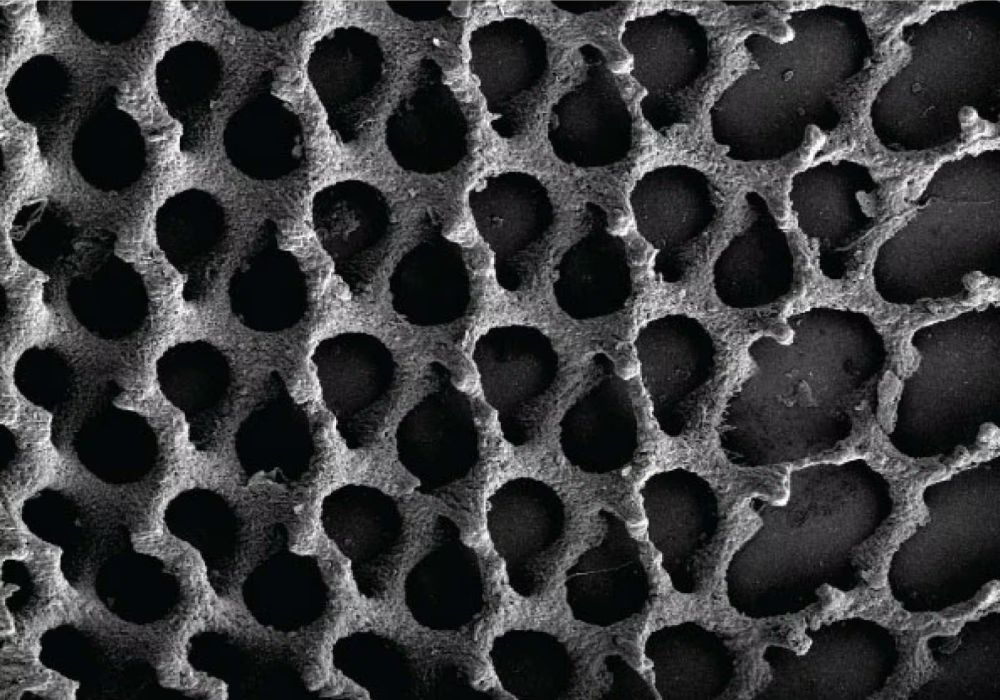

[Image above] Scanning electron microscopy image of hydroxyapatite-based electrospun fibers. Electrospun ceramic fibers have a lot of potential in the field of bone tissue engineering. Credit: Wu et al., Journal of the American Ceramic Society

Of all the materials used to repair, replace, and enhance parts of the human body, ceramics hold a particular advantage. Many ceramics are inherently biocompatible, chemically resistant, and inert, which allows them to be integrated into the body without adverse side effects.

Bioceramics have been used for joint replacements, tooth implants, and tissue scaffolds, among other applications. Calcium phosphate and hydroxyapatite are two commonly used bioceramics because these materials naturally occur in the body.

The inherent brittleness of bioceramics makes them difficult to shape using traditional subtractive manufacturing (machining) methods. So, for weight-bearing applications such as joint replacements, metal–ceramic composites of aluminum, carbon, or titanium are commonly the first choice because of their tolerance for being shaped.

Additive manufacturing techniques are growing in popularity as a way to fabricate bioceramics because it allows these materials to be formed in intricate shapes without the stresses of machining. Additive manufacturing techniques used for fabricating bioceramics include digital light processing and direct ink writing (here and here).

However, additive manufacturing techniques typically are limited in their ability to produce composite materials. Electrospinning has emerged as an alternative to additive manufacturing to produce nanoscale, composite bioceramic materials.

The basics of electrospinning

Electrospinning technology has roots in the 19th century, but it really came into its own in the 1990s when electron microscopes were developed that could visualize the micro- and nanofibers produced in this way.

Electrospinning involves extruding a polymeric solution or melt through a thin needle with a diameter ranging from tens of nanometers to several micrometers. The application of an electric force causes the solution to take on a cone shape that gets ejected in a charged stream from the needle onto a (typically) solid platform called the collector, where it solidifies into thin fibers.

A liquid bath collector is also an option. Using a liquid collector allows additional materials to be embedded in the fibers and promotes the development of pores, which are essential for bone cell adhesion.

Electrospinning is relatively easy to set up and uses low-cost equipment. Adjusting the parameters of the electric field strength, the needle diameter, the distance between the needle and the collector, the solution viscosity and flow rate, and the environmental conditions (e.g., humidity and temperature) can change the characteristics of the resulting fibers.

Factors that affect the electrospun fiber formation and corresponding outcomes. Credit: Wan et al., Exploration (CC BY 4.0)

Electrospinning for bone tissue engineering

Electrospinning is emerging as a beneficial tool in the field of bone tissue engineering. Bone tissue engineering involves designing materials to treat bone defects and losses caused by genetic mutations, trauma, or disease. When the defects or losses are severe, it may be necessary to replace the bone or to encourage bone regrowth using a bioceramic scaffold.

Electrospinning allows for the creation of bioceramic scaffolds consisting of composite nanofibers that mimic the bone extracellular matrix (ECM). ECM is a biocomposite of collagen (a protein) and hydroxyapatite that forms a scaffold upon which the bone cells (osteoblasts) can grow.

Materials used in the electrospinning of bioceramic composites can be inert, resorbable, or bioactive, depending on whether they need to remain unchanged, dissolve, or participate in a physiological process such as bone regrowth. Biocompatible polymers such as poly-ε-caprolactone or poly(lactic acid) are often used in combination with carbon nanotubes or hydroxyapatite to produce nontoxic bioceramic composites.

The ability to create bioactive nanocomposites with controllable shapes and tunable mechanical properties is a huge advancement in bone tissue engineering technology. Polymeric–inorganic electrospun composites can be functionalized to allow material release, protein adsorption, or cell adhesion. It is even possible to produce materials with embedded antibiotics for controlled release, to prevent or treat bone infections.

Learn more about the potential of electrospinning in the field of bone tissue engineering in the articles below.

Further reading

Dejob et al., “Electrospinning of in situ synthesized silica-based and calcium phosphate bioceramics for applications in bone tissue engineering: A review,” Acta Biomaterialia 2021, 123: 123–153.

Haider et al., “A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology,” Arabian Journal of Chemistry 2018, 11(8): 1165–1188.

Jang et al., “Electrospun materials as potential platforms for bone tissue engineering,” Advanced Drug Delivery Reviews 2009, 61(12): 1065–1083.

Author

Becky Stewart

CTT Categories

- Biomaterials & Medical