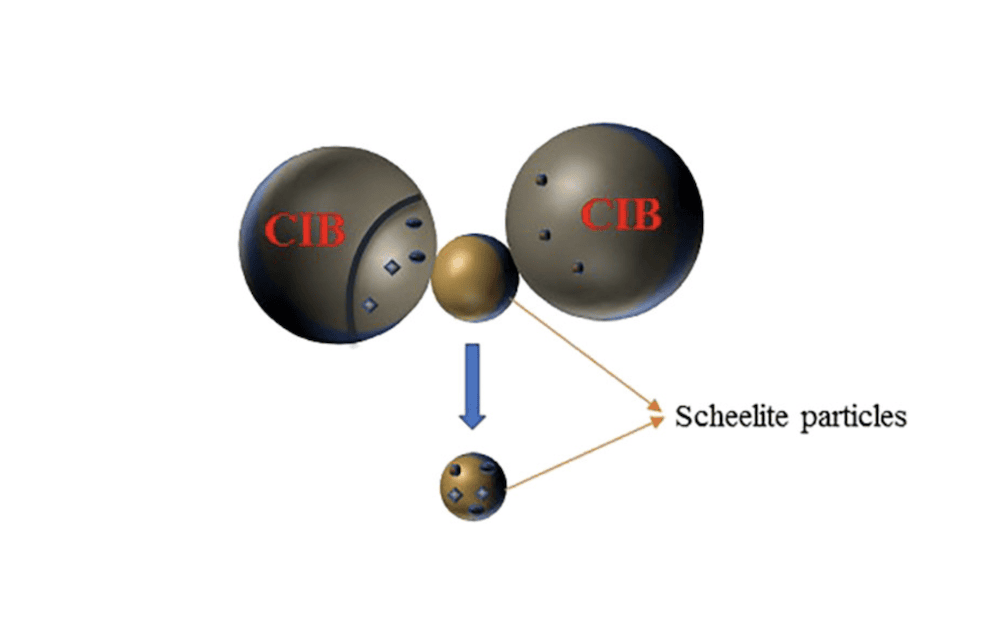

[Image above] Researchers in China investigated how grinding scheelite with cast iron balls can affect the flotation process by contaminating the mineral with iron. Credit: Yao et al., ACS Omega (CC-BY-NC-ND 4.0)

Tungsten is one of the 35 minerals listed as critical in the United States Geological Survey’s annual Mineral Commodity Summaries, which reviews events, trends, and issues for several nonfuel mineral commodities each year. This extremely hard and heat-resistant material is used mainly in cemented carbide parts for cutting and wear-resistant applications, and it is extremely important to the metal working, mining, and petroleum industries, among others.

But where does tungsten come from? Raw materials rarely are mined from the earth in pure form. Rather, ores containing the desired material are mined and then put through a beneficiation process to extract the material.

(Beneficiation is any process that improves the economic value of the ore by removing the gangue, i.e., the commercially worthless material surrounding the desired material. See descriptions of beneficiation processes here.)

In the case of tungsten, wolframite ((Fe, Mn)WO4) and scheelite (CaWO4) are the two main minerals that are mined commercially as a source of tungsten. Wolframite traditionally is the primary ore of tungsten, but in recent years the world has witnessed an increasing depletion of easily beneficiated wolframite resources. This depletion has led the industry to devote considerable interest to scheelite resources instead.

To obtain tungsten from scheelite, one of the main beneficiation methods used is flotation. Flotation involves altering an ore’s surfaces to be either hydrophobic or hydrophilic, i.e., either repel or attract water. When the ore is placed in aerated water, the bubbles attract and then float the hydrophobic minerals, leaving the hydrophilic component in the underflow as tailings.

Much research on improving the flotation of scheelite looks at adjusting the flotation reagents, or the substances used to alter hydrophobicity and hydrophilicity. However, researchers often overlook another important factor that could potentially affect the scheelite flotation performance—grinding media.

Before beginning the flotation process, the ore is scrubbed to condition its surface for further beneficiation. Cast iron balls are a first-choice media for grinding scheelite because of their cheap price and high grinding efficiency, but they can result in the ore having iron contamination.

Previous studies on materials such as sulfide minerals, platinum group metal, and carbonate minerals showed iron contamination has deleterious effects on flotation. “However, the effects of CIB [cast iron ball] grinding on the flotation behavior of scheelite are still unclear,” researchers write in a recent open-access paper.

The researchers come from Wuhan University of Science and Technology (China), and they decided to fill this gap in knowledge by studying the effects of contamination themselves. They collected scheelite samples from Jiangxi Province, China, and then ground the scheelite using either cast iron balls or ceramic balls. (Previous studies showed using inert grinding media such as ceramic balls can enhance the sulfide flotation performance.)

They used a variety of tests to determine the effects of grinding material on the flotation process, including zeta potential measurements, dissolved oxygen tests, inductively coupled plasma-atomic emission spectroscopy tests, scanning electron microscopy-energy dispersive spectroscopy tests, and X-ray photoelectron spectroscopy tests.

Ultimately, the researchers concluded that scheelite ground by cast iron balls has a lower flotation recovery than scheelite ground by ceramic balls. They attribute this finding to the coating of iron species on the scheelite surface, which impedes adsorption of sodium oleate, a reagent that creates a hydrophobic film on the mineral surface.

“This research will guide the grinding medium selection in beneficiation of scheelite ore in industry and effectively improve the scheelite flotation performance, which is significant in the efficient use of tungsten resources,” they write.

The open-access paper, published in ACS Omega, is “Effects and mechanisms of grinding media on the flotation behavior of scheelite” (DOI: 10.1021/acsomega.0c05104).

Update 02/09/21 – The initial explanation of flotation had the terms hydrophobic and hydrophilic reversed. The sentence has been corrected.

Author

Lisa McDonald