[Image above] Credit: Pxfuel

I am getting to the age when doctors recommend I take a battery of tests to monitor my health. I’m not one who likes being poked and prodded, especially for a series of tests over the course of days or weeks. I can’t imagine having to continuously monitor blood chemistry or electrical activity as is the case for people with diabetes, heart conditions, and other diseases.

In the past few decades, implantable monitors took a giant leap forward. Perhaps you have seen the commercials of implanted diabetes monitors with Bluetooth that are read using cell phone apps. While these permanent implants are well-suited for life-long health monitoring, they are poor solutions for short-term conditions. If they were used for temporary monitoring, the patient would require a second surgery to remove the probes.

Glass science and engineering, specifically bioactive glass research, offers a potential solution in the form of bioresorbable glass sensors. These phosphate-based glasses are engineered to have the mechanical and optical properties necessary for handling, implantation, and operations in vivo, i.e., in living beings. The chemistry of these glasses enables them to safely dissolve in biological fluids after use due to the nontoxic compositions.

There is much to be learned about sensors made from bioresorbable phosphate glasses. The current issue of International Journal of Applied Glass Science contains twoarticles in which the properties and processing of materials for this unique application are explored.

Bioactive borophosphate fiber: Physical, chemical, and mechanical property changes

In the open-access article “Changes in the mechanical properties of bioactive borophosphate fiber when immersed in aqueous solutions,” researchers at Tampere University in Finland and Université de Rennes I in France observed and measured physical, chemical, and mechanical property changes in bioactive borophosphate fiber.

For their experiment, they fabricated two different types of calcium-strontium rich borophosphate glass fibers: a single-core fiber with a diameter of 125 µm, and a core-shell fiber with a diameter of 250 µm (the inner core was doped with ceria to change the index of refraction). They immersed the fibers in TRIS buffer and simulate body fluids at 37°C (the generally accepted normal human body temperature).

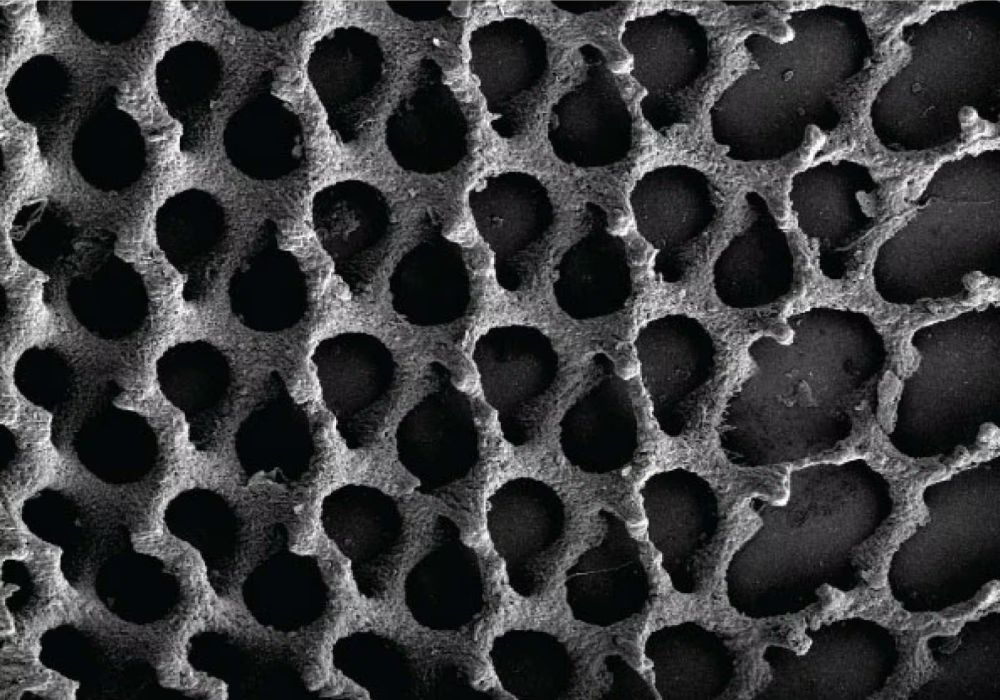

Chemical analyses along with measurements of fiber diameters indicated rapid dissolution rates upon immersion (within 3–7 days) followed by slower changes over the subsequent 3 weeks. Of particular interest, the measurements indicated that calcium/strontium phosphates precipitate on the surface of the fibers, which you can see in the images below. There were differences among the fiber diameters and immersion fluid, though composition (single versus core shell) showed minimal differences.

250 μm fiber before and after immersion in simulated body fluid for 2 weeks. Credit: Mishra et al., International Journal of Applied Glass Science (CC BY 4.0)

The mechanical properties of the fibers—specifically strength and Young’s modulus—are nominally constant within the range of uncertainty up to certain limits, and with some variations. The key finding is that the fibers maintain relatively high mechanical properties for several weeks of immersion. The substantive drops in mechanical properties coincide with formation of substantial calcium/strontium phosphate deposits. Again, there are differences due mainly to fiber diameter and immersion fluid but not fiber composition.

The authors conclude that since the composition of the fibers had minimal effect on the properties, particularly the mechanical properties, the core-shell design has promise for optical sensor fabrication.

The open-access paper, published in International Journal of Applied Glass Science, is “Changes in the mechanical properties of bioactive borophosphate fiber when immersed in aqueous solutions” (DOI: 10.1111/ijag.15514).

Manufacturing magnesium-rich borophosphate glass

While the above research group demonstrated feasibility of bioresorbable glass fibers for optical sensors, researchers from three Italy-based institutions—Politecnico di Torino, Università di Parma, and Fondazione LINKS—explored methods for manufacturing complex bioresorbable glass fibers for optical, gas, and fluidic sensors and therapies in their work in “Toward the fabrication of extruded microstructured bioresorbable phosphate glass optical fibers.”

In the introduction, they explain that motivation for their work comes from the fact conventional methods for producing preforms for complex tubular glass fibers, notably laser drilling and rotational molding, are not sufficient for bioactive glass compositions.

Their work centers around designing the die used to extrude precision tubes of their magnesium-rich borophosphate glass. Magnesium glass has both high mechanical properties and low refractive index, making it a good choice for sensor applications. Furthermore, for the purposes of die modeling and development, glass with high magnesium content has a small workability window (the difference between glass and crystallization temperatures) and is therefore a challenging test material.

The researchers used computational fluid dynamics and computer-aided design to design dies for extrusion. As is true with all modeling studies, the authors made assumptions and created boundary conditions according to known measurements and behaviors.

The image (right) compares the mechanical drawings to the computational fluid dynamics results and the actual extruded tubes for a test case of a preform containing two different diameter internal holes. The model shows insufficient glass flow for the left-side case, which is realized in practice. The right-side case shows substantially better results, though the authors admit their model needs further refinement to reduce the hole distortion.

Two-hole tube die mechanical drawings (A,B), computational flow models (C,D), and resulting actual tubes (E,F). Credit: Gallichi‐Nottiani et al., International Journal of Applied Glass Science

Using a less complicated die, the authors extruded single-hole tubes with inner and outer diameters of 8 mm and 10 mm, respectively, and usable lengths of approximately 100 mm. Some tubes were drawn down to a diameter of about 850 µm and cut to length. The smaller tubes were bundled into the larger tube and the entire package drawn down from an outer diameter of 10 mm to an outer diameter of 125 µm, producing several 10s of meters of usable fiber.

The paper, published in International Journal of Applied Glass Science, is “Toward the fabrication of extruded microstructured bioresorbable phosphate glass optical fibers” (DOI: 10.1111/ijag.14652).

Images of the end-view of the resulting fiber and infrared light transmission through the outer ring. Credit: Gallichi‐Nottiani et al., International Journal of Applied Glass Science

In summary, these two articles highlight the applied science and engineering that goes into taking bioactive glass technology from invention, synthesis, and materials characterization to process development, measurement, and scale-up required to manufacture devices and other products. Through this journal and its sister journals, ACerS leads the ceramics community in communicating scholarly knowledge of ceramic and glass materials throughout the entire product lifecycle and at all levels of research.

Update 10/21/2020 – Corrected to acknowledge that authors of the second paper come from three Italy-based institutions, including Fondazione LINKS

Author

Jonathon Foreman

CTT Categories

- Biomaterials & Medical

- Glass