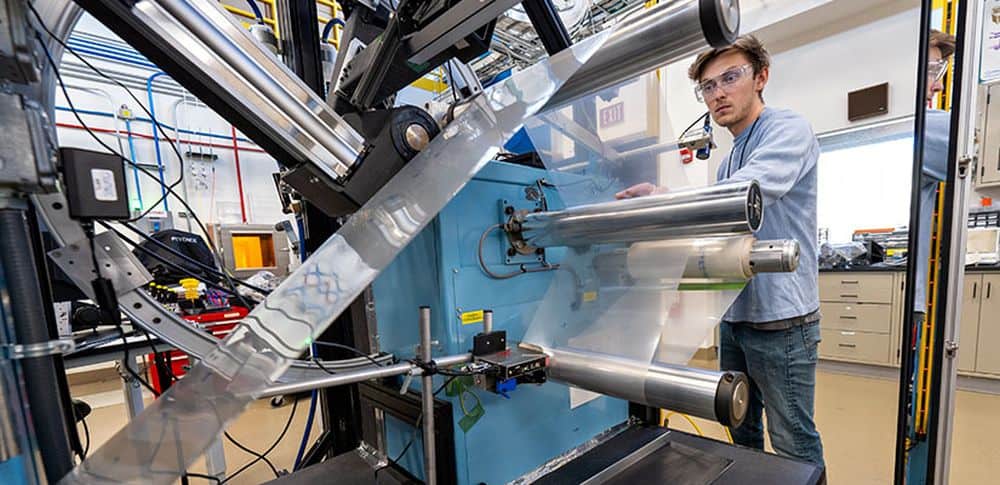

[Image above] The National Renewable Energy Laboratory’s roll-to-roll web line is used for research of in-line quality control monitoring techniques for battery, electrolyzer, and fuel cell materials. Credit: Werner Slocum, NREL

Research on hydrogen technologies really fired up in the last year, with companies around the world testing the potential of this alternative fuel. But even as these tests yield promising results, upscaling this technology so it can be adopted by industry faces many challenges along the entire supply chain, from production and storage to transport and use.

The U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) has led efforts in the United States to address these challenges. For example, the HydroGEN Advanced Water Splitting Materials Consortium, launched in 2016, advances the scientific understanding of hydrogen production through electrolysis (water splitting). The H2NEW Consortium, launched in 2020, aims to identify the materials and manufacturing processes that will enable production of affordable and durable electrolyzers.

In October 2023, NREL scientists Huyen N. Dinh and Bryan Pivovar presented an update on these consortiums at the Research and Development 20 Conference in Japan. Their report demonstrated the success of these consortiums in advancing hydrogen technology.

With the science and tools for hydrogen production validated, the next step is a transition to mass manufacturing of hydrogen technologies. This step will be tackled by the new Roll-to-Roll (R2R) Consortium, which NREL announced on March 25, 2024.

The R2R Consortium consists of NREL, Argonne National Laboratory, Oak Ridge National Laboratory, Lawrence Berkeley National Laboratory, and Sandia National Laboratories. The laboratories plan to use roll-to-roll processing to enable high-throughput manufacturing of hydrogen fuel cells and water electrolyzers.

Roll-to-roll processing is a fabrication method that embeds, coats, prints, or laminates varying applications onto a flexible rolled substrate material as that material is fed continuously from one roller on to another. The video below by Oak Ridge National Laboratory shows how roll-to-roll processing works.

Credit: Oak Ridge National Laboratory, YouTube

Roll-to-roll processing has the potential to increase efficiency, reduce waste, and improve the cost of hydrogen technology production. But there are challenges related to materials synthesis, coating, drying, and quality control that must be addressed to scale the process for industry adoption.

“The consortium’s activities will focus on understanding the science of the manufacturing processes themselves to achieve target rates, yields, and product quality,” says Scott Mauger, R2R Consortium director and senior scientist at NREL, in the NREL press release.

In addition to conducting internal research at the laboratories, the R2R Consortium plans to support industry efforts through cooperative research and development agreement projects. More details regarding this aspect of the consortium will be announced in the coming months.

Author

Lisa McDonald

CTT Categories

- Energy

- Manufacturing