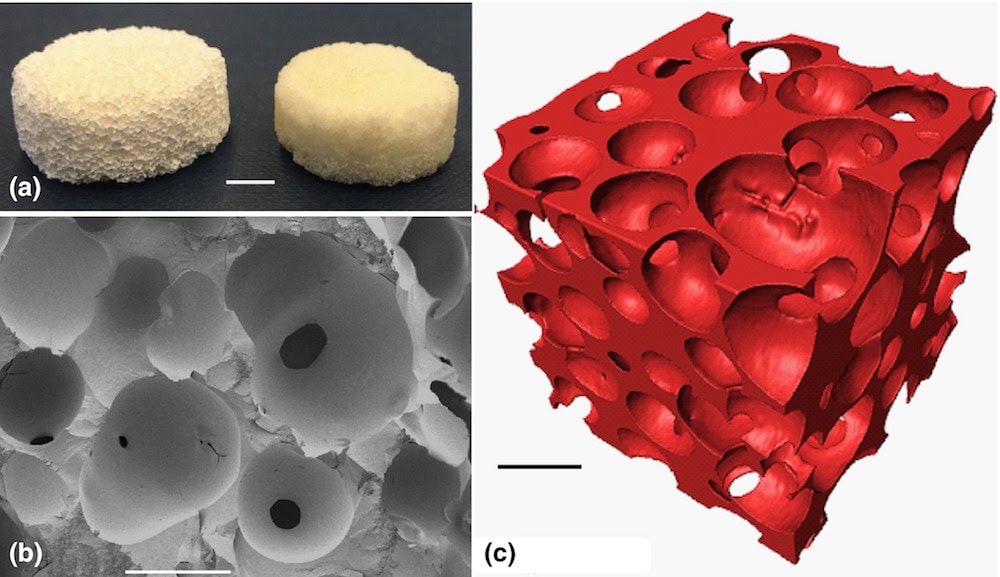

[Image above] Creating bioactive glass scaffolds like the one pictured above is challenging. A recent study looks into factors hindering the process. Credit: Poologasundarampillai et al., International Journal of Applied Glass Science/Wiley

I have been hard on my teeth, and I am getting to the age where replacements are necessary. I recently had a crown installed and the dentist discussed the pros and cons of zirconia- versus porcelain-coated metal. As he talked, I couldn’t help but wish bioglass-infused toothpaste existed when I was young.

The discovery of practical, bioactive glass materials took place nearly 50 years ago. In that time, bioglass made substantial impacts on healthcare, with scientists, engineers, medical and dental professionals, and businesspeople working to bring many products to market for consumer and hospital use.

When placed in living tissue, bioglass stimulates tissue growth by dissolving and elevating concentrations of calcium and phosphates, both important building blocks for cell generation. Bioglass is particularly effective in places where disease or injury has caused damage and cell death. Currently, powdered forms of bioglass are mixed with other substances, such as toothpaste or blood, and spread over an injured area.

However, with large areas of damage, these powdered mixtures tend to move around, resulting in inconsistent or incomplete repairs. Bioglass scaffolds for bone and soft tissue engineering could solve this problem.

Scaffolds are rigid, yet porous “frameworks” that can be shaped to fit the missing or damaged regions. The scaffolds integrate into the existing tissue while providing a template for the new tissue. The porosity enables growth of new blood vessels as well. To put this in perspective, scaffolds may one day allow us to regrow a bad tooth rather than covering it with a crown.

Unfortunately, bioglass scaffolds are not available commercially because researchers struggle to produce bioglass scaffolds that are strong and porous at the same time. Complete densification of the glass framework is necessary for maximum strength and crack resistance. Unfortunately, most bioglasses, especially the popular 45S5, produce weak frameworks prone to cracking because they do not sinter to full density.

During sintering, high surface area particles consolidate via viscous flow in order to reduce surface energy. Crystallization prevents viscous flow by locking the atoms into alternate low-energy structures.

Understanding the parameters of crystallization for 45S5 and other bioglasses will help researchers develop more effective sintering methods. And that information is what researchers explored in the recent open-access paper “Sintering and concomitant crystallization of bioactive glasses.”

Comparison of sintering profiles and microstructures after sintering for 45S5 and a research bioglass (by X-ray computer tomography and electron microscope). Credit: Blaeß et al., International Journal of Applied Glass Science/Wiley (CC BY 4.0)

The researchers—from The Federal Institute for Materials Research and Testing and the University of Jena in Germany, and the University of Birmingham in the U.K.—found that when crystallization occurs within the temperature region of sintering, sintering stops. (This is clearly the case for 45S5 glass.) For compositions with higher alkaline earth (calcium, magnesium) to alkali (sodium, potassium) ratios, crystallization occurs at temperatures above the sintering region for fine powders (under 32 µm) and complete densification is possible.

The researchers note crystallization behavior of larger particles differs from that of smaller particles. They also observe that larger particles sinter more slowly.As a result, full sintering does not occur prior to the start of crystallization, and full density is not achieved. The researchers say this information can be useful for designing optimal particle size distributions and firing schedules.

Though the researchers provide great insight into the densification of the various bioglasses, they urge more research is needed to create scaffolds with complex geometries and consistent pore structures. Specifically, they state more information is needed on viscosities of the glasses between the glass transition and crystallization onset temperatures.

I look forward to seeing future papers on this topic.

The open-access paper, published in International Journal of Applied Glass Science, is “Sintering and concomitant crystallization of bioactive glasses” (DOI: 10.1111/ijag.13477).

Author

Jonathon Foreman

CTT Categories

- Basic Science

- Biomaterials & Medical

- Glass

Related Posts

Sports-quality ice: From pond side to precision Olympic engineering

February 12, 2026