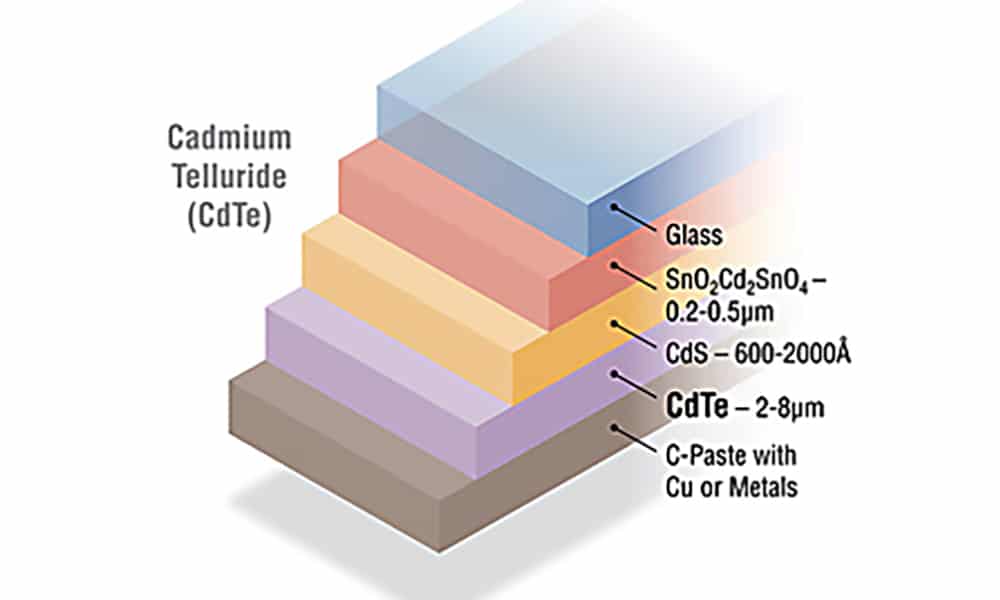

[Image above] An illustration of the layers that make up a cadmium telluride solar cell. Credit: National Renewable Energy Laboratory

In terms of both cumulative and annual installations, the United States is the second-largest photovoltaic market in the world. But despite being a leading PV market, the U.S. “is below the global average and other leading markets in terms of PV generation as a percentage of total country electricity generation, with 5%,” the National Renewable Energy Laboratory (NREL) reports in its latest Quarterly Solar Industry Update.

Numerous initiatives and incentive programs at both the federal and state levels aim to improve this statistic. Today we look at one maturing solar technology that is gaining momentum—cadmium telluride (CdTe) solar cells.

What are cadmium telluride solar cells?

CdTe solar cells are one of the four major types of thin-film solar technologies. In contrast to conventional crystalline silicon solar panels, which consist of wafers that are hundreds of micrometers thick, the active layers of CdTe solar cells are just a few micrometers thick. This design allows CdTe solar cells to be produced at lower costs and with simpler production processes.

Research on cadmium telluride for solar applications dates to the 1950s, but the first commercial production of CdTe solar cells took place in 2002 in Perrysburg, Ohio. First Solar, the company that produced these first cells, remains a prominent manufacturer of CdTe solar cells today.

CdTe solar cells are now the second most common photovoltaic technology globally after crystalline silicon. That is a very distant second, however—it represents 5% of the world market, in contrast to silicon’s 95%.

This disparity is due to the fact cadmium telluride, despite having a higher theoretical efficiency level than silicon, has yet to realize its potential. The estimated theoretical efficiency of CdTe solar cells is about 30%, but the current record efficiency is 22.1%. As of 2020, the average commercial module efficiency is only about 18%, in contrast to silicon’s 18–22% average efficiency.

Learn more about CdTe solar technology in the video below.

Credit: DelftX Solar, YouTube

Consortium aims to accelerate development of CdTe technologies

In August 2022, the U.S. Department of Energy announced the launch of the Cadmium Telluride Accelerator Consortium. This $20 million initiative, which will be administered by the National Renewable Energy Laboratory (NREL), aims to make CdTe solar cells less expensive and more efficient while also developing new markets for CdTe solar cell products. It will ideally enable cell efficiencies of more than 24% by 2025 and more than 26% by 2030, according to an NREL press release.

NREL released a “request for proposals” notice in September 2022 to identify projects that would support the consortium’s goals. On June 22, 2023, NREL announced it had awarded $2 million to fund six projects. A full description of each project is available at this link, but in brief, the six projects are

Topic area 1: High-efficiency devices

- The University of Utah will develop sputtered, doped widegap materials and bilayer stacks for back contacts to state-of-the-art CdSeTe/CdTe absorbers.

- The University of Delaware will develop new approaches for processing Cd1–xZnxTe solar cells that overcome previously reported difficulties, such as ineffective chloride activation and passivation, which prevented the realization of high performance with increased open-circuit voltage relative to CdTe.

- The University of South Florida will develop alternative device architectures based on n-type CdTe/CdSexTe1–x(CST) thin-film absorbers to create opportunities to overcome the efficiency limitations associated with the current state-of-the-art p-type CdTe/CST solar cells.

Topic area 2: Tellurium supply

- Missouri University of Science and Technology will enhance tellurium recovery from copper processing by optimizing the current operations to capture the tellurium, gold, and silver that are presently lost to tails.

Topic area 3: Characterization, modeling, and simulation

- Arizona State University will combine the power of hard X-ray microscopy and soft X-ray and electron spectroscopies to probe arsenic-doped CdSeTe absorbers and devices.

- The University of Utah will assess the role of microstructures in advanced CdTe devices.

CdTe manufacturing expands in Ohio

As mentioned earlier, Arizona-based First Solar remains a prominent manufacturer of CdTe solar cells. An open-access article published in Energy News Network details how the company—along with another Ohio-based CdTe manufacturer—recently announced major expansions.

The article reports that First Solar plans to open a third Ohio factory later this year in Lake Township. This 3.3-gigawatt plant will be followed by a 1.3-million-square-foot research and development facility in Perrysburg, slated to open in 2024. The company is also planning to open a fourth U.S. factory in Alabama in 2025, bringing the company’s total U.S. production capacity to roughly 10 GW.

Meanwhile, Toledo Solar, which just started production in 2021, is tripling its production capacity from 100 to 300 megawatts this year. The company, which targets the commercial- and residential-scale market, is much smaller than First Solar, which targets the utility-scale market. Regardless, this expansion is “a big deal for us,” says Toledo Solar CEO Aaron Bates in the Energy News Network article.

Toledo Solar’s plans may be complicated, however, by a recent legal complaint filed against the company by First Solar. The complaint alleges that Toledo Solar passed off First Solar panels as its own.

Author

Lisa McDonald

CTT Categories

- Energy

- Material Innovations