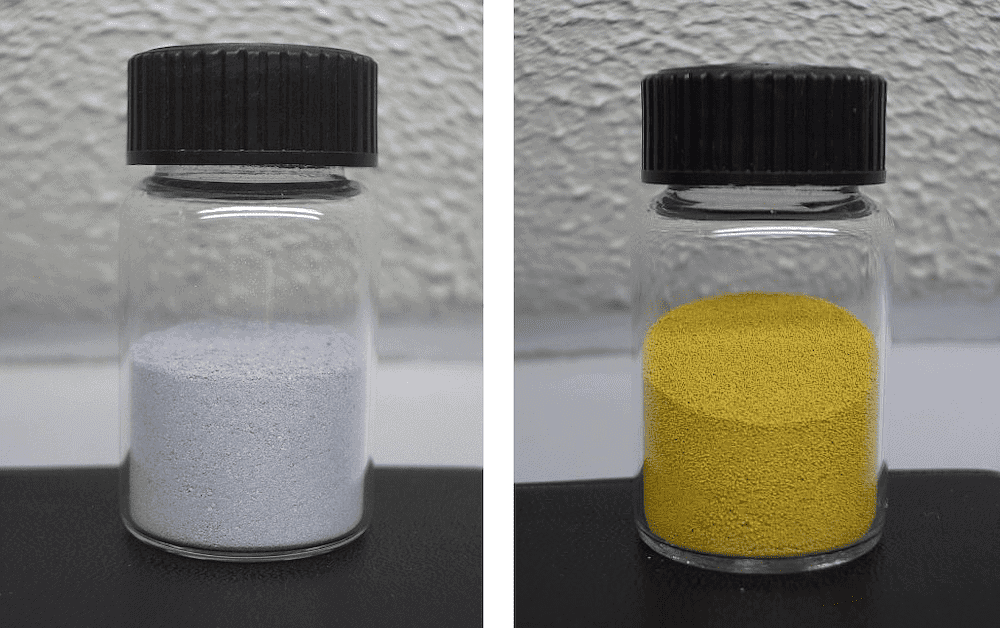

[Image above] Examples of oxides used as catalysts: molybdenum trioxide powder (left) and vanadium pentoxide powder (right). Credit: Wikimedia, W. Oelen (CC BY-SA 3.0)

Oxygen can be a very troublesome element for researchers, as it readily reacts with most other elements and forms unwanted compounds. On the other hand, this same reactivity is why oxides find wide application as heterogeneous catalysts for numerous chemical reactions.

Catalysts are substances that increase the rate of a chemical reaction without themselves undergoing any permanent chemical change. Homogeneous catalysts are present in the same phase as the reactants and products, usually liquid. In contrast, heterogeneous catalysts are present in a different phase, usually solid. For this reason, it is much easier to separate heterogeneous catalysts from the product after reaction than homogeneous catalysts.

Various types of catalysts are used depending on the chemical reaction to be triggered. For example, oxidation catalysts, which are used predominantly for destruction of volatile organic compounds and carbon monoxide, commonly contain vanadium and molybdenum oxides. Acid catalysts, which are mainly used for organic chemical reactions, can contain tungsten oxides and phosphates. Base catalysts, which are widely used in biodiesel production, often contain magnesium and zinc oxides.

Contrary to common assumption, the entire surface of a heterogeneous catalyst is not involved with the chemical reaction. Only certain areas called “active sites” are involved. So, counting how many active sites a catalyst has allows researchers to determine how quickly a reaction will take place. (Specifically, they can determine the reaction turnover frequency [TOF], or how many molecules are reacted per surface site per unit of time.)

Titration methods using chemisorption probes like H2, O2, CO, and N2O are a standard way to count the number of active sites on supported metal catalysts. However, these methods have not been successful with oxide catalysts because the chemisorption probes that work well with metals do not adsorb well on oxides.

Fortunately, a solution for determining the number of active sites on oxides appeared in the literature in the 1980s. Researchers found that adsorption of methanol (CH3OH), as well as other small alcohols, on oxide catalysts allowed them to count the number of active sites and also provided structural reactivity information. (Examples here, here, here, and here.)

Despite this discovery and some resulting advances, methanol chemisorption still is not commonly used to characterize oxide catalysts. “Consequently, most of the catalysis literature for oxides just presents the data as qualitative selectivity vs. conversion plots rather than determining the TOF values, … This represents a missed opportunity by the catalysis community studying oxide catalysts,” Israel E. Wachs writes in a recent paper.

Wachs is the G. Whitney Snyder Professor of Chemical and Biomolecular Engineering and director of the Operando Molecular Spectroscopy and Catalysis Research Lab at Lehigh University. In the recent paper, Wachs looks to expand on this missed opportunity by providing a mini review of the available data concerning surface site density and corresponding TOF values for methanol oxidation by different types of oxide catalysts.

As a disclaimer, Wachs notes that much of the cited data comes from experiments conducted in his own laboratory (1) to allow for a consistent set of well-defined oxide catalysts and (2) because most publications on quantitative methanol chemisorption since 2000 have come from his laboratory. “Comparisons with published findings from other groups will also be made when such data are available,” he adds.

Wachs splits the review into sections that focus on three types of oxide catalysts: unsupported pure bulk oxides (one-component oxides), supported oxides (one-component and multicomponent), and unsupported bulk mixed oxides.

Unsupported catalysts are ones in which the entire catalyst structure consists of the catalytic material. Supported catalysts are ones in which the catalytic material is affixed to another material with a high surface area that provides mechanical stability.

Some highlights from the mini review include the following.

Fewer number of active sites on one-component oxides than on metals

The typical number of active surface sites on isotropic one-component oxides was found to be about 0.7 × 1015 sites/cm2, which is about half of that for metals (about 1.2 × 1015 sites/cm2). This finding is attributed to the fact the surface site density on oxides is less than on metals.

The number of active surface sites on anisotropic one-component oxides such as MoO3, V2O5, and ZnO is even lower—about 0.1 × 1015/cm2. This finding is attributed to the fact there are much fewer active exposed surface planes due to the presence of coordinatively saturated sites.

Similarities and differences in TOF values for supported vs. unsupported mixed bulk oxides

For redox catalysts, the TOF values for supported oxides and their corresponding bulk mixed oxides were very similar given their common coordinating ligand. In contrast, the TOF values for acid catalysts were very different, with the bulk mixed oxides much more active.

Room to expand beyond current oxides

To date, researchers have focused mostly on vanadium and molybdenum oxides for oxidation catalysts, and tungsten oxides for acid catalysts. Wachs says future studies need to expand the database of oxides used in catalysts and suggests other redox cations (e.g., chromates, rhenates) and acidic cations (e.g., niobates, aluminates) as possibilities.

The paper, published in Journal of Catalysis, is “Number of surface sites and turnover frequencies for oxide catalysts” (DOI: 10.1016/j.jcat.2021.12.032).

Author

Lisa McDonald

CTT Categories

- Manufacturing