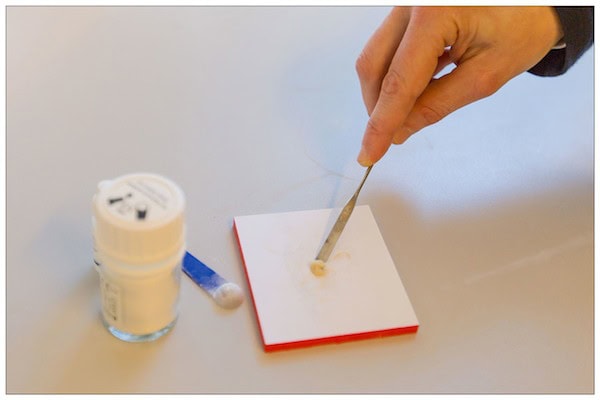

[Image above] Glass ionomer cement is a promising material for dental fillings because it can be mixed easily by hand, sparing the need for special mixing equipment. Credit: University of Copenhagen

According to the most recent National Health and Nutrition Examination Survey, conducted by the National Institutes of Health from 1999–2004, 92% of American adults (20–64 years old) have had cavities in their permanent teeth. And each of those individuals have an average of 4.61 filled teeth.

By my back-of-the-envelope calculations, that’s somewhere in the neighborhood of 1 billion dental fillings—1 billion!

That slew of fillings are accomplished by a variety of materials of choice, each with its own list of pros and cons.

Traditional metal fillings—gold or an amalgam of mercury, silver, tin, and copper—are reliable and hold up well, but they are highly noticeable. And there are concerns over the environmental impacts of amalgam’s primary ingredient, mercury.

Composite fillings, instead, are cheaper and can be matched to tooth color for a more inconspicuous choice, but composite fillings don’t last as long.

Another option is glass ionomer cement, which adheres to teeth better and so doesn’t require bonding agents. But, it’s also not as strong and durable and is usually not recommended for higher load-bearing teeth, such as molars.

So, better materials are still needed.

Researchers at the University of Copenhagen, along with colleagues at various other European institutions, are not only advocating on behalf of glass ionomer cement’s benefits, but they’re also researching ways to make the material even better for dental work.

“Glass ionomer cement has the advantage that it does not need an intermediate layer of adhesive to bond to the tooth and it also has the interesting property in that it releases fluoride, which of course help to prevent cavities. The material also has good biological properties, while it is almost as strong. Our research therefore focuses on understanding the connection between the microstructure of the material and its strength in order to improve its properties,” says Ana Benetti, dentist and researcher at the University of Copenhagen, in a university press release about the work.

Heloisa Bordallo, right, and Ana Benetti work on a strong material for tooth fillings made out of glass ionomer cement. Credit: University of Copenhagen

Part of the beauty of the glass ionomer cement, in comparison to metal or composite fillings, is that pulverized glass can simply be mixed with water by hand to create the cement, bypassing the need for special mixing equipment. It also doesn’t require UV illumination to harden, like composites do, making it an easier and cheaper option, especially in remote or ill-supplied areas.

The researchers investigated the effect of adding acid to the water to hydrate the cement, to see if that small change could improve the fillings’ strength. To see how the acid–water mix fared against water alone, the team studied the properties of the cement by itself and when used in mock fillings in extracted teeth.

“First, we took X-rays of the teeth with the cement fillings. They show the structure of the material. Glass ionomer cement is porous and you can get an accurate image in 3-D, which shows the microstructure,” explains Heloisa Bordallo, associate professor and materials researcher at the Niels Bohr Institute at the University of Copenhagen, in the release.

They also used neutron scattering to assess whether there was liquid in the pores of the material, which would negatively impact its strength and ability to prevent breaking.

The team repeated the analysis over several days as the material hardened to see how liquid was moving around within the materials’ pores, an important parameter to determine how well it would hold up over time in an actual patient’s mouth.

The results revealed an unexpected importance to the order of operation for combining ingredients.

Researcher Ana Benetti mixes up glass ionomer cement by hand in the lab. Credit: University of Copenhagen

“Experiments showed that the combination where the acid is mixed up in the cement, so you only have to add water to the cement powder is the weakest material. You get the strongest material by having cement powder mixed with water that has had acid added to it. So it is better to have the acid in the water—it helps to bind the liquid faster and stronger to the cement and there is less water in the pores,” Bordallo says in the release.

Although the results represent advanced understanding for the material, it isn’t quite ready to replace more standard composite or metal fillings. But, according to the release, the team is now working on new glass ionomer mixtures with additional natural minerals in the cement to try to get even less liquid in the pores.

Those changes could further improve the strength and durability of glass ionomer cement to make it a material of choice for the future of billions of dental procedures.

The paper, published in Scientific Reports, is “How mobile are protons in the structure of dental glass ionomer cements?” (DOI: 10.1038/srep08972).

Author

April Gocha

CTT Categories

- Biomaterials & Medical

- Cement

- Glass

- Material Innovations