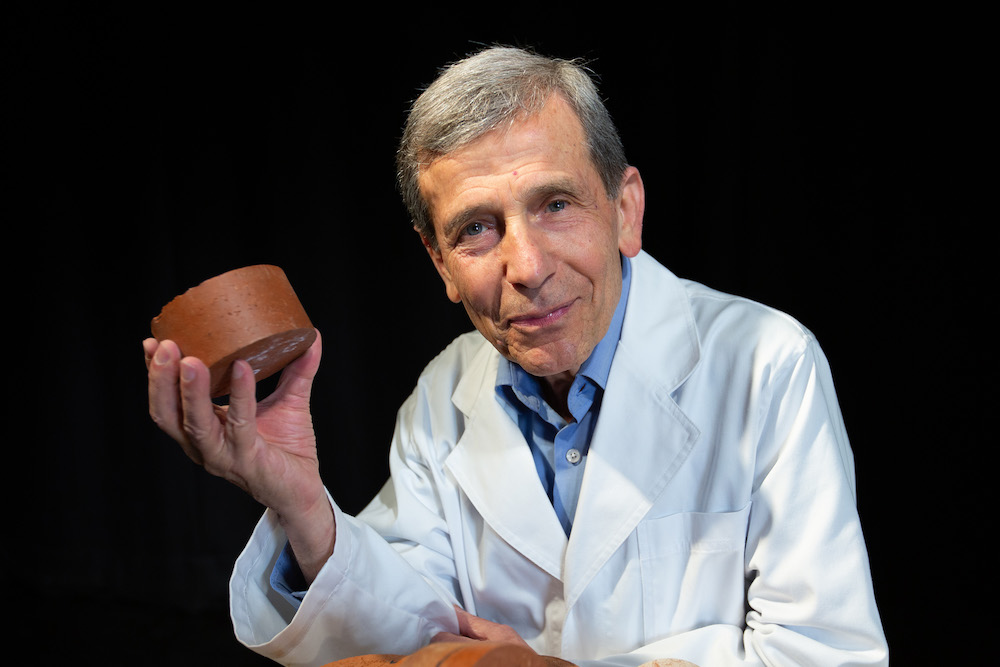

[Image above] Abbas Mohajerani, associate professor at RMIT University, with a biosolids brick. Mohajerani and his team showed biosolids-enhanced bricks are more environmentally friendly than traditional bricks. Credit: RMIT University

Most people know about the overwhelming plastic waste polluting our world (as evident by public pressure successfully convincing companies to ditch plastic straws). Far fewer people, though, know about biosolids waste.

Biosolids are nutrient-rich organic materials that come from dewatered and appropriately-treated wastewater sludge, which itself comes from the wastewater treatment process. While many biosolids are used as fertilizers or in land rehabilitation projects, other biosolids end up in landfills or stockpiles, where they then contribute to greenhouse gas emissions.

Fortunately, even though the general public may be unaware of biosolids, the construction industry is not. Studies on keeping biosolids out of stockpiles by reusing them in construction materials include incorporating biosolids in road embankments and concrete.

Biosolids stockpile at Melbourne’s Western Treatment Plant. Credit: Abbas Mohajerani, Buildings (CC BY 4.0)

One great new option under investigation is the use of biosolids to make bricks.

Because brick composition is quite flexible, bricks are capable of incorporating a high percentage of waste. And with about 1,500 billion bricks produced globally each year, that offers a lot of opportunities to incorporate waste. Already, researchers have tried incorporating other troublesome waste materials, including cigarette butts, paper processing residue, and glass.

Last November, we reported on a team of University of Cape Town researchers who successfully made bio-bricks out of human urine. Now, researchers at RMIT University in Australia picked up the bio-bricks mantle.

“More than 3 billion cubic metres of clay soil is dug up each year for the global brickmaking industry,” Abbas Mohajerani, lead investigator and associate professor in RMIT’s School of Engineering, says in an RMIT University news release. “Using biosolids in bricks could be the solution to these big environmental challenges.”

Mohajerani has previously worked on using cigarette butts to make asphalt pavement and bricks. In the current experiment on biosolids, Mohajerani explains the research addresses two environmental issues—stockpiles of biosolids and excavation of soil required for brick production. They tested feasibility of the concept by incorporating 10 to 25 percent of biosolids into fired clay bricks, and then examined each brick’s physical, chemical, and mechanical properties.

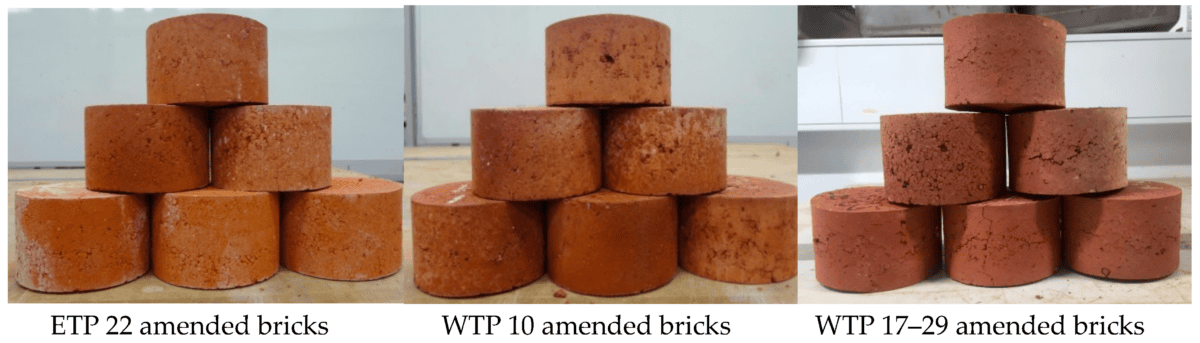

Biosolids-enhanced bricks were created using biosolids from Melbourne’s Eastern Treatment Plant (ETP 22) and Western Treatment Plan (WTP 10 & WTP 17-29). Credit: Abbas Mohajerani, Buildings (CC BY 4.0)

The researchers found biosolids-enhanced bricks passed compressive strength tests and largely trapped heavy metals within the brick after firing. Additionally, bio-bricks showed lower thermal conductivity than traditional bricks, thereby enhancing the bricks’ insulating abilities.

However, the finding most significant in terms of environmental impact had to do with brick production—brick firing energy fell 12.4 to 48.6 percent for bricks incorporating biosolids with organic contents of 7.1 to 27.79 percent!

“Based on the results found in this comprehensive study, this paper proposes the inclusion of a minimum of 15% biosolids content into 15% of brick production in order to completely recycle all the approximately 5 million tonnes of annual leftover biosolids production in Australia, New Zealand, the EU, the USA and Canada,” the researchers write in the paper.

We can use up all leftover biosolids by only modifying 15 percent of brick production? Sign me up—as long as there is no accompanying smell!

The open-access paper, published in Buildings, is “A proposal for recycling the world’s unused stockpiles of treated wastewater sludge (biosolids) in fired-clay bricks” (DOI: 10.3390/buildings9010014).

Author

Lisa McDonald

CTT Categories

- Biomaterials & Medical

- Construction

- Environment