A new development has been announced in the world of aerogel. ACS Nano published a paper on the process of developing and characterization of multi-walled carbon nanotube aerogel. The full text can be read for free here.

MWCNT aerogels have been hard to develop, largely due to the miniscule size of carbon nanotubes. Aerogels have typically been developed using silicon dioxide.

According to the paper, this new aerogel is fabricated from a wet gel of well-dispersed pristine MWCNTs. The researchers employed poly(3-(trimethoxysilyl) propyl methacrylate) as a dispersant and stabilizer, and also to encourage permanent chemical bonding the MWCNTs (chemical cross-linking was assisted with an ammonia aqueous solution). After removing the liquid component from the wet gel, researchers are left with MWCN aerogel.

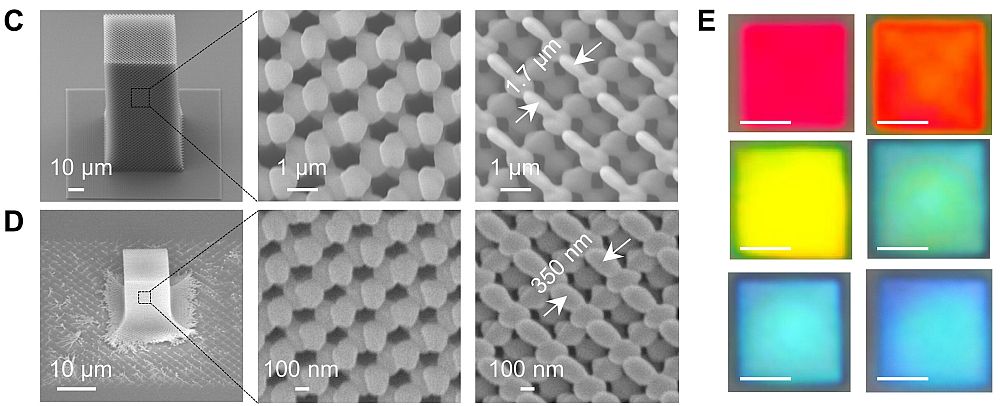

To optimize the final structure, the group sought something close to a honeycomb structure. They accomplished this during the wet-gel stage by using the controlled growth of ice rods via unidirectional freezing (the ice rods formed parallel to the freezing direction).

The resulting “honeycomb” structure separated by less than 100 nm-thick walls and a density of 4 mg/cm3. As the authors note, this “represents the lowest density ever for free-standing monolithic CNT aerogel, and is only slightly larger than the lowest recorded aerogel density in literature (3 mg/cm3)”.

The University of Central Florida researchers at the NanoScience Technology Center, including Jianhua Zou, Jianhua Liu, Ajay Singh Karakoti, Amit Kumar, Daeha Joung, Qiang Li, Saiful I. Khondaker, Sudipta Seal and Lei Zhai, also discovered that the honeycomb walls of entangled MWCNTs had a with a surface area of 580 m2/g.

So what can this material do? For starters, despite its ultralow density, the group says the MWCNT aerogel has an excellent compression recoverable property, as well as an electrical conductivity of 3.2 × 10−2 S/cm (which can be permanently increased to 0.67 S/cm by a high-current pulse).

This video recorded at Zai’s laboratory at the NanoScience Technology Center (University of Central Florida) demonstrates the compression strength and recoverability of the aerogel. It can be repeatedly compressed down to 5 percent of its original volume and the recover most of its original volume, due to the anisotropic structure of the material and the cross-linking between MWCNTs. When the compressing stress is applied to the aerogel, the MWCNTs tend to be bent instead of slipping past each other. Consequently, the strain energy is stored within the MWCNT aerogel; volume recovery is driven by the release of the strain energy.

This compression and conductivity of the aerogel gives it valuable pressure-response properties: electrical resistance varies with pressure. They measured is a linear drop in resistance from as low as 5 Pa to 180 Pa. (Above 180 Pa, little change occurs.) This effect is reproducible with resistance changes occurring .2-.4 seconds after pressuring loading/unloading. As the authors note, this makes the MWCNT aerogel a “promising” candidate for pressure sensing.

Vapor sensing is another potential application for the material. For example, in the lab, the response of the MWCNT aerogels response to chloroform vapor was investigated. With just a .5 second exposure to chloroform, the resistance of the MWCNT aerogel spiked, and within .5 second of exposure to air, the resistance returned to its prior level. This response occurred with vapor concentration levels as low as 1 ppb. This is attributed to the material’s unique hierarchical porous structure.

Assembling the MWCNT aerogel into bulk materials will open new doors in material developments and applications. Besides uses in sensors to detect pollutants and toxic substances, chemical reactors and electronics components, the authors foresee it being a good candidate for catalyst supports and novel electrodes.

CTT Categories

- Material Innovations

- Nanomaterials