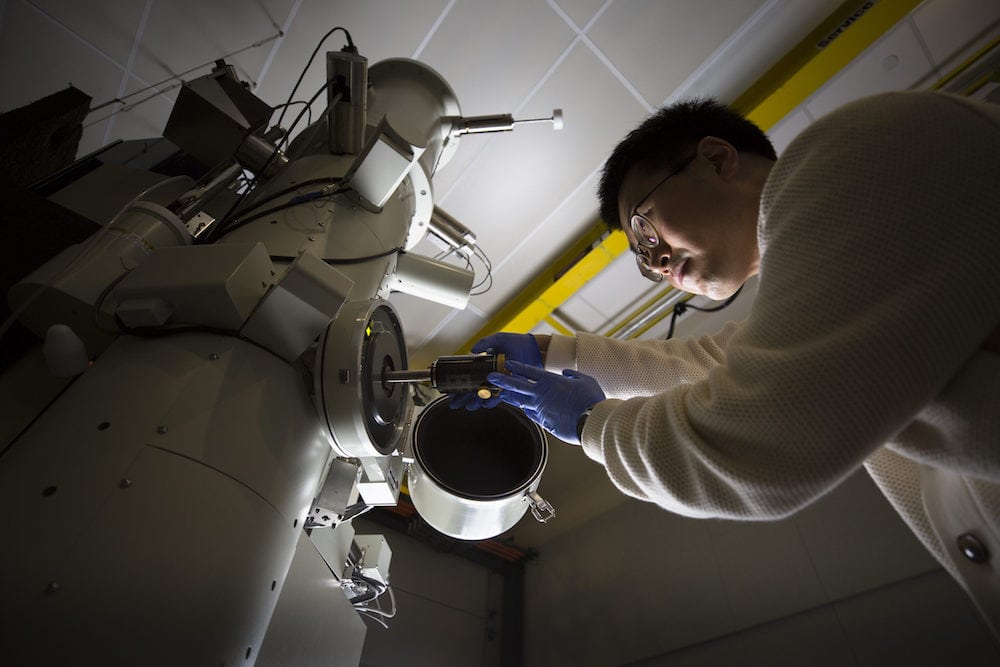

[Image above] Jiseok Gim, materials science and engineering Ph.D. candidate, loads a sample into the JEOL 3100R05 electron microscope in the Michigan Center for Materials. Gim and a group of scientists used electron microscopy to investigate the nanomechanics of nacre’s strength. Credit: Evan Dougherty, Michigan Engineering

Nacre is a material that represents more than the sum of its parts.

Also known as mother-of-pearl, scientists have long studied this iridescent mollusk shell lining to unlock its secrets, as nacre is an incredibly strong and resilient biomaterial.

For instance, scientists recently developed bacteria-based methods to fabricate synthetic nacre on earth and beyond, and nacre’s structure even inspired techniques for 3D-printing body armor.

Nacre’s structure and composition are both known—nacre is composed of polygonal platelets of crystal calcium carbonate, or aragonite, that are stacked up like bricks and mortared together with organic material. Yet nacre as a material is much tougher than would be predicted based upon the properties of these individual parts.

So what is the secret to nacre’s strength?

A new open-access paper delves into the nanomechanics of nacre to unveil how its structure provides the biomaterial with such exceptional abilities.

“We humans can make tougher materials using unnatural environments, for example, extreme heat and pressure. But we can’t replicate the kind of nano-engineering that mollusks have achieved,” Robert Hovden, senior author and assistant professor of materials science and engineering at the University of Michigan, says in a university press release. “Combining the two approaches could lead to a spectacular new generation of materials, and this paper is a step in that direction.”

Hovden and a team of scientists from the University of Michigan (Ann Arbor, Mich.), Macquarie University (Sydney, Australia), Université de Bourgogne Franche-Comté (Dijon, France), and University Erlangen-Nürnberg (Erlangen, Germany) set out to track what happens to nacre’s nanostructure when stress is applied. Using high-resolution scanning/transmission electron microscopy (S/TEM), they watched in real-time how samples of nacre respond to nanoindentation.

The results reveal that although the organic component of nacre represents only a small proportion of the material (2–5 wt.%), it has a disproportionately big impact on its performance.

When the scientists compressed the nacre samples with a nanoidentor tip, they saw that individual aragonite bricks within nacre’s structure compressed together, squishing the organic mortar out of the way. With the organic material pushed to the side, individual bricks came into contact with one another, structurally locking with neighboring bricks.

The bricks joined together to form bulk aragonite, which can better distribute strain within the material compared to those individual bricks. This joining allows nacre to have better resilience under pressure, as the organic material absorbs the applied energy and helps prevent the hard biomaterial from cracking (or at least limiting crack propagation).

By shifting its structure, nacre can absorb about 1–3 times more mechanical energy than monolithic aragonite. “So this transition between local deformation and large scale deformation is what makes nacre so tough,” Hovden says in the video below.

Credit: Michigan Engineering; YouTube

Incredibly, the entire process is reversible—when strain is removed, the organic material squishes back into its mortar position between the bricks, setting the process up to repeat again. This reversibility provides nacre with exceptional resilience to repeated deformation, allowing the material to exhibit its impressive strength, hardness, and ductility.

The team’s S/TEM results open up the possibility of using similar experimental approaches to investigate a broad range of other materials. And, with a better understanding of how nacre’s structure makes the biomaterial so tough, the scientists think their results might inspire approaches to nanoengineer composite surfaces that are synthetically tough as well.

The open-access paper, published in Nature Communications, is “Nanoscale deformation mechanics reveal resilience in nacre of Pinna nobilis shell” (DOI: 10.1038/s41467-019-12743-z).

Author

April Gocha

CTT Categories

- Biomaterials & Medical

- Nanomaterials