CoorsTek announces opening of new ceramic proppants manufacturing plant

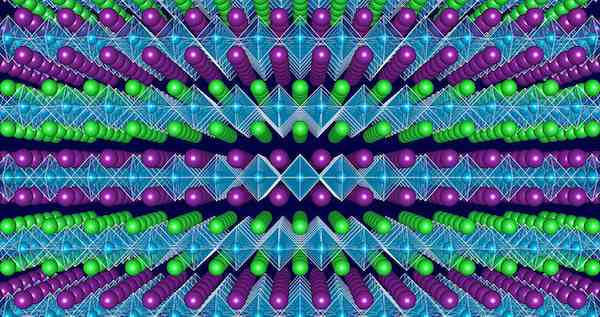

CoorsTek, Inc., announced the opening of a new plant in the Coors Technology Center in Golden, Colorado producing premium lightweight ceramic proppants. The new plant uses state-of-the-art manufacturing equipment and has received all regulatory approvals including air permits. Proppants are sand-sized solid materials used to keep induced hydraulic fractures open allowing oil and gas to flow. Many low-performance offerings are treated sand while high-performance options are made from ceramics. CoorsTek CeraProp ceramic proppants exhibit one of the highest crush strengths in the lightweight ceramic proppant market. Initially, CoorsTek offers lightweight proppants in 16-30, 20-40, 30-50 and 40-70 mesh sizes and custom-developed, customer-specific proppants.

PPG earns DOE funding to develop dynamically responsive IR window coating

PPG Industries’ flat glass business has received $312,000 from the US Department of Energy to develop a dynamically responsive infrared window coating that will block heat in the summer to reduce air-conditioning costs and transmit solar heat in the winter to reduce heating costs. The funding is part of an award of up to $750,000 being shared with project leader Pacific Northwest National Laboratory. PPG and PNNL are designing a coating that can “switch” from a solar IR-reflecting state to a solar IR-transmitting state while maintaining high levels of daylight transmittance in either condition. The development of such a coating would represent a major advance compared to current thermochromic window technology, which involves coatings that darken and block visible light when exposed to high volumes of IR energy, and existing electrochromic window technology, which relies on external power sources such as electricity to balance tinting and light transmittance.

Acacia Research Corporation announced that an Acacia subsidiary has partnered with a leading research institute to monetize the institute’s patents relating to ceramics and associated manufacturing processes for medical devices. The research institute will share in the royalties Acacia generates from licensing the patents. “Acacia continues to increase the number of leading patent portfolios in the medical device and life sciences space,” commented Matt Vella, CEO. “Ceramics are utilized in a wide range of medical devices, including orthopedic, dental and ultrasound applications.”

GrafTech reports losses for fourth quarter, full year

(Crain’s Cleveland Business) GrafTech International Ltd., which faces the prospect of a proxy fight for control of its board of directors, has reported losses for the fourth quarter and full year compared with year-earlier profits in both periods. The Ohio-based producer of graphite electrodes and other carbon-based products said its net loss in the fourth quarter totaled $28 million, or 21 cents per diluted share. In the fourth quarter of 2012, GrafTech earned $29 million, or 21 cents a share. Sales in the quarter fell 17%, to $309 million from $371 million. For all of 2013, GrafTech lost $27 million, or 20 cents a share, a big decline from earnings of $118 million, or 84 cents a share, in all of 2012. Sales declined 7%, to $1.17 billion from $1.25 billion.

New VeroGlaze dental material for Stratasys 3D printers delivers color and details of natural teeth

Stratasys Ltd. announced the availability of VeroGlaze (MED620) dental material for use with its Objet EdenV and OrthoDesk 3D printers, which print ultrafine 16 micron layers for exceptional detail and surface finish. VeroGlaze enables the 3D printing of dental models with precise A2 teeth color shade to efficiently produce natural looking dental models with fine details and resolution. The new dental material for digital dentistry can be used in conjunction with all open intra-oral, impression and plaster scanners and is optimized for 3D printing models for crowns, bridge restorations, diagnostic wax-ups, and try-in veneers. Designed especially for use in dental and orthodontic solutions, these materials combine accurate detail visualization with high dimensional stability.

NCDMM selects ATK as its partner for phase 2 of Air Force Research Laboratory project

The National Center for Defense Manufacturing and Machining announced that after a competitive solicitation process it has selected ATK’s Aerospace Structures division, based in Clearfield, Utah, as its partner for phase 2 of a project for the Air Force Research Laboratory at Wright-Patterson Air Force Base in Ohio. NCDMM was awarded the effort to oversee the development of a system to automate an inspection method to detect defects in components for aircraft produced by automated fiber placement. The automated inspection system project is part of a 2012 Defense-Wide Manufacturing Science and Technology program awarded to NCDMM through the AFRL at Wright-Patterson AFB. For phase one of the project, NCDMM has been working with Ingersoll Machine Tools, Inc., based in Rockford, Ill., in the development of an on-tool inspection system for AFP.

Built-to-last Surmet reflects aspiration for advanced manufacturing to generate growth

(The Buffalo News) Surmet’s products are made of transparent ceramics, which starts out as synthesized powder produced in a nondescript plant at the rear of a North Buffalo plaza. Suri A. Sastri, the founder, chairman and CEO of Massachusetts-based Surmet, says he is determined to make the Hertel Avenue facility a busier and more successful place for manufacturing the company’s products. “The facility is good. It has tremendous potential. As we grow here, we’ll be able to hire more people and do more stuff. It’s an ideal place for specialty manufacturing.” That is the same message economic development officials are trying to spread about advanced manufacturing in the Buffalo Niagara region. They hope to capitalize on the region’s industrial heritage by cultivating more high-tech production.

Author

Eileen De Guire

CTT Categories

- Construction

- Energy

- Glass

- Manufacturing

Related Posts

Ceramics and glass business news of the week

January 23, 2015

News from the glass and refractory ceramics world

January 18, 2015