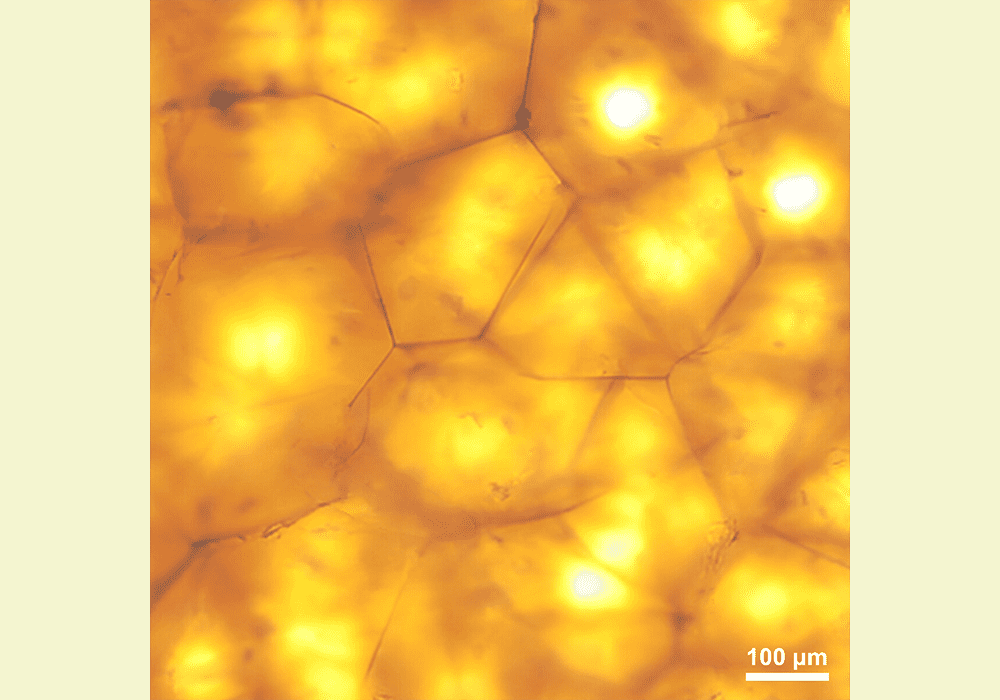

[Image above] Microscopy image of a BaAl2Si2O8–LaF3 transparent ceramic derived from a hybridized glass. Credit: Shifeng Zhou

In the January/February 2023 issue of the ACerS Bulletin, ACerS Fellow Akio Ikesue, president of World-Lab. Co., Ltd. in Nagoya, Japan, describes the recent advances in and potential of optical-grade ceramics.

Optical-grade ceramics are polycrystalline ceramics with an optical performance equal to or greater than that of single crystals. Though most materials scientists traditionally believed that the scattering of ceramics with grain boundaries would always be much larger than that of single crystals, since the 1990s, researchers found that low optical loss and high optical uniformity can be achieved in ceramics synthesized via solid-state reaction processes.

However, the current and primary sintering methods used to obtain optical-grade and (lesser quality) transparent ceramics are restricted by extreme processing conditions such as high temperature and pressure or spark plasma, which is necessary to eliminate undesired micropores.

Moreover, barring 3D printing techniques, these methods suffer from difficulties in material reshaping, and the available products are usually in bulk form. Thus, downsizing optical-grade and transparent ceramics to the microscale level remains challenging.

In contrast to these conventional processing routes, the crystallization of glass is a newer approach for creating transparent ceramics that holds several advantages. For example,

- Accessible processing conditions. Producing transparent ceramics through glass crystallization only requires heat treatment at atmospheric pressure, and the heat-treatment temperature is commonly below 1,000°C.

- Easily downsized. Without the restriction of pressurization conditions, downsizing the transparent ceramics becomes easier and more convenient.

- Easily shaped. Glass has the advantage of being easily shaped through mature molding technologies. By using these technologies to shape the precursor glass, transparent ceramics of different shapes can be readily achieved.

However, there are challenges to satisfying the harsh and conflicting requirements of excellent glass-forming ability and inherent dense crystallization habits while fulfilling the requirements for high transparency. So, researchers have produced only a limited number of glass-derived transparent ceramics to date (such as here, here, and here).

In a new paper, researchers from South China University of Technology and Zhejiang University in China, as well as a colleague from Nanyang Technological University in Singapore, presented a general strategy for constructing dual-phase transparent ceramics from hybridized aluminosilicate glasses consisting of oxides and fluorides.

The researchers explain that compared to other glass systems, hybridized glasses containing oxides and fluoride exhibit strong flexibility in the crystallization process.

“The introduction of fluoride in the hybridized glass breaks the network of glass, which causes a lower viscosity of the glass matrix, making diffusion and migration easier. Thus, the hybridized glass has lower energy barrier to crystallize,” they write.

Additionally, “the notable contrast in the crystallization tendency of oxides and fluoride from the oxide matrix allows modification of the crystallization coordinate curve into various discrete stages, enabling dense crystallization under mild conditions,” they add.

For their study, the researchers synthesized hybridized BaAl2Si2O8–LaF3 (BASL) glasses using the melt-quenching method. They then heat treated the glass at various temperatures between 780°C and 860°C for 2.5 hours in air to induce crystallization.

The sample heat treated at 860°C achieved the highest crystallinity (~92%). Microscopy analyses revealed it featured a multiscale and interconnected microstructure consisting of nanoscale LaF3 crystalline domains homogeneously embedded in the microscale BaAl2Si2O8 crystalline phase.

Interestingly, the refractive indexes of the BaAl2Si2O8 and LaF3 crystals were 1.61 and 1.60, respectively, so scattering was avoided between them. Additionally, the refractive indexes of the glass and transparent ceramic were measured to be 1.603 and 1.598 at a wavelength of 633 nm, respectively, and this similarity contributed to the good transparency of the sample.

Once analysis of the bulk samples was completed, the researchers used the same process to crystallize glasses with a fiber geometry. The resulting transparent ceramic fiber consisted of BaAl2Si2O8 and LaF3 in multiple crystalline phases but with an overall highly homogeneous crystalline structure. Like the bulk sample, the transparent ceramic fiber also demonstrated excellent optical transparency.

Based on these encouraging results, the researchers tried fabricating other hybridized glass compositions. The new compositions—BaAl2Si2O8 replaced with SrAl2Si2O8 (SASL) and LaF3 replaced with GdF3 (BASG)—also demonstrated high crystallinity (89% and 93%, respectively) and optical transparency. Achieving these results required only a small modification to the ideal heat treatment temperature (lowered from 860°C to 830°C and 850°C, respectively). Transparent ceramics based on the hybridized systems of Ba3Si5O13–BaF2 and NaAlSiO4–LiF were also successfully fabricated.

The researchers also demonstrated the possibility of functionalizing the transparent dual-phase ceramics through doping with various luminescent rare earth activators. BASL transparent ceramics doped with cerium, europium, terbium, dysprosium, and samarium under excitation with ultraviolet light (365 nm) exhibited bright blue, azure, aquamarine, yellow, and orange luminescence, respectively.

Additionally, the researchers used the transparent ceramic to construct a radiographic imaging device and successfully demonstrated its application for X-ray imaging.

Ultimately, the researchers concluded that this strategy demonstrates a wide variety of useful features, including

- Generality, where the strategy is suitable for transparent ceramics and fibers with various chemical compositions, phases, microstructures, and morphologies;

- Easy processing, where the strict external conditions of conventional ceramic technology, such as high temperature and pressure, can be avoided; and

- Potential for further functionalization, where the ceramic can be activated with luminescent centers for different photonics applications.

“This study is an important milestone in developing novel transparent optical ceramics,” says Shifeng Zhou, senior author and professor at South China University of Technology, in an email.

Zhou says that the application of this fabrication technique to more material systems is underway. Ideally, in the future, this fabrication strategy will provide “a new technical route for the preparation of commercial and industrialized transparent ceramic products,” he says.

The paper, published in Advanced Materials, is “Hybridization engineering of oxyfluoride aluminosilicate glass for construction of dual-phase optical ceramics” (DOI: 10.1002/adma.202205578).

Author

Lisa McDonald

CTT Categories

- Glass

- Manufacturing

- Optics