Somany Q4 net up nearly 20 percent

Somany Ceramics Ltd. says improved sales resulted in net profit of Rs 10.14 crore ($1.88 million) for the quarter ended March 31, 2013, a year-on-year increase of 19.85 percent. The tile manufacturer’s net sales also rose to Rs 333.71 crore ($61.8 million) for the quarter, compared with Rs 275.86 crore ($51.1) in the year ago period. Net sales for the year rose to Rs 1,046.24 crore ($193.8 million) versus Rs 870.36 crore ($161.2 million) for the last fiscal year. Somany recently acquired a 26 percent stake in two tile producers that increased its annual production capacity of vitrified tiles from 5.3 million to 9.1 million square meters.

Ceram to hold ‘Re-Engineering Materials’ free breakfast forum June 14

The UK-based company Ceram will be holding a free breakfast forum “Re-Engineering Materials—Reduce Waste, Ensure Future Raw Materials Supply and Save Money,” on Friday, June 14 at its headquarters in Penkhull, Stoke-on-Trent. The forum will focus on how raw material shortages and ensuing market price increases are accelerating the need to re-engineer both “waste” and scarce materials in order to meet future industry demands. Andrew Bloodworth, science director for minerals and waste at British Geological Survey, a world-leading geoscience center, will give an independent view on future raw material supply issues. The forum will run from 8:00-11:15 am and include a buffet breakfast, presentations, Q&A session, breakout session with discussion, and networking opportunities.

Shear mode piezo half-rings from American Piezo

APC International is pleased to offer custom shear mode piezo half-rings. Shear mode piezo half-rings are poled around the circumference of the ring. Epoxy silver electrodes are then applied to the top and bottom surfaces of the ring or to the outer and inner diameters of the ring. Alternative electrode materials will be considered upon customer request. Shear mode half-rings can be manufactured from APC 850, APC 855, APC 840, APC 841, and APC 880 materials. If desired, APC’s skilled in-house assembly team can bond two shear mode half-rings using a conductive epoxy to create a shear cylinder. Why consider a shear mode piezo half-ring? Sensing applications: Piezoelectric ceramics poled in shear mode are approximately 20 percent more sensitive than piezoelectric ceramics poled in the standard 3-direction. Piezo motor applications: By bonding two shear mode piezo half-rings together with a conductive epoxy the user can easily create a piezo motor that moves in a circular motion.

AVX introduces the smallest thin-film 10W 3dB directional couplers for wireless communications

AVX Corp., a leading manufacturer of advanced passive components and interconnect solutions, has introduced the smallest thin-film 10W 3dB directional couplers available in today’s market. Based on AVX’s proven thin-film technology, the new 0603 3dB 90° couplers exhibit excellent high-frequency performance in ranges spanning 800-6,000MHz and are currently unique in their ability to provide 10W continuous power handling. “Although designed for use in a wide variety of wireless communications applications, the power handling capabilities, expansive frequency range, and miniature size of our new thin-film 10W 3dB couplers makes them especially attractive for portable communications devices, as this particular market segment continues to demand smaller and smaller components in order to keep pace with consumers’ demands for the smallest and sleekest portable technology available,” says Larry Eisenberger, senior marketing application engineer at AVX. Utilizing land grid array (LGA) packaging technology, AVX’s new 10W 3dB directional couplers feature an inherently low profile, low parasitics, excellent solderability, and improved heat dissipation in addition to self-alignment during reflow. Surface mountable and RoHS compliant, the DB0603N couplers also feature low loss, high isolation, and rugged construction for reliable automatic assembly.

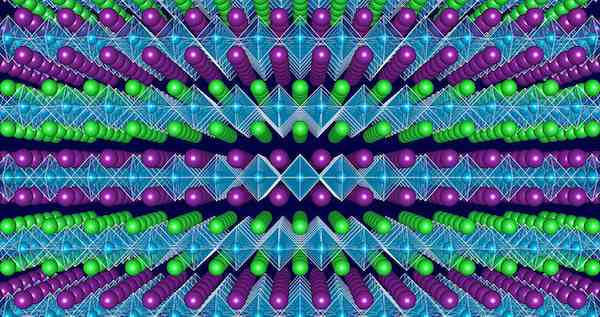

Compact, robust and waterproof: PZT actuators with resistance against exposure to humidity

From medical engineering to mechanical engineering to automotive industry applications—for years piezo-ceramic actuators have been an integral part of a broad range of applications and have proven their effectiveness millions of times over. The only problem: the actuator’s vulnerability to high humidity and the associated reduction in its durability. CeramTec has now succeeded in developing piezo-ceramic actuators with hermetically sealed protection that also offer outstanding long-term stability. This opens up a world of exciting new possibilities in industry and technology. CeramTec piezo-ceramic actuators are made from hundreds of layers of lead zirconate titanate (PZT) films and exhibit a charge separation when subjected to the deformation process by an external force. With a speed of up to 0.1 milliseconds, they can react very quickly while simultaneously exerting a force of one to two kilonewtons. Conventional piezo-ceramic actuators are protected by a polymer or ceramic coating. However, micro fissures may form during operation, allowing water molecules to come into contact with the piezoceramic. The stray current that arises as a result of this process reduces the performance capability of the actuator and can even destroy it.

Deltech control systems now ETL certified by Intertek

Deltech has announced that its control systems is now ETL certified by Intertek. Intertek certifies that Deltech furnace control systems conform to UL508A standards. Standard safety features of Deltech control systems include an emergency stop, door interlock, a safety relay, and isolation switches. Intertek’s ETL Listed Mark is proof of product compliance to North American electrical safety standards. Authorities Having Jurisdiction (AHJ’s) in 50 states and Canada accept the ETL Listed Mark as proof of compliance.

Orton Foundation announces its June refractory course is sold out

The Edward Orton Jr. Ceramic Foundation has announced that its introduction to refractories course is now full. The three-day refractory ceramics short course is scheduled for June 24-26. Foundation officials say that anyone who would like to be added to the wait list and notified when the next course will be held should please contact group.

Company founder, scientist Haldor Topsøe has passed away

It is with profound sadness that we inform you of the passing Haldor Frederik Axel Topsøe, founder of Haldor Topsøe A/S. Topsøe was born on May 24, 1913, and passed away on May 20, 2013, shortly before his 100th birthday, after a brief period of illness. Topsøe will be greatly missed by his entire family and by the company’s employees. He remained actively involved in the daily operations of the company as working chair of the board until a few weeks before his death. During his long life, Haldor Topsøe made significant contributions to the world in terms of technological and scientific innovation to address global challenges within energy, food supply, and the environment. Topsøe has created a truly unique company, a world leader in the field of catalysis, which is instrumental in solving these issues. Henrik Topsøe, his son and vice chair, says,” We have lost the inspiring and loving head of our family—just as science and business have lost a brilliant leader, and the larger world has lost a great man. Due to his perseverance and dedication, and his technological and scientific contributions, my father improved the lives of millions. He has set standards within many fields, and he never stopped pushing the technological boundaries.”

Author

Eileen De Guire

CTT Categories

- Aeronautics & Space

- Education

- Electronics

- Refractories

Related Posts

Ceramics and glass business news of the week

January 23, 2015

News from the glass and refractory ceramics world

January 18, 2015