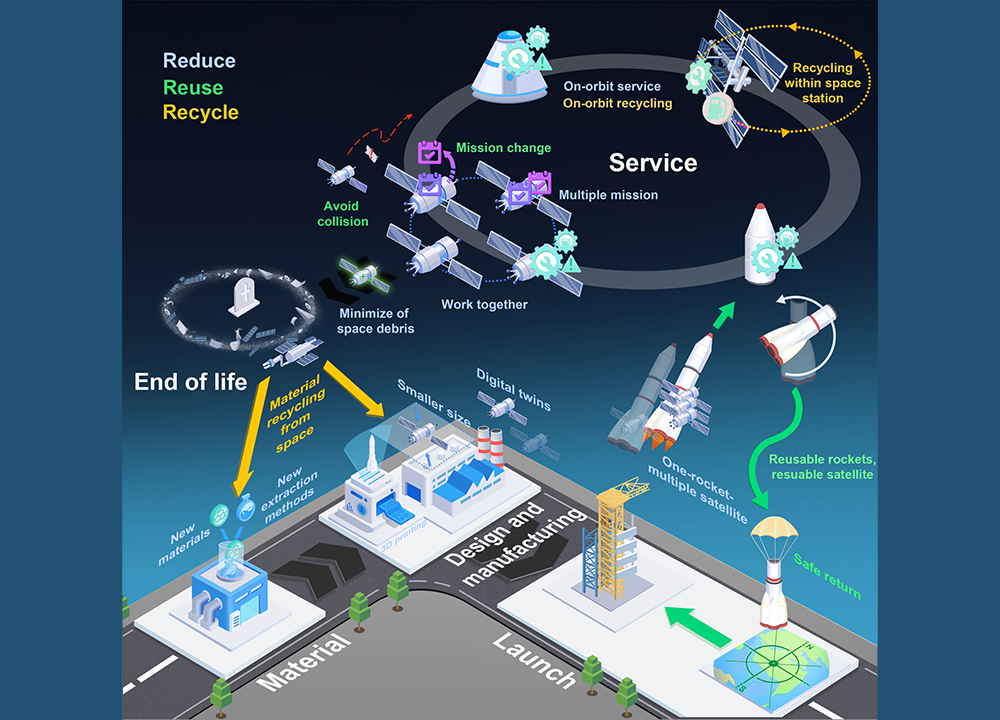

[Image above] Lamborghini and the Houston Methodist Research Institute are collaborating on a six-month project to test carbon fiber composites in extreme space environments. Credit: Lamborghini, YouTube

You know what would be a fun job? Being a vehicle test technician. Sure, there are likely many days when you spend hours determining why the “check engine” light refuses to turn off. But then there are days when your job is a “smashing” success.

Credit: Freeze Lists, YouTube

Crash testing is an important part of vehicle testing to ensure safe design standards. There are countless videos online illustrating the results of frontal-impact, side-impact, and roll-over collisions. Yet these impressively destructive tests are a culmination of many smaller tests on specific materials and components.

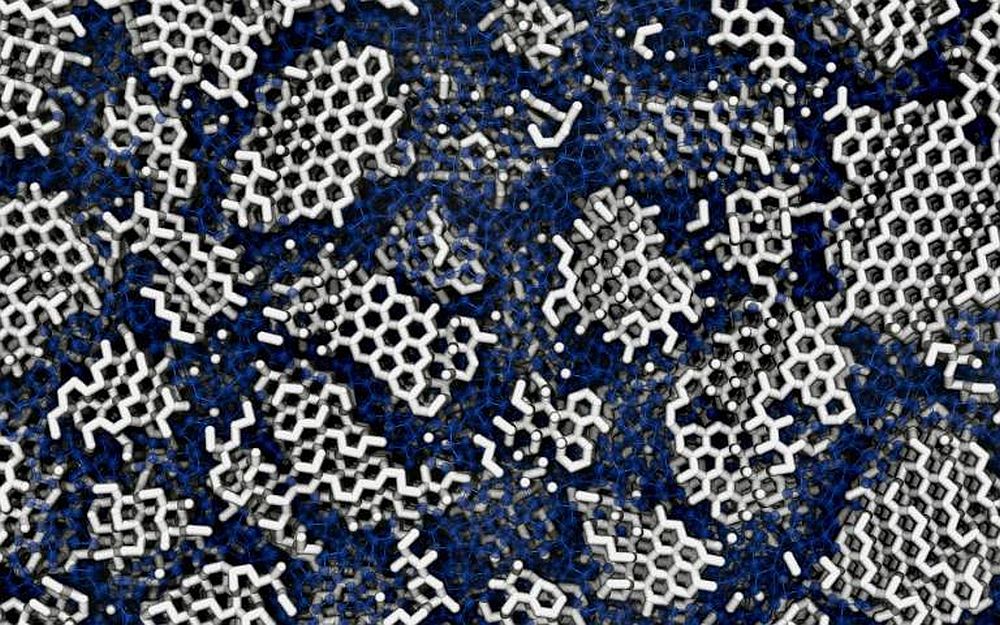

Before becoming part of a car, potential materials are thoroughly tested, including glass, metals, plastics, and carbon fiber.

Carbon fiber is widely used in a variety of products, from aircraft and automotive components to phone cases and even guitars. When combined with a polymer, carbon fiber can be molded into car parts that are stronger and lighter than comparable steel and aluminum parts.

Safety-critical carbon fiber parts, such as car frames, go through a litany of tests before inclusion in a final product, including destructive tests (e.g., stress fatigue) and nondestructive tests (e.g., fiber orientation, delamination, and bonding). This month, Lamborghini plans to test carbon fibers in a new way—in outer space.

Blastoff to testing in 3, 2, 1…

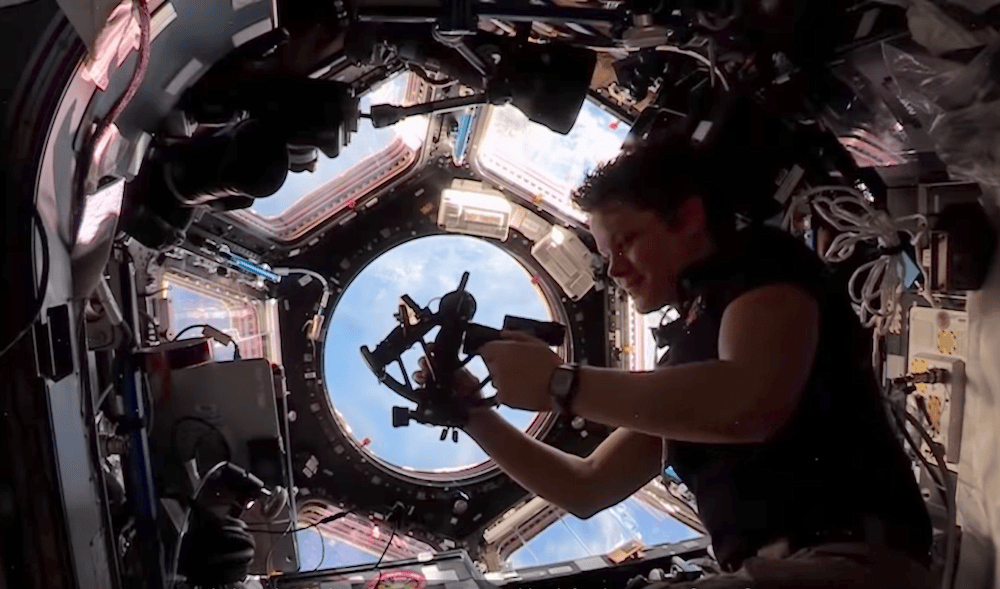

On November 2, Lamborghini sent five samples of carbon fiber composites to the International Space Station (ISS). According to Stefano Domenicali, CEO of Lamborghini, “Lamborghini is the first automaker in the world to send components developed and produced in-house to the ISS for scientific purposes,” he says on the Lamborghini website.

The samples, developed at Lamborghini’s materials lab in Italy, were created using various techniques, including 3D printing, pre-impregnated epoxy resin, and autoclaved polymer fabric. The samples will be on the ISS for six months, and they will be subjected to temperatures ranging from -40°C to 200°C as well as ultraviolet radiation and gamma rays.

The project is the result of an agreement Lamborghini signed with the Houston Methodist Research Institute in 2017 to jointly research the biocompatibility of composite materials. Particularly, the joint research project focuses on determining possible use of the composite materials in prosthetic implants and in subcutaneous devices, taking advantage of the materials’ light weight, radio transparency, and radio compatibility.

Learn more about the planned project in the video below.

Interested in what other projects are taking place on the ISS? Check out this list of experiments.

Credit: Lamborghini, YouTube

Author

Lisa McDonald

CTT Categories

- Aeronautics & Space