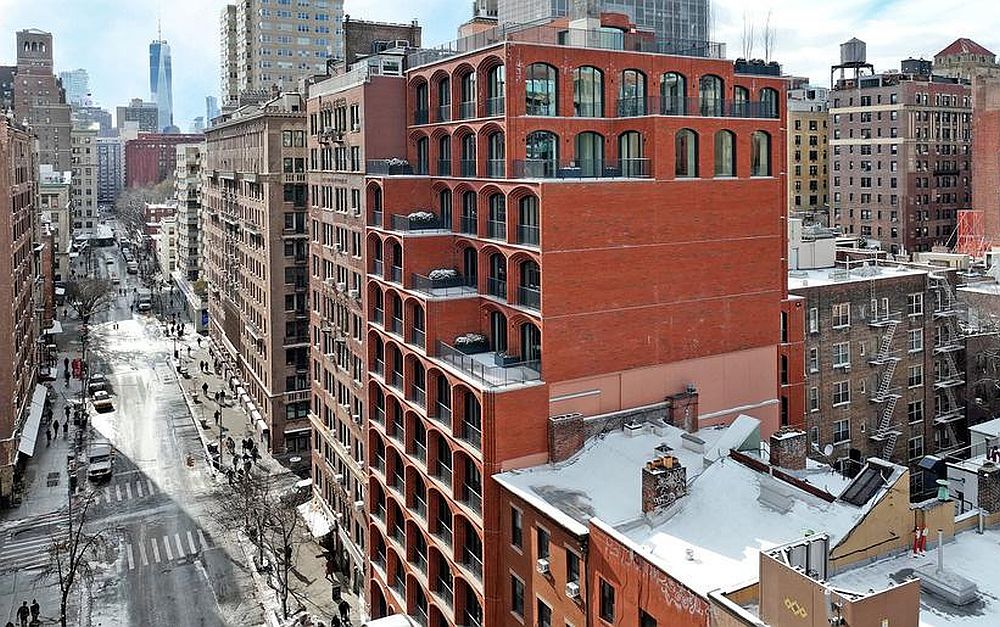

[Image above] Cracks due to the alkali-silica reaction in concrete. The current standard method for monitoring this reaction is destructive and time consuming. Credit: Draceane, Wikimedia (CC BY-SA 4.0)

As funding ramps up to identify and facilitate technologies for advanced nuclear reactors, preventing alkali-silica reactions (ASR) in concrete remains an important area of research.

ASR is a common cause of concrete deterioration. It occurs when aggregates containing certain forms of silica react with hydroxyl ions in the alkaline cement pore solution. The reaction produces a gel, which absorbs water from the surrounding environment and expands. Expansion of the gel exerts pressure on the concrete, causing it to crack and fail.

Concrete is an essential material used to safeguard nuclear facilities. As such, even though nuclear power plant failure from ASR is uncommon—only one commercial nuclear plant in the United States is known to suffer from ASR—ASR prevention remains an important concern when constructing new nuclear plants.

Much research focuses on designing concrete that is resistant to ASR because once an existing concrete structure is affected, there is currently no cure and replacement of the concrete is difficult. However, new methods for detecting and monitoring ASR are needed as well because current industry practice of extracting concrete cores for analysis is costly, time consuming, and also damages the structure.

Recent work has investigated various methods of quantitative nondestructive evaluation, including linear and nonlinear ultrasonic testing and microwave techniques. Though these techniques offer potentially promising results, “each of these methods suffers from limitations that prevent a single technique to be the sole reliable method for [nondestructive evaluation] of ASR,” researchers write in a recent paper.

The researchers, from Argonne National Laboratory, note in their paper that one group recently proposed a combined multiphysics approach to overcome the limitations of relying on a single method. “Following this approach, this work further investigates an alternative nondestructive method for ASR, which could be used in conjunction with other [quantitative nondestructive evaluation] techniques applicable to concrete structures,” they write.

The method they investigated is based on electrochemical impedance spectroscopy, which can be used to determine a material’s electrical conductivity. Previous studies on electrical conductivity of concrete found that conduction occurs primarily through the alkaline pore solution network. The Argonne researchers hypothesized the ASR-produced gel would block these pole solution conduction channels, which could be revealed through bulk resistivity measurements.

They conducted one-sided electrochemical impedance spectroscopy measurements on a set of accelerated ASR small concrete prisms that were developed from a highly reactive concrete mixture according to ASTM C1293 standard. A complementary set of prisms was developed for petrography and damage rating index assessment and for pore solution extraction and analysis.

Based on the results, the researchers determined that ASR does alter the electrical resistance of concrete, creating a signature that can be used to distinguish and locate ASR. In an Argonne press release, Argonne principal electrical engineer Alexander Heifetz says they are now working with industry to see if the approach works on a greater range of geological samples than those used in the study.

“We have the potential to develop this into a technique that can be used on actual structures,” he says.

The paper, published in Materials and Structures, is “Monitoring accelerated alkali-silica reaction in concrete prisms with petrography and electrical conductivity measurements” (DOI: 10.1617/s11527-022-01942-8).

Author

Lisa McDonald

CTT Categories

- Cement

- Construction