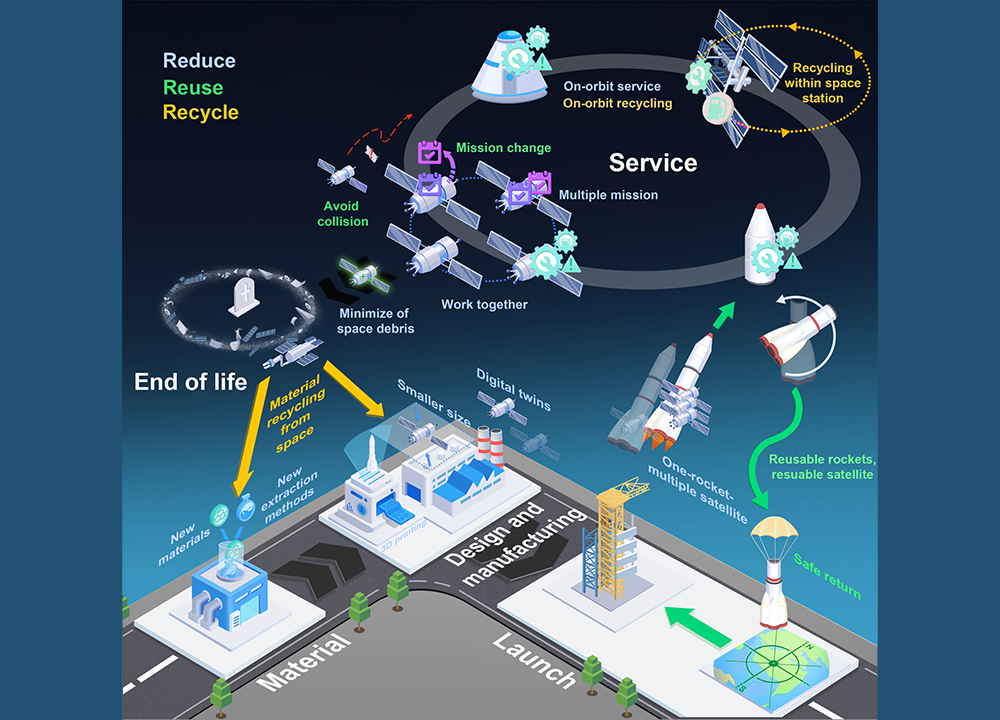

[Image above] Credit: Daniel K. Inouye Solar Telescope (CC BY 4.0)

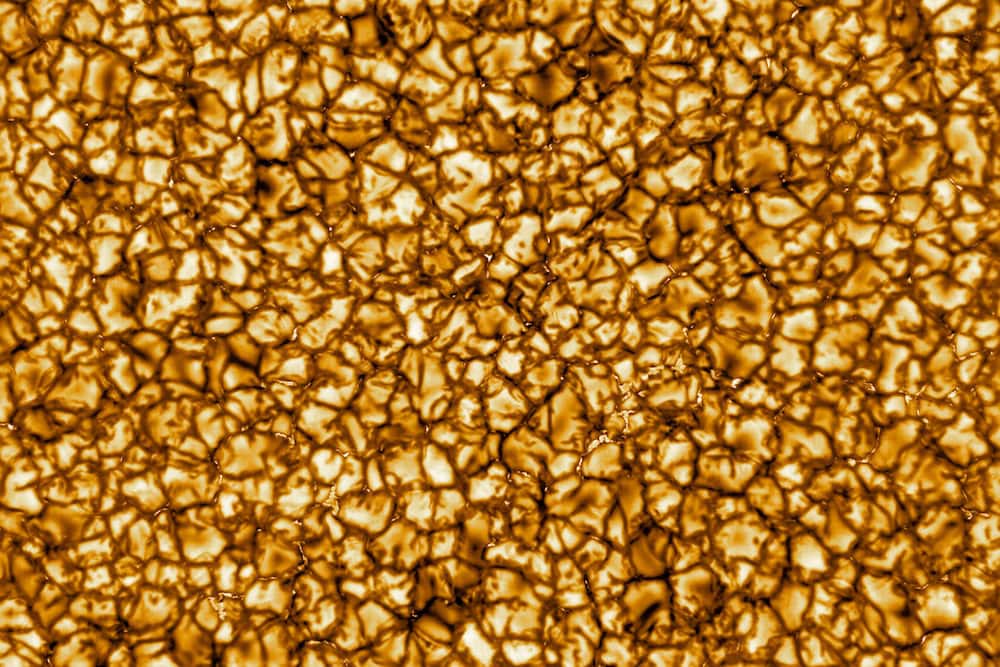

From almost 93 million miles away, our sun looks like a smooth yellow orb. But when looked at up close using powerful telescopes, you realize the sun is a very lively place full of turbulent gas, magnetic storms, and thermonuclear reactions—which, taken together, look a lot like a giant boiling pot of caramelized popcorn.

Credit: National Solar Observatory, YouTube

The popcorn-like similarity was pointed out by multiple news outlets covering release of the first-ever images from the National Science Foundation’s Daniel K. Inouye Solar Telescope (DKIST). The images reveal unprecedented detail of the sun’s surface and preview the data that is expected to come from DKIST once construction of the observatory is completed by June 2020.

DKIST: World’s largest solar telescope

Located on the island of Maui, Hawaii, DKIST is the largest solar telescope in the world. Its monolithic 4.26-meter (13.9-foot) primary mirror outdoes the previously largest solar telescope, McMath-Pierce Solar Telescope, by quite a bit—McMath-Pierce’s primary mirror is only 1.6 meters (5.25 feet) in diameter.

In the first released images from DKIST, there are several eye-opening statistics to mention, including the fact that each cell-like structure is about the size of Texas. Yet many news outlets did not mention a particular bit of information exciting to materials scientists—the imaging quality of DKIST is made possible by glass-ceramics.

ZERODUR: Astronomy’s go-to glass-ceramic

The large primary mirror in DKIST was manufactured by Schott AG in Germany using their trademarked glass-ceramic ZERODUR, a nonporous lithium aluminum silicon oxide glass-ceramic with extremely low thermal expansion.

A review article on ZERODUR by Schott AG scientists describes why the glass-ceramic has such low thermal expansion.

“It owes approximately 70 to 78 percent of its weight to nano-crystallites of 30 nm to 50 nm in size, embedded in a remaining glassy phase,” the authors write. “Size and number of the nano-crystallites are adjusted to achieve an extremely low thermal expansion.”

Since Schott AG first produced ZERODUR for the Max-Planck-Institute in 1968, numerous large-scale telescope projects around the globe used this glass-ceramic for their mirrors, including the ESO Very Large Telescope in Chile, Gran Telescopio Canarias in Spain, Keck Observatory telescopes in Hawaii, and flying NASA telescope SOFIA.

ZERODUR also will be used for mirrors in the ESO Extremely Large Telescope (ELT) being built in Chile, which is targeted to achieve first light in 2025. In the video below, see how the glass-ceramic is made and learn about the different mirrors that will be made from it for ELT.

Credit: SCHOTTcom, YouTube

Author

Lisa McDonald

CTT Categories

- Aeronautics & Space

- Optics