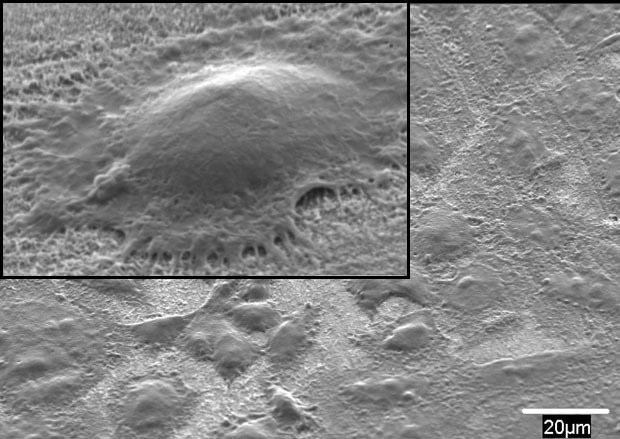

Researchers at The Ohio State University, Columbus, have developed a simple, affordable technique for creating oxide nanowires they say can improve cell growth by nearly 80 percent compared with other surfaces. (The transmission electron micrograph above shows cell growth 15 hours after placement on a nanowire-coated titanium alloy surface. Inset at upper left shows filaments reaching from cells to surface. Credit: S. Akbar/OSU.)

“What’s really exciting about this technique is that we don’t have to carve the nanowires from a solid piece of metal or alloy. We can grow them from scratch, by exploiting the physics and chemistry of the materials,” says Sheikh Akbar, professor of materials science and engineering, in a news release.

Scanning electron micrograph showing a single nanowire consisting of a titanium oxide core surrounded by aluminum oxide. OSU researchers created the material using a simple, inexpensive process. Credit: S. Akbar/OSU.

The research is described in a paper published in the July 2013 issue of the journal Ceramics International (DOI: 10.1016/j.ceramint.2012.12.004). According to the paper, the scientists grew the nanowires on a Ti-6Al-4V substrate that had been coated by thermal spray with titanium dioxide. The coated substrate was placed in an oxidizing atmosphere at 700°C for 8 hours. Fine TiO2 nanowires developed on the substrate, but the scientists are still working to explain the mechanism behind what happened next: Each nanowire grew a protective coating of aluminum oxide.

To test the bone growth capabilities of the wires, the researchers grew human osteosarcoma (bone cancer) cells on bare Ti-6-4, TiO2, and their nanostructured TiO2 substrates. Cancer cells were used because they reproduce in the same manner as healthy bone cells and are particularly hardy, according to the release. The researchers employed fluorescence microscopy and laser scanning cytometry to monitor cell proliferation on the three samples. They also monitored the alkaline phosphatase (ALP) activity of the cells at regular intervals.

According to the release, the researchers measured a 20 percent higher concentration of ALP produced by the cells growing on the nanowires in the first 15 hours of testing. By the end of the study, the nanowire substrate contained about 90,000 cells/cm2—80 percent more than the other two substrates.

According to study researcher Derek Hansford, associate professor of biomedical engineering and materials science and engineering, the nanowire coating could aid people who have hip and knee replacements, dental implants, or broken bones that require screws and plates for repair. “Our hope is that this surface treatment will become a simple-to-implement modification to titanium implants to help them form a stronger interface with surrounding bone tissue,” Hansford says in the release. “A stronger interface means that implants and bones will be better able to share mechanical loads, and we can better preserve healthy bone and soft tissue around the implant site.”

Akbar says $100 worth of metal foil is enough to make hundreds of samples using the process, and he stresses its simplicity. “The beauty is that the process is simple, inexpensive, and has mass-production capability (an entire surface of several square inches, for example, can be covered with nanostructures in a single step,” he says in an email.

The research team is now exploring other material and atmosphere combinations for biomedical and sensing applications.

Author

Jim Destfani

CTT Categories

- Biomaterials & Medical