and new complications arising from those solutions.

One topic relevant to our community was “decarbonization of transportation.” Electric vehicles are the most mature technology in this area. However, new power generation technologies must come online to efficiently charge these vehicles—and they must be carbon-free to achieve the environmental goal.

While the market for technologies that harvest energy from the environment is growing, these technologies will only fully displace fossil fuels once large-scale energy storage solutions are successfully deployed. The most mature carbon-free tech today is nuclear fission, which faces several well-known challenges, notably the radioactive byproducts (waste).

Nuclear waste, and nuclear fuel for that matter, are comprised of unstable isotopes of elements called radioisotopes or radionuclides. These isotopes are chemically identical to their more stable isotopes, differing only in the number of neutrons. That means some isotopes, such as highly soluble cesium 137 and strontium 90, can easily enter the environment if they are not properly stored.

Storage devices for this radioactive material must last decades, centuries, and—in the case of spent fuel and plutonium byproducts—millennia. While techniques such as encasement in steel and concrete are used currently, the industry requires longer-lasting hermetic immobilization methods.

John McCloy from Washington State University is an expert on nuclear immobilization. Below is his introduction to this month’s edition of the Glass: Then and Now series, which explores the field of glass for nuclear waste disposal.

In this International Year of Glass, it is important to reflect on the contributions to society that glass has made. Most of the younger generation can appreciate cell phone cover glass and even optical fibers enabling the internet, but few probably know that glass is protecting humans and the environment from the dispersal of radionuclides.

Radioactive waste has been produced since the beginning of the atomic age in the 1940s. Since the 1970s, it was clear to the scientific community that glass would be the ideal choice as a matrix for immobilizing a waste, which could contain three-quarters of the periodic table in various fractions. Borosilicate glass became the medium of choice for radioactive waste immobilization, due to its high technological maturity at large scale, and its robust chemical durability and radiation stability compared to alternatives.

Radioactive waste vitrification is or has been practiced in France, the United States, Japan, the United Kingdom, India, Germany, and Russia. Research into immobilization of other industrial wastes by vitrification has been conducted in these and many other countries and is practiced in a few.

Radioactive waste vitrification has reached a high level of industrialization with several plants across the world producing glass. The character and composition of wastes differ, requiring tailored technical solutions applied by glass scientists and engineers. Most of the immobilization processes target glasses free or nearly free of crystals though research into the use of glass-ceramics to increase waste loading capacity is ongoing. The main considerations for design and industrialization of vitrified waste form include

– processability (involving properties like electrical conductivity and viscosity),

– final product quality (aqueous chemical durability, radiation stability), and

– economics (waste loading, melter technology, economies of scale).

For most vitrified waste, their final home will be in the ground, either in a shallow disposal site or a deep geological repository, depending on the hazard and local laws. International development of deep geological repositories is advancing quickly. Soon the world will be able to rest easy, knowing that our radioactive wastes, enveloped in glass, are safely tucked away deep beneath the surface of the earth.

– John McCloy, WSU

Articles for Glass for nuclear waste disposal

Author

Jonathon Foreman

Spotlight Categories

- Journal and Bulletin Updates

Related Posts

Volunteer spotlight: Carolina Tallon

January 20, 2026