GE cuts costs, boosts jet efficiency with ceramic parts

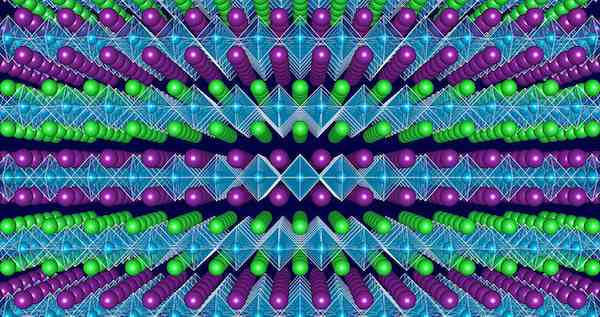

(Wall St Cheat Sheet) In an attempt to reduce maintenance and fuel costs, General Electric is investing in production of ceramic-based parts for its jet engine business. Small-scale production of one part will begin as early as next year in GE Aviation’s planned Asheville, N.C. factory. The ceramic matrix composite components are typically more durable than the nickel alloy parts currently being used, which will cut down maintenance costs for airline companies. They are also more fuel efficient and cut down on emissions—both huge benefits for airline companies. GE’s chief competitor in the jet engine business is United Technologies Corp’s Pratt & Whitney, which has not invested in ceramic matrix composites and instead focused on a new engine design. The “Geared Turbofan Engine” allows for a bigger front fan that could cut fuel use by 15 percent, according to Business Insider. Currently 10 percent of parts used in GE engines are of a composite material. However, most of these composite parts are made of carbon fiber, not CMC’s, and thus can only be used in the “cold” part of the engine, away from where the fuel is burned. The ceramic matrix composites can be used in the “hot” section, where fuel is burned, and are expected to increase the number of composite parts used to 50 percent. The Asheville factory will begin work on one stationary ceramic part early next year, according to The Wall Street Journal. The part will play an integral role in “The Leap” engine by GE, which will come into service in 2016 and is expected to ship 1,200 units in 2017. From there, GE hopes to get up to nine stationary ceramic parts in the “hot” section of the engine.

China takes hard line on cement plants that foul the environment

Seventeen [publicly-traded] cement companies have been found to often violate environmental protection laws by illegally discharging airborne pollutants, according to a report released on Tuesday. The report, conducted by several independent institutes and environmental NGOs and led by the Beijing-based Institute of Public and Environmental Affairs, also accused the companies of failing to disclose environmental information as required. The 17 cement companies have about 170 recorded environmental violations between them. Using the institute’s “Green Stocks Database” on its website, the public can find the environmental supervision records of 850 companies’ subsidiaries and affiliates by typing in the company’s name. The environmental supervision records all come from information published by local environmental protection departments or newspapers quoting official sources. Violations listed in the records include the lack of denitrification facilities, faulty monitoring appliances and excessive emissions. “The State Council recently released 10 measures to control airborne pollution and achieve energy and emissions reductions. The extremely energy-intensive cement, steel, and thermal energy production industries, especially those leading listed companies, need to share the heavy responsibility of reducing emissions and not disappoint the public,” said Ma Jun, director of the Institute. China produces more than half of the world’s cement. According to the National Bureau of Statistics, the country’s cement output from January to May reached more than 866 million metric tons, up by 8.9 percent from the same period last year. The cement industry is among the six most heavily polluting industries that were required by the Environmental Protection Ministry to meet international emission limits from March this year. Dust emissions from the cement industry accounted for about 30 percent of total industrial emissions in 2009.

Settlement with Ash Grove Cement to reduce thousands of tons of air emissions

A new agreement between the EPA and Ash Grove Cement Corp. Today’s will reduce more than 17,000 tons of harmful nitrogen oxides (NOx) and sulfur dioxide (SO2) pollution each year across plants located in Foreman, Ark.; Inkom, Idaho; Chanute, Kan.; Clancy, Mont.; Louisville, Neb.; Durkee, Ore.; Leamington, Utah; Seattle, Wash.; and Midlothian, Texas. According to the Star-Telegram newspaper, “Ash Grove, based in Overland Park, Kan., agreed to pay a $2.5 million penalty and invest about $30 million in pollution control technology at its nine portland cement plants around the country.” The settlement resolves alleged violations of the Clean Air Act, the EPA and the Justice Department says.”[The] settlement will reduce air pollution that can harm human health and contribute to acid rain, haze, and smog,” said Cynthia Giles, Assistant Administrator for EPA’s Office of Enforcement and Compliance Assurance. “The new stringent limits on emissions will lead to less pollution and better air quality for communities across the country.” In addition, Ash Grove has agreed to spend $750,000 to mitigate the effects of past excess emissions from several of its facilities. The settlement requires Ash Grove to meet stringent emission limits and install and continuously operate modern technology to reduce NOx, SO2, and particulate matter (PM). Ash Grove is required to reduce NOx emissions at nine kilns, some of which will have the lowest emission limits of any retrofit control system in the country. In addition, modern pollution controls must be installed on every kiln to reduce PM emissions, and on several kilns to reduce SO2 emissions. n addition, at its Texas facility, Ash Grove will shut down two older, inefficient kilns, while a third will be replaced with a cleaner, newly reconstructed kiln. Ash Grove will also spend $750,000 on a project to replace old diesel truck engines at its facilities in Kansas, Arkansas, and Texas, a change estimated to reduce smog-forming nitrogen oxides by approximately 27 tons per year.

APC offers new stock piezo cylinders

APC International announced that it has increased the variety of standard cylinders available to include a selection of Type I hard material piezoelectric ceramic cylinders. Electrodes are located on the inside surface (+ID) and the outside surface (-OD) of the cylinder. Other poling options are available on request. Typical applications include piezo sensor applications, gas flow sensors, level sensors, NDT/NDE sensors, fiber optic stretching, and fine movement actuators.

Kemet expands capacitor line for high voltage applications

Kemet Corp., a leading manufacturer of tantalum, ceramic, aluminum, film, paper, and electrolytic capacitors, today announced the expansion of its surface mount high voltage multilayer ceramic capacitor (MLCC) portfolio. To meet the growing demand for higher capacitance in surface mount high voltage MLCCs, Kemet has increased its capacitance offering by up to five times across most of its X7R dielectric platform. Available capacitance has been increased in EIA 1206 thru 2225 case sizes with rated voltages up to 3000VDC. “Advances in Kemet’s base-metal-electrode (BME) X7R high voltage technology have led to the development of some of the highest capacitance values available in the industry, including first-to-market,” says Reggie Phillips, Kemet specialty product manager. “These new CV values will promote optimization and downsizing opportunities of existing designs and promote usage in applications requiring capacitance values previously unattainable in a high voltage ceramic capacitor,” continues Phillips. Kemet high voltage MLCC devices exhibit low leakage current and low ESR at high frequencies. As an option, they are available with Kemet’s flexible termination technology which inhibits the transfer of board stress to the rigid ceramic body, therefore mitigating flex cracks which can result in low IR or short circuit failures. Tin-lead termination finish is also available for higher reliability applications. Typical applications for the capacitors include power supply, LCD fluorescent backlight ballasts, HID lighting, telecom equipment, industrial and medical equipment/control, LAN/WAN interface, analog and digital modems, and automotive lighting. Typical markets are alternative energy, industrial/lighting, medical, telecommunications, transportation, and defense and aerospace.

DayLube nanoceramic grease available in a range of sizes

DayLube high performance grease from Dayton Progress Corp., Dayton, Ohio, uses nanoceramic particles that act as sub-microscopic ball bearings to provide continuous lubrication to steel surfaces, is available in a full range of sizes including 16-ounce tubes and jars, as well as gallon and five gallon containers. The product is said to be chemically inert and have a lower coefficient of friction at all temperatures than traditional PTFE greases. It maintains its viscosity across the full temperature range and does not soften or run out: After 100,000 production strokes it shows no evidence of breaking down. This proven nanoceramic lubricating grease provides very good friction reduction and wear-resistance, making it ideal for a wide range of industrial and commercial applications. It operates in temperature ranges from -40°F to 800°F, and the nanoceramic particles remain intact to 2500°F. It survived the ASTM 4-ball weld test with no weld and minimal damage to all ball bearings. The product is said to have high load-bearing properties, a low dielectric constant, does not contain metal or silicone and is resistant to steam, acids, and most chemical products. Applications include construction and earthmoving equipment, landscape contracting equipment, agricultural, automotive, aerospace, industrial machinery, general manufacturing, marine, material handling, stamping & fabricating, and more.

Christie pushes the envelope with newest tiled display solutions with Gorilla Glass

(Geeks World) Christie continues to stay ahead of the industry curve with the introduction of the next generation of Christie Jumpstart, the Christie FHD551-XG with Corning Gorilla Glass, and the company’s first turnkey multi-touch video wall solution. An industry first with the smallest image-to-image gap of any bonded LCD panel, the Christie Multi-touch Video Wall Solution comprises a 4-unit wide by 1-unit high row of portrait-mounted 55-inch LCD panels with bonded Corning Gorilla Glass, Christie Interactivity Kit, Christie Jumpstart, and the mounting hardware for a wall-mounted or freestanding display. The first 55-inch super-narrow bezel LCD display for tiled video walls with bonded Corning Gorilla Glass, the Christie FHD551-XG is ideal for touch screens including broadcast sets and high-traffic public spaces including hotels, restaurants, museums, airports and railway stations. “Christie JumpStart targets architectural markets including museums, universities, stadiums, corporate offices and retail stores needing high resolution, reliable content playback across large video walls,” says Richard Heslett, senior product manager, Christie. “Rental stagers will also benefit from the speed and ease of setup of JumpStart, and its support for unique display configurations.”

Old industry offers new options of products, green technology

(Pittsburgh Post Gazette) American-based Crossville teamed up with Japanese company Toto to create ceramic tile that purifies the air and destroys stains. A special coating that is baked onto the surface of the tile is activated by light. Crossville uses recycled content in its products. Digital inkjet printing has also revolutionized the manufacturing of ceramic and porcelain tile. The biggest style trend now is the look of wood, with reclaimed wood being a favorite for wall and floor tiles. Like pre-washed jeans, it’s not enough to imitate natural materials such as cement, stone and wood. They must also have a time-worn patina. Florida Tiles showed Magnolia, a printed wood look that comes in a variety of colors. Fioranese’s Old Wood series is nearly indistinguishable from the real thing; even wood’s texture is replicated.

Surmet wins ACerS Corporate Technical Achievement Award

The American Ceramic Society’s (ACerS) 2013 Corporate Technical Achievement Award has been awarded to Surmet Corp for its development and commercialization of ALON aluminum oxynitride transparent optical ceramic. The award recognizes and honors achievements that show significant technical merit and represent a gain to society through commercialization of the technology within the preceding eight years. ALON transparent armor provides higher than 50% weight savings over glass based armor, improving system performance and cutting life-cycle cost.

CTT Categories

- Cement

- Electronics

- Energy

- Manufacturing

Related Posts

Ceramics and glass business news of the week

January 23, 2015

Ceramics and glass business news of the week

January 16, 2015