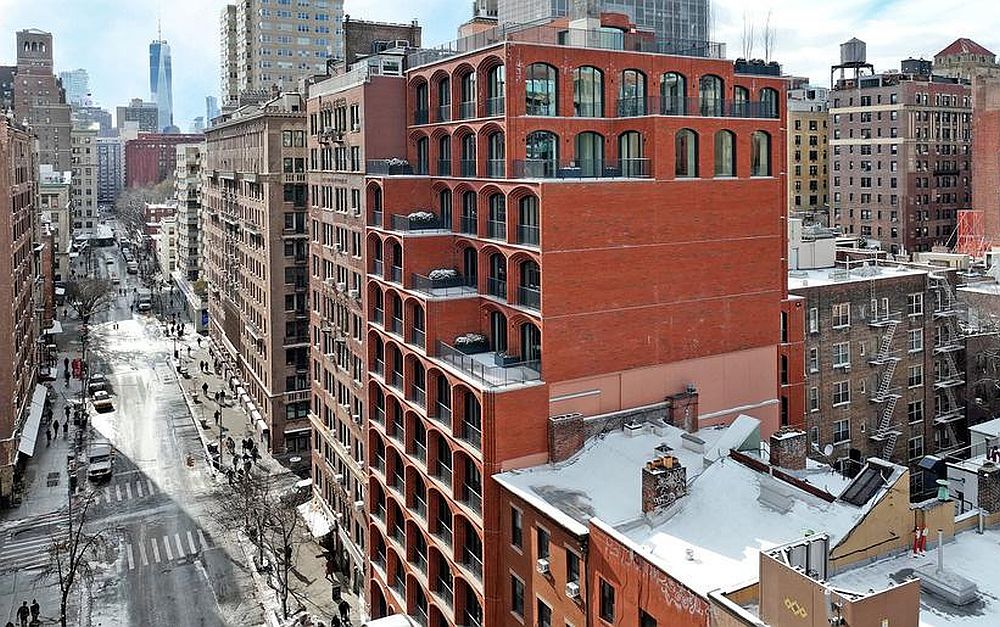

[Image above] The Sandelford Bridge, a box girder bridge in Coleraine, Northern Ireland. The cross sections of prestressed concrete box girders are typically subjected to bending and eccentric compression forces during application. Developing a model that accurately simulates long-term creep behavior due to these forces is important for bridge safety. Credit: Albert Bridge (CC BY-SA 2.0)

There is only one thing worse than pulling your clothes out of the washer and realizing you forgot to empty pockets—pulling a soft, comfy cotton sweater from the dryer and realizing it was not preshrunk.

Today, many cotton shirts are sold preshrunk to avoid the grief that comes from finding your favorite new shirt shrunk a size too small. However, my dad always cautioned that preshrunk cotton does not mean the shirt will never shrink—it is still best to hang or tumble dry such clothing.

The textile industry is not the only industry that proactively counters material changes expected in application. Construction workers often prestress concrete to strengthen it against tensile forces that occur during service, which can cause concrete creep (deformation under sustained load).

But just as a preshrunk cotton shirt can still shrink in future washing, prestressed concrete can still crack under stress.

In particular, many prestressed concrete bridges are reported to suffer from excessive vertical deflections and cracking due to eccentric compression forces, i.e., forces that are nonsymmetric to the central axis, thereby producing a bending motion along with axial stress. While existing design guidelines can calculate time-dependent vertical deflections, “actual measured deflection usually exceed the calculations due to the inaccuracy of existing creep and shrinkage models,” researchers write in a recent paper.

The researchers come from the University of Warwick and University of Sheffield in the United Kingdom as well as Chongqing Jiao Tong University in China. They explain that existing state-of-the-art guidelines such as Model Code 2010 (MC2010), the most comprehensive code on concrete structures, assume compressive and tensile creep are identical. “However, recent experimental evidence indicates that the tensile creep strains can be between 2.4 and 8.9 larger than the compressive creep strains,” they write.

That difference is attributed to microcracking and drying-induced microprestressing, concrete elements that are affected significantly differently based on the applied force. For example, compressive forces tend to close microcracks, whereas tensile forces promote growth and widening of microcracks.

These drying-induced damages are not properly accounted for in existing creep damage models. So the researchers of the recent study proposed modifying the MC2010 creep damage model by combining it with an isotropic elastic damage model proposed by Mazar, which allowed them to account for drying-induced damages.

To validate their model, the researchers simulated the long-term behavior of two simple-supported reinforced concrete beams, which were previously investigated experimentally in another study. Then, the modified model results were compared with results obtained using the original MC2010 shrinkage and creep models.

“It is shown that the proposed approach predictions match well the experimental beam deflections for both the instantaneous deflection and time-dependent deflection,” the researchers write. “This confirms the importance of considering the drying-induced stress in the analysis of long-term deformations of concrete elements.”

In contrast, “MC2010 matches well the cracks in the constant moment region (due to the first loading), but not the cracks outside this region that developed during the period of sustained loads.”

Comparison of calculated specific creep under compression and tension for stress/strength ratio = 50%. The total creep (basic creep plus drying creep) results show that the specific creep strain in tension is significantly higher than in compression. When the ratios of basic creep and total creep between tension and compression are compared, the results indicate that the difference between these creeps can be attributed to drying-induced damage. Credit: Huang et al., Materials and Structures (CC BY 4.0)

In the conclusion, the researchers recommend use of their model but note several avenues for future study, including gathering more data to further generalize the model, investigating use of an elastic–plastic damage criterion instead, and considering additional drying due to surface damage.

The open-access paper, published in Materials and Structures, is “A practical creep model for concrete elements under eccentric compression” (DOI: 10.1617/s11527-019-1432-z).

Author

Lisa McDonald

CTT Categories

- Cement

- Construction

- Modeling & Simulation