Check ’em out:

September California workshop to explore plans for National Network for Manufacturing Innovation

The Advanced Manufacturing National Program Office, in partnership with state and national organizations, is inviting interested parties to the third in a series of regional workshops to introduce and encourage public discussion of a planned National Network for Manufacturing Innovation. “Designing for Impact III: Workshop on Building the National Network for Manufacturing Innovation” will be held on Sept. 27, 2012, at the Arnold and Mabel Beckman Center of the National Academies of Sciences and Engineering at the University of California, Irvine. Local hosts and co-organizers for this workshop event include the National Academy of Engineering, the National Academies’ University-Industry Research Roundtable and University-Industry Demonstration Partnership, NASA’s Jet Propulsion Laboratory and UC Irvine. The AMNPO was established to coordinate federal resources and programs across agencies to enhance technology transfer to U.S. manufacturers. The office is hosted by the National Institute of Standards and Technology in partnership with DOD, the Department of Education, DOE, NASA and NSF.

How to line a thermonuclear reactor

(Science Now) Since no perfect material exists, the plan is to compromise and use two different materials. Most of the first wall would be coated with beryllium, which is the least plasma-polluting metal but has a low melting point if it comes into contact with the plasma. At the bottom of the torus is a structure called the divertor, which is like the reactor’s exhaust pipe because it extracts helium from the plasma. The divertor is deliberately in contact with the plasma and so needs a tougher coating. For this, the plan is to use tungsten, which can withstand the heat in the divertor region-lower than in the bulk of the plasma-but if some does get eroded away, it poisons the plasma pretty badly. The tungsten elements of the divertor “are designed to handle steady heat flows twice as large as those experienced by the nose cone of the Space Shuttle on reentry into the Earth’s atmosphere,” says physicist Richard Pitts, leader of the Plasma-Wall Interaction and Divertor Physics Group at ITER.

Dimensional study of the caging order parameter at the glass transition

(PNAS) The glass problem is notoriously hard and controversial. Even at the mean-field level, little is agreed upon regarding why a fluid becomes sluggish while exhibiting but unremarkable structural changes. It is clear, however, that the process involves self-caging, which provides an order parameter for the transition. It is also broadly assumed that this cage should have a Gaussian shape in the mean-field limit. Here we show that this ansatz does not hold. By performing simulations as a function of spatial dimension d, we find the cage to keep a nontrivial form. Quantitative mean-field descriptions of the glass transition, such as mode-coupling theory, density functional theory, and replica theory, all miss this crucial element. Although the mean-field random first-order transition scenario of the glass transition is qualitatively supported here and non-mean-field corrections are found to remain small on decreasing d, reconsideration of its implementation is needed for it to result in a coherent description of experimental observations.

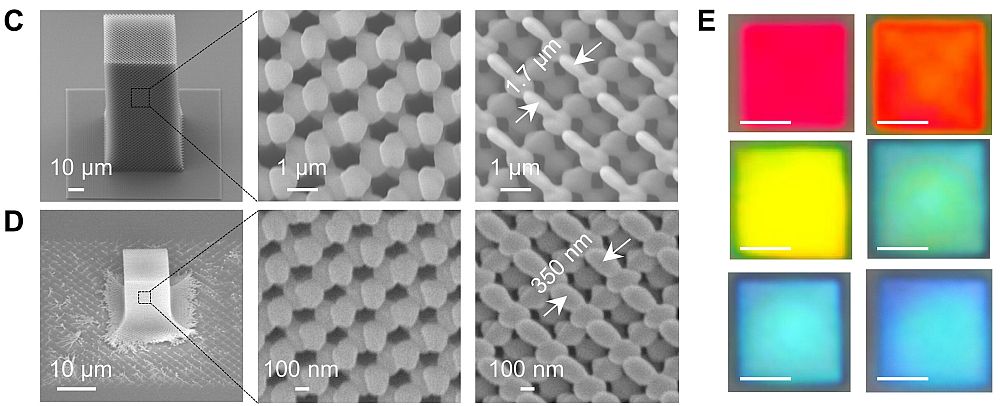

Singapore team’s 100,000 DPI image pushes limits of resolution

(Wired) A method of printing nanometer-tall pillars has been used to create full-colour images with a resolution pushing up against the maximum theoretical limit. The Singapore-based team, who describe their work in a paper in Nature Nanotechnology, created pixels using tiny nanoscale posts, with silver and gold nanodiscs on top. The distance between these structures, and their diameter, sets the colour of light that they reflect. As proof of concept, the researchers, based at Singpore’s Agency for Science, Technology and Research, printed a 50 x 50 micrometer image of Lena Söderberg, a Swedish model from a 1972 issue of Playboy magazine, often used in image processing experiments. They used electro-beam lithography to cover a silicon wafer with pillars made from an insulating material, then deposited the nanodiscs on top and coated the surface of the wafer with metal to reflect the coloured light and make the image brighter. The resulting image came in at an impressive 100,000 DPI resolution. That’s right up at the maximum possible resolution that can be achieved. Even under the best microscope, a limit can be reached due to the wavelength of visible light. The other benefit of using nanostructures to create colour is that they’ll never fade. So long as the pillars don’t corrode and change shape, the image won’t change over time.

Making stretchable electronics: Startup prepares to manufacture electronics that conform to skin, arteries, and organs

(Technology Review) MC10, a startup in Cambridge, Massachusetts, is getting ready to commercialize highperformance electronics that can stretch. The technology could lead to such products as skin patches that monitor whether the wearer is sufficiently hydrated, or inflatable balloon catheters equipped with sensors that measure electrical misfiring caused by cardiac arrhythmias. Microelectronics have long “depended on a rigid, brittle wafer,” says David Icke, MC10’s CEO. MC10 uses a few tricks to change that. To make both the hydration-sensing patch and the catheter, gold electrodes and wires just a few hundred nanometers thick are deposited on silicon wafers by conventional means, then peeled off and applied to stretchable polymers. The serpentine wires elongate when the polymers stretch, either when the balloon inflates in the heart or as the patch moves around on the skin. The electrodes measure electrical impedance to detect the electrical signals in cardiac tissue or moisture levels in the skin. The company is building on lab prototypes made by University of Illinois materials scientist John Rogers, a company cofounder. Rogers’s technologies have advantages over other approaches to flexible electronics. For example, organic polymer electronics can only bend, not stretch, and they are slower than devices made of inorganic semiconductor materials or precious metals such as gold, so they can’t provide precise real-time biological readings.

New solar panels made with more common metals could be cheaper and more sustainable

(ACS) Shingles that generate electricity from the sun, and can be installed like traditional roofing, already are a commercial reality. But the advance-a new world performance record for solar cells made with “earth-abundant” materials—could make them more affordable and ease the integration of photovoltaics into other parts of buildings, the scientists said. The new photovoltaic technology uses abundant, less-expensive materials like copper and zinc—”earth-abundant materials”—instead of indium, gallium and other so-called “rare earth” elements. These substances not only are scarce, but are supplied largely by foreign countries, with China mining more than 90 percent of the rare earths needed for batteries in hybrid cars, magnets, electronics and other high-tech products. At the national meeting of the American Chemical Society, Harry Atwater and James C. Stevens described successful efforts to replace rare earth and other costly metals in photovoltaic devices with materials that are less-expensive and more sustainable. Atwater and Stevens described development and testing of new devices made with zinc phosphide and copper oxide that broke records for both electrical current and voltage achieved by existing thin-film solar energy conversion devices made with zinc and copper. The advance adds to evidence that materials like zinc phosphide and copper oxide should be capable of achieving very high efficiencies, producing electricity at a cost approaching that of coal-fired power plants. That milestone could come within 20 years, Atwater said.

Synthesizing binary metal oxide nanotubes

(MaterialsViews) Binary metal oxide nanotubes are an important emerging class of materials because of their potential applications in many fields such as catalysis and ferroelectrics. Although template-assisted synthesis based on interfacial reaction is one of the most effective approaches for preparing hollow, single metal oxide (MOx) structures, this method is rarely employed for the synthesis of hollow binary metal oxide (M1-M2Ox) structures. Now, a new, simple avenue for the general synthesis of hollow structured binary oxide has been reported by Guozhu Chen, Federico Rosei, and Dongling Ma from the Institut National de la Recherche Scientifique in Montreal, Canada. The researchers described an interfacial oxidation/reduction-directed synthesis of hollow binary oxide structures with different shapes (nanotubes and nanocubes) and compositions (Ce-MnOx, Co-MnOx and Ce-FeOx). For example, Ce-MnOx nanotubes were fabricated by treating Ce(OH)CO3 templates with KMnO4 solution. Such formed Ce-MnOx nanotubes exhibit good catalytic activity in CO oxidation and adsorption performance in water treatment.

CTT Categories

- Basic Science

- Biomaterials & Medical

- Electronics

- Energy

- Glass

- Manufacturing

- Market Insights

- Thermal management