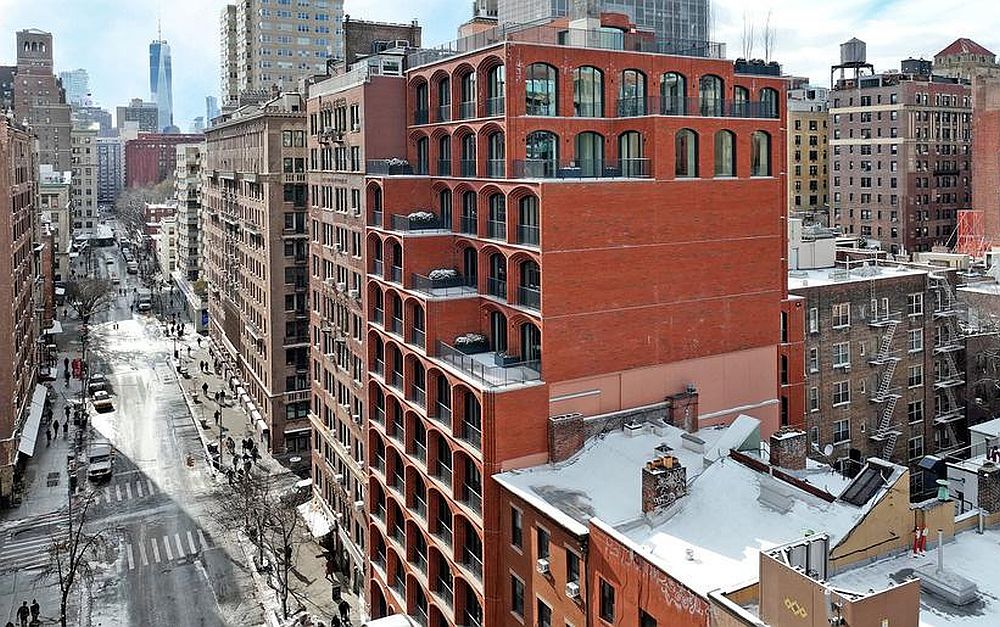

[Image above] Fiber cement is an increasingly popular material for house siding. How does it compare to other siding materials, and how is it made? Credit: How Its Made, YouTube

With so much media focus on the upcoming decennial population census, it can be easy to forget the United States Census Bureau conducts many other surveys as well. I decided to see what other statistics the Census Bureau stores on its website, and that search led me to a survey that prominently features ceramics and ceramic composites—the Survey of Construction.

The Survey of Construction provides national and regional statistics on starts, completions, and characteristics of new, privately-owned single-family and multifamily housing units and on sales of new single-family houses. Data is available on a monthly and annual basis and includes information on major materials used in house construction.

When it comes to materials used for primary exterior walls, vinyl holds first place with 26% of the market, followed closely by stucco at 25%. (The Great Recession in the late 2010s witnessed a dip in stucco sales and a rise in vinyl, but stucco gained steadily on vinyl ever since.) Third place belongs to brick at 21%, but fourth place (20%) may surprise those unfamiliar with housing materials—fiber cement.

Fiber cement is a relatively new siding material introduced to the market about 35 years ago. Austrian Ludwig Hatschek patented the original fiber cement in 1901 under the name “Eternit,” which consisted of cement mixed with asbestos fibers. But as the health risks of asbestos exposure became widespread knowledge in the 1970s, the U.S. government passed legislation limiting asbestos. So in the mid-1980s, building materials company James Hardie developed a new formulation of fiber cement that replaced asbestos fibers with wood pulp.

The Survey of Construction shows fiber cement siding grew from 9% to 20% of the U.S. new single-family house market during 2005–2018. The fiber cement market is expected to grow at a CAGR of more than 5% between 2019–2024, but the threat of substitutes like vinyl and wood siding is expected to hinder growth.

Wood and vinyl—comparison of fiber cement to its “threats”

Fiber cement siding offers several advantages to wood, the last-place material in the Survey of Construction with only 5% of the market. Advantages include

- Insect resistance,

- Better return-on-investment [84% versus 77% (natural wood) or 79% (engineered)], and

- Similar pricing for full house cladding [$15,000–$25,000 versus $14,000–$25,000 (natural wood)].

Fiber cement could potentially cost similar to engineered wood ($10,000–$18,000) if self-installed, as most of the cost is due to a labor-intensive installation process. However, DIY fiber cement installation is not recommended, as fiber cement is a very heavy material and benefits significantly from expert installation. Additionally, wood has a higher R-value than fiber cement (0.80–1.35 versus 0.50), which makes it a better thermal insulator.

Fiber cement also has a better return-on-investment next to hollow-back (81%) and foam-back (77%) vinyl, but it cannot compete in cost to hollow-back ($6,000–$12,000). Also, because vinyl is a lightweight material, it is easier to remove and replace compared to fiber cement. On the other hand, fiber cement can last 100 years when properly cared for, whereas vinyl lasts 20–40 years. In terms of R-values, both hollow-back and foam-back vinyl are higher than cement fiber: hollow-back ranges 0.6–1.0 and foam-back ranges 2.0–5.0.

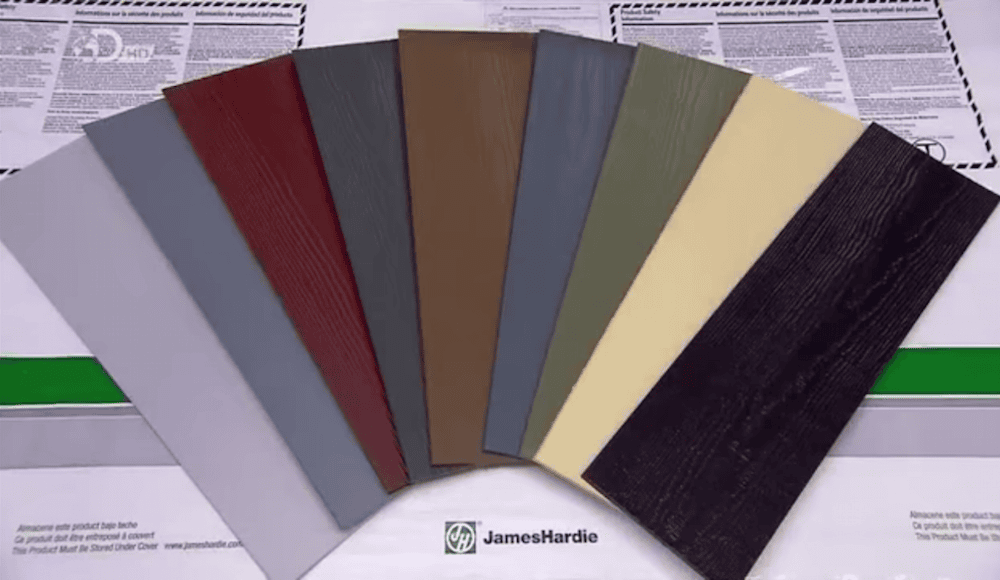

Fiber cement: Chameleon of the architect world

A unique thing about fiber cement siding is its design—when detailed properly, it can mimic the look of wood, brick, cement, and stone. In fact, fiber cement replicates the look of other materials so well it is accepted for use in some historic districts!

For fiber cement design examples, check out the product page of fiber cement company Nichiha, which offers different styles and finishes mimicking a multitude of raw materials.

Example of a Shera Plank, a brand of fiber cement planks designed to look like wood. Credit: Stitus Shera planks, YouTube

How fiber cement siding is made

So how is this increasingly popular material produced? The highly rated television show “How It’s Made” featured fiber cement in season 18, and the clip is available on YouTube for your viewing pleasure.

Credit: Panos Egglezos, YouTube

Interested in the role ceramic and glass materials play in construction? Keep your eyes out for the December issue of the ACerS Bulletin—its cover story will highlight ceramic and glass materials used in residential homes!

Author

Lisa McDonald

CTT Categories

- Cement

- Construction